- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Aug . 05, 2025 04:00 Back to list

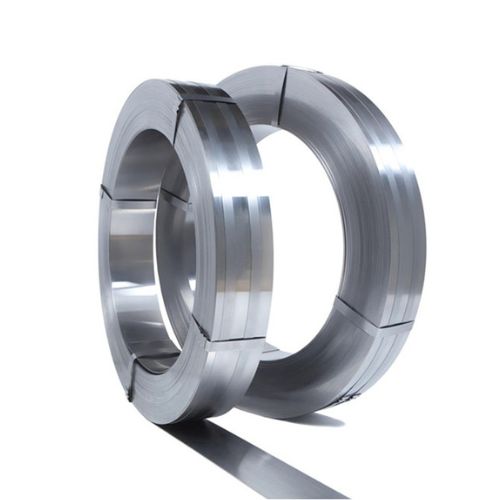

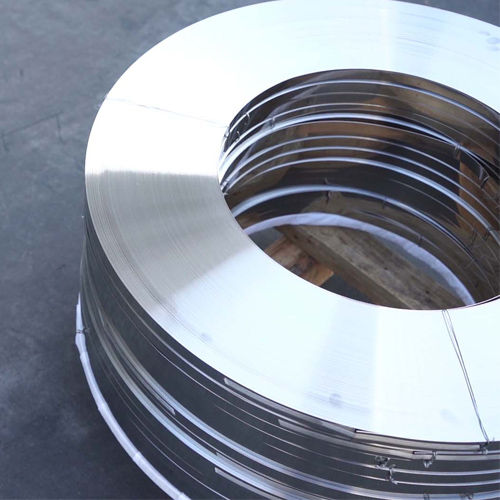

Quality 201 Stainless Steel Strip | Durable & Cost-Effective

In the ever-evolving world of stainless steel materials, 201 stainless steel strip has established itself as a cost-effective, versatile solution for numerous industries. This article offers an in-depth review of 201 stainless steel strip, comparing it against popular alternatives like 304 stainless steel strip and 316 stainless steel strip, while showcasing advanced manufacturing processes, certified quality, and real-life application cases from leading China stainless steel strip manufacturers.

1. Industry Trends: The Rise of 201 Stainless Steel Strip in the Global Market

Due to increasingly stringent environmental standards and a drive for material efficiency, the demand for high-quality, corrosion-resistant, and cost-effective stainless steel materials has soared. 201 stainless steel strip has gained global traction for its optimal balance between mechanical strength, formability, and price point. According to the International Stainless Steel Forum (ISSF), global stainless steel melt shop production reached over 56 million metric tons in 2023, with China contributing more than 60% of global output, driving innovation in china stainless steel strip manufacturing.

Figure 1: Global Stainless Steel Strip Consumption by Grade, 2023 (Source: ISSF, Metal Bulletin)

2. What is 201 Stainless Steel Strip? Core Properties & Industry Data

201 stainless steel strip is an alloy composed mainly of iron, chromium (~16-18%), nickel (~3.5-5.5%), and manganese, designed for corrosion resistance and mechanical strength. Thanks to substantial advancements in cold rolling and precision slitting, leading stainless steel strip coil suppliers from China can now offer exceptionally tight tolerances and custom surface finishes, conforming with ISO 9001, ASTM A240, and JIS G4304 international standards.

- High formability & ductility

- Good corrosion resistance in mild environments (superior to carbon steel, slightly less than 304 alloy)

- Non-magnetic in the annealed condition

- Excellent cost-performance ratio

- Easy fabrication and weldability

2.1 Technical Specifications: 201 Stainless Steel Strip Parameters

| Property | 201 Stainless Steel Strip | 304 Stainless Steel Strip | 316 Stainless Steel Strip |

|---|---|---|---|

| Chemical Composition | Cr: 16-18% Ni: 3.5-5.5% Mn: 5.5-7.5% Fe: bal. |

Cr: 18-20% Ni: 8-10.5% Fe: bal. |

Cr: 16-18% Ni: 10-14% Mo: 2-3% Fe: bal. |

| Yield Strength (MPa) | ≥260 | ≥205 | ≥205 |

| Tensile Strength (MPa) | 520-980 | 515-690 | 515-690 |

| Elongation (%) | ≥40 | ≥40 | ≥40 |

| Hardness (HV) | 200-250 | 180-200 | 180-200 |

| Corrosion Resistance | Good | Excellent | Superior |

| Price ($/ton)* | 1,250-1,800 | 2,250-2,500 | 3,200-4,000 |

*Q1 2024 average market quotations, actual price may vary by surface finish and order size

3. 201 Stainless Steel Strip Manufacturing Process (Flowchart & Explanation)

Raw Material Selection

Iron, Chromium, Nickel, Manganese

Melting & Casting

Electric Arc Furnace, Continuous Casting

Hot Rolling

Reduces slab into rough coil

Cold Rolling

Achieves target thickness, improves flatness

Annealing & Pickling

Refines grain structure, removes scale

Slitting & Surface Finish

Precision trimming and desired finish (BA, 2B, No.4, etc.)

Quality Inspection

ISO/ASTM tests: mechanical, dimensions, surface defects

Quality Assurance: Every 201 stainless steel strip undergoes strict in-line and off-line inspection—tensile test, microstructure analysis, surface roughness (Ra) measurement, Edx for composition—ensuring compliance with ISO 9001 and ASTM A666 standards.

▶ Watch a short process video demonstration (YouTube)

3.1 Key Technical Advantages

- Material Stability: Enhanced delta-ferrite structure ensures improved resistance to intergranular corrosion after welding

- Surface Quality: Advanced cold rolling achieves uniform thickness (±0.02 mm tolerance achievable)

- Cost Savings: Lower nickel content delivers substantial price advantage against 304/316 alloys

- Sustainability: Up to 80% recycled steel content, supporting ESG supply chain targets

- Formability: Suitable for deep drawing, stamping, and precision formed components

4. Manufacturer Comparison: China Stainless Steel Strip Suppliers vs. International Markets

- Certification: ISO 9001:2015, SGS, BV, TUV, PED/EN10204

- Precision Processing: Width tolerance up to ±0.05mm, thickness up to ±0.02mm

- Stock Availability: Standard sizes always available for immediate shipping

- Global References: Serving over 37 countries and top industrial clients (e.g., Siemens, SANY, Emerson)

- Warranties & After-sales: Comprehensive product insurance & technical support

| Feature | China Manufacturers (e.g. PuxingClamp) | European Mills | US/JP Mills |

|---|---|---|---|

| Lead Time | 3-15 Days (in-stock); 20-30 days (custom) | 5-10 Weeks | 6-12 Weeks |

| MOQ | 1 Ton | 3 Tons | 2 Tons |

| Technical Support | 24/7, global on-site | Office hours only | Office hours only |

| Certifications | ISO, SGS, PED, TUV | ISO, EN, DIN | ASTM, JIS |

| Custom Coil Sizes | Width from 3 mm, thickness 0.05-3 mm | Width from 6 mm, thickness up to 5 mm | Width from 6 mm, thickness up to 4 mm |

| Export Experience | 20+ Years | 50+ Years | 60+ Years |

Figure 2: Radar Chart – Key Property Comparison (201 vs. 304 vs. 316 Stainless Steel Strip)

5. Customization & Typical Application Scenarios

Thanks to advanced CNC slitting and precision coil handling, 201 stainless steel strip can be tailored to diverse customer requirements:

Available thickness: 0.05–3.0 mm

Width: 3.0–600 mm

Surface: 2B, BA, 8K mirror, No.4 brushed, Slit Edge, Mill Edge

- Thickness Tolerance: ±0.02 mm

- Width Tolerance: ±0.05 mm

- Surface Ra: ≤0.3 µm achievable

Figure 3: Evolution of Best Achievable Thickness Tolerances (China Manufacturers)

5.1 Representative Application Fields

- Household & Kitchen Appliances: Washing machine drums, rice cooker liners, cutlery shearing

- Automotive Industry: Hose clamps, trim, channel supports, exhaust clamps

- Electronics: EMI/RFI shielding, battery contact strips

- Building & Decoration: Elevator trims, balustrades, signage

- Petrochemical: Gaskets, heat exchanger shim, floating roof seal strips

- Pipeline Systems: Seawater and municipal pipeline banding

- Food Processing: Conveyor bands, chute linings

Case Study: PuxingClamp's 201 Stainless Steel Strip in Large-Scale Water Supply Systems

- Client: Municipally-owned water utility, South Asia

- Challenge: Previous carbon steel banding corroded in 18-24 months; recurring repair cost

- Solution: Switched to 201 stainless steel strip (2B surface, 1.2mm thick, 50mm wide, slitted edge)

- Result: Banding lifespan extended 6x, repair cycle >10 years, total maintenance cost reduced by 64%. All installed strips passed SGS salt spray test (>120 hrs)

✔ Conclusion: Upgrading to 201 stainless steel strip delivered outstanding anti-corrosion performance, lifecycle savings, and compliance with ANSI/AWWA C219 pipeline standards.

- All materials strictly comply with ISO 9001, ASTM A240/A666 & customer’s specified standards.

- 3-year warranty for 201 stainless steel strip under normal use.

- Custom cut-to-length & laser marking available upon request.

- Full certificate file (COC, Mill test, QA/QC photos) provided for each batch.

- Responsive customer support: reply within 2 hours, technical guidance available globally.

6. Frequently Asked Technical Questions (FAQ)

7. Delivery, Quality Assurance & Customer Service

- Average delivery time: In-stock sizes: 3–7 working days | Custom: 10–20 working days.

- Documentation: Full Material Test Reports (MTR), Mill Certificate, SGS/Intertek/Third-party inspection available.

- Packaging: Secure, corrosion-resistant, export-grade packaging; custom crate/coil sizes available.

- Global Logistics: DDP, CIF, FOB and Air Express shipping to 92+ countries.

- Warranty: 3-year warranty on all 201 stainless steel strip, free replacement for proven material defects.

- Support Channels: 24/7 online; on-site installation training (for large corporate customers)

- ISSF World Stainless Steel Data 2023: https://www.worldstainless.org/Files/issf/non-image-files/PDF/ISSF_Statistics_2023.pdf

- ASTM A240/A666 Standards: https://www.astm.org/standards/a240

- Excellent in-depth forum discussion on stainless grades and selection: Practical Machinist Forum

- Application research: "Corrosion Performance of 201 vs 304 and 316 Stainless Steel Strips." ResearchGate

- Manufacturer technical data: PuxingClamp Product Page

-

Large Stainless Steel Adjustable American Type Hose Clamp | Hebei Pux Alloy Technology Co., Ltd

NewsAug.05,2025

-

Quality 201 Stainless Steel Strip | Durable & Cost-Effective

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025