- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

aŭg . 22, 2025 11:20 Back to list

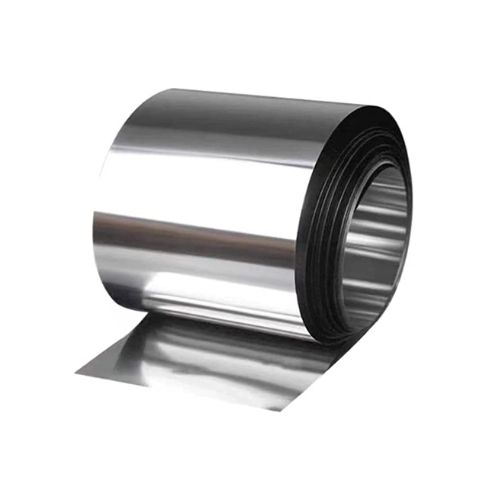

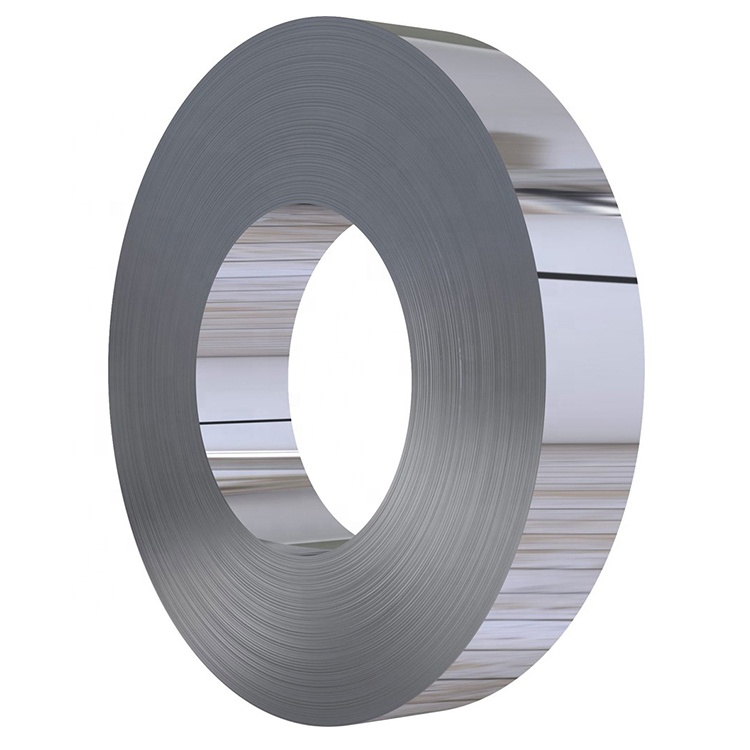

Precision High Quality Stainless Steel Strip Coils & Rolls

Navigating the Landscape of stainless steel strip coil: Trends and Innovations

The global demand for high-performance materials continues to drive innovation in the metallurgical sector. Among these, the stainless steel strip coil stands out as a critical component across a myriad of industrial applications. Its unique combination of corrosion resistance, strength, and aesthetic appeal makes it indispensable. Recent industry trends indicate a significant shift towards more specialized grades, ultra-thin precision coils, and sustainable manufacturing practices, driven by sectors such as automotive, electronics, and renewable energy. The market is increasingly seeking suppliers capable of delivering not just standard products, but also customized solutions that meet stringent technical specifications and environmental regulations.

As a leading stainless steel strip factory, we observe a growing emphasis on high-precision processing and advanced surface finishes. This demand is particularly pronounced for applications requiring exact tolerances and superior surface quality, such as in the production of medical devices, intricate electronic components, and high-end consumer goods. The drive for lightweighting in transportation and energy sectors also propels the need for stronger, thinner gauges of stainless steel, without compromising durability or integrity. This necessitates sophisticated manufacturing capabilities and rigorous quality control throughout the production chain, from raw material sourcing to final product delivery.

Comprehensive Manufacturing Process of Stainless Steel Strip Coil

The production of a high-quality stainless steel strip coil is a complex, multi-stage process that demands precision engineering and stringent quality control at every step. This intricate journey transforms raw materials into highly specialized products suitable for demanding industrial applications.

1. Raw Material Selection and Melting

The foundation of any superior stainless steel product begins with meticulously selected raw materials. High-grade iron ore, chromium, nickel, molybdenum, and other alloying elements are chosen based on the desired stainless steel grade (e.g., 304, 316, 430). These materials are melted in electric arc furnaces (EAF) or induction furnaces. Oxygen blowing, decarburization, and slag removal are carefully controlled to achieve the precise chemical composition required. Advanced spectrometric analysis ensures that the molten metal adheres strictly to established international standards such like ASTM A240/A240M and EN 10088.

2. Casting and Hot Rolling

Once the desired alloy composition is achieved, the molten steel is continuously cast into slabs. These slabs are then reheated and passed through a series of hot rolling mills. Hot rolling reduces the slab thickness, refines the grain structure, and improves mechanical properties. During this stage, precise temperature control and rolling schedules are critical to prevent defects and achieve uniform dimensions. The product at this stage is a hot-rolled strip, often referred to as a "black coil" due to its oxidized surface.

3. Annealing and Pickling (Hot Rolled)

The hot-rolled strip undergoes annealing, a heat treatment process that softens the steel, relieves internal stresses, and recrystallizes its microstructure. This is followed by pickling, where the oxidized surface scale (mill scale) is removed using acid baths. This process ensures a clean, uniform surface, preparing the material for subsequent cold rolling operations and enhancing its corrosion resistance.

4. Cold Rolling

Cold rolling is a crucial stage for achieving precise thickness, superior surface finish, and improved mechanical properties. The annealed and pickled hot-rolled strips are passed through tandem cold rolling mills at room temperature. This process significantly reduces the strip thickness, enhances surface smoothness, and can introduce work hardening to increase strength, particularly relevant for `stainless spring steel strip` applications. Multiple passes may be required, with intermediate annealing cycles to prevent excessive hardening and allow for further deformation.

5. Annealing and Pickling (Cold Rolled) & Finishing

After cold rolling, the strip undergoes another annealing and pickling cycle. This final annealing step restores ductility, improves corrosion resistance, and ensures optimal mechanical properties. Depending on the desired end-product, further finishing processes include skin pass rolling (to improve surface luster and flatness), tension leveling, and polishing (e.g., BA, 2B, NO.4, Mirror finish). These finishing treatments are critical for achieving a `high quality stainless steel strip roll` that meets aesthetic and functional requirements.

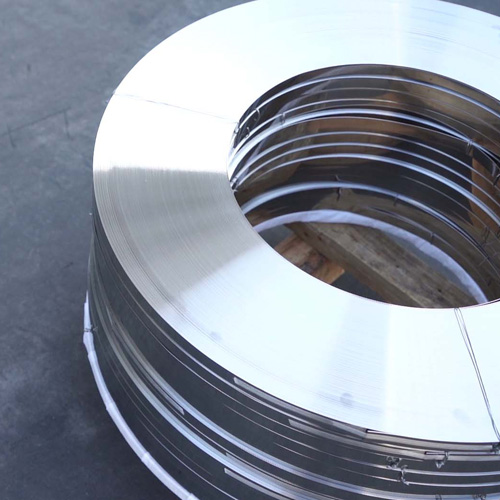

6. Slitting, Inspection, and Packaging

The wide cold-rolled and finished coils are then precisely slit into narrower strips according to customer specifications, creating `precision stainless steel strip`. Advanced slitting machinery ensures minimal burring and consistent width tolerances. Each slit coil undergoes rigorous final inspection, including visual checks, dimensional measurements, and mechanical testing (e.g., tensile strength, hardness, elongation). Non-destructive testing methods, such as eddy current or ultrasonic testing, may also be employed for critical applications. Finally, the coils are carefully packaged to prevent damage during transit, often with protective wraps and robust crating to ensure delivery in pristine condition.

Our manufacturing processes adhere strictly to international standards such as ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management, ensuring consistent product quality and responsible production. The typical service life for our stainless steel strip coils, when properly applied and maintained in appropriate environments, can extend beyond 20-30 years, showcasing their durability and inherent corrosion resistance.

Technical Specifications and Performance Parameters

Understanding the technical parameters of stainless steel strip coil is crucial for optimal material selection in B2B applications. These specifications dictate the material's suitability for various operating environments and mechanical demands.

| Parameter | Description | Common Range / Value | Relevant Standard |

|---|---|---|---|

| Material Grade | Alloy composition determines properties | 304, 304L, 316, 316L, 430, 201, 202 | ASTM A240/A240M, EN 10088-2 |

| Thickness | Gauge of the strip | 0.1 mm to 6.0 mm (Cold Rolled) | ASTM A480/A480M |

| Width | Slit width of the coil | 10 mm to 1500 mm | ASTM A480/A480M |

| Surface Finish | Appearance and texture | 2B, BA, No.4, HL, Mirror (No.8) | ASTM A480/A480M, EN 10088-2 |

| Tensile Strength (UTS) | Maximum stress before fracture | 515-620 MPa (304), 485-620 MPa (316) | ASTM A370 |

| Yield Strength (0.2% Offset) | Stress at which plastic deformation begins | 205-240 MPa (304), 170-240 MPa (316) | ASTM A370 |

| Elongation | Ductility, percentage of length increase before fracture | Min. 40% (304), Min. 40% (316) | ASTM A370 |

| Hardness | Resistance to indentation | Max 201 HB, Max 92 HRB (304/316) | ASTM E10, ASTM E18 |

| Edge Condition | Type of edge after slitting | Mill Edge, Slit Edge, Deburred Edge, Rolled Edge | Manufacturer's Specification |

Diverse Application Scenarios and Technical Advantages

The versatility of stainless steel strip coil makes it a preferred material across an extensive range of industries, delivering critical advantages in diverse environments. Its inherent properties, coupled with precise manufacturing, ensure reliability and longevity.

Target Industries:

- Petrochemical: For heat exchangers, chemical processing equipment, and pipelines where resistance to aggressive chemicals and high temperatures is paramount.

- Metallurgy: Components for high-temperature furnaces, industrial ovens, and material handling systems requiring robust and corrosion-resistant materials.

- Water Supply & Drainage: Piping, tanks, and treatment plant components benefiting from excellent corrosion resistance and hygiene properties.

- Automotive: Exhaust systems, trim components, fuel lines, and catalytic converters where durability, high temperature resistance, and aesthetic appeal are essential.

- Electronics: Precision stamping parts, connectors, and casings for consumer electronics and industrial control systems, requiring `precision stainless steel strip` for intricate designs.

- Medical Devices: Surgical instruments, implants, and hospital equipment due to its biocompatibility, sterilizability, and corrosion resistance.

- Construction & Architecture: Facades, roofing, and structural elements where longevity, low maintenance, and aesthetic finish are valued.

Demonstrated Advantages in Typical Application Scenarios:

- Corrosion Resistance: In marine environments or chemical processing plants, stainless steel, particularly grades like 316L, exhibits superior resistance to pitting and crevice corrosion, significantly extending the service life of equipment and reducing maintenance costs. This direct advantage translates into enhanced operational reliability and safety.

- Energy Saving: In heat exchanger applications, the smooth surface finish and thermal properties of stainless steel minimize fouling and allow for efficient heat transfer, leading to optimized energy consumption and reduced operational expenses over time.

- High Strength-to-Weight Ratio: For automotive components or aerospace applications, `stainless spring steel strip` allows for the design of lighter, yet robust structures, contributing to fuel efficiency and improved performance without compromising safety or integrity.

- Hygienic Properties: In food processing and pharmaceutical industries, the non-porous and easily cleanable surface of stainless steel prevents bacterial growth and contamination, adhering to stringent hygiene standards like FDA requirements. This directly impacts product quality and consumer safety.

- Durability and Low Maintenance: The inherent strength and resistance to degradation reduce the need for frequent replacements and maintenance, leading to lower lifecycle costs and sustained operational efficiency for infrastructure projects and long-term installations.

Vendor Comparison: Key Considerations for High-Quality Stainless Steel Strip Coil

Selecting the right supplier for stainless steel strip coil is a strategic decision that directly impacts product quality, operational efficiency, and cost-effectiveness. A thorough vendor comparison should extend beyond just price, focusing on capabilities, quality assurances, and support services.

| Factor | High-Performance Vendor | Standard Vendor (Potential Limitations) |

|---|---|---|

| Material Certifications | Comprehensive MTCs (Mill Test Certificates) traceable to international standards (ISO, ASTM, EN). Third-party inspections (e.g., SGS) readily available. | Basic certifications, potentially lacking detailed traceability or third-party validation. |

| Precision Capabilities | Ability to produce `precision stainless steel strip` with ultra-tight thickness and width tolerances (e.g., +/- 0.005mm thickness, +/- 0.05mm width). Advanced slitting and edge finishing options. | Standard tolerances, limited options for precision slitting or specialized edge treatments. |

| Surface Finish Quality | Consistent and defect-free finishes (e.g., superior BA, bright annealed, mirror finish), meeting specific roughness (Ra) requirements. | Variations in surface quality, potential for minor defects or inconsistencies. |

| Customization & R&D | Offers tailored solutions for specific alloy compositions, temper, or surface treatments. Strong R&D capabilities for new product development. | Primarily offers standard grades and sizes, limited flexibility for custom requests. |

| Lead Time & Logistics | Reliable and transparent lead times, efficient logistics network, flexible delivery options for global distribution. | Inconsistent lead times, limited shipping options, potential for delays. |

| Technical Support & After-sales | Dedicated technical experts, readily available after-sales support, robust warranty, and complaint resolution processes. | Limited technical guidance, slow or inadequate after-sales support. |

Our company prides itself on embodying the characteristics of a high-performance vendor, with over 15 years of experience in the industry, ISO 9001 and CE certifications, and a proven track record of serving major clients in petrochemical and automotive sectors. Our commitment to quality ensures that every `high quality stainless steel strip roll` leaving our stainless steel strip factory meets or exceeds global benchmarks.

Customized Solutions for Unique Industrial Demands

Recognizing that off-the-shelf solutions may not always suffice for complex industrial challenges, we specialize in providing highly customized stainless steel strip coil products. Our engineering team collaborates closely with clients to develop tailored specifications that precisely match application requirements.

- Alloy Composition Adjustments: Modifying the chemical composition to enhance specific properties such as elevated temperature strength, improved pitting resistance, or specific magnetic permeability.

- Temper and Hardness Control: Achieving specific temper conditions, from fully annealed (soft) to various levels of temper rolling (e.g., full hard, quarter hard), crucial for applications like `stainless spring steel strip` where spring-back and formability are critical.

- Precision Dimensional Tolerances: Supplying strips with exceptionally tight tolerances on thickness, width, and flatness, essential for high-precision stamping, deep drawing, and automated assembly lines.

- Specialized Surface Finishes: Beyond standard finishes, we offer custom surface treatments like specific grit polishing, brushing, or specialized coatings to meet aesthetic, functional, or hygienic demands.

- Edge Conditioning: Custom edge profiles, including deburred, rounded, or custom-shaped edges, to facilitate smooth processing and enhance product safety.

- Coil Configuration: Tailored coil weights, inner and outer diameters, and winding tensions to integrate seamlessly into client production lines, optimizing efficiency and minimizing downtime.

Our state-of-the-art R&D facilities and experienced metallurgists are equipped to address even the most challenging material specifications, ensuring that the final product not only meets but often exceeds performance expectations. This bespoke approach minimizes waste, optimizes manufacturing processes for our clients, and fosters long-term, trusted partnerships.

Real-World Application Case Studies

Case Study 1: High-Performance Automotive Exhaust Systems

A leading automotive manufacturer approached us with a requirement for a specialized stainless steel strip coil for high-temperature exhaust system components. The material needed exceptional resistance to oxidation and corrosion at sustained temperatures exceeding 800°C, combined with superior formability for intricate designs. We collaborated to supply a customized 409L stainless steel strip with a specific temper and surface finish. Our material demonstrated superior performance in accelerated corrosion tests, extending the component's lifespan by 30% compared to previous suppliers' materials. This resulted in reduced warranty claims for the client and enhanced brand reputation for durability. The precision of our `stainless steel strip factory` output ensured seamless integration into their automated stamping lines, leading to higher production yields.

Case Study 2: Medical Device Components Requiring Ultra-Precision

A manufacturer of critical medical implants required a `precision stainless steel strip` with extremely tight thickness tolerances (±0.005 mm) and a super-smooth, defect-free surface (Ra

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity (MOQ) for stainless steel strip coil?

A1: Our MOQ varies depending on the specific grade, thickness, width, and customization required. For standard grades and sizes, it typically ranges from 1 to 5 metric tons. For highly specialized or `precision stainless steel strip` products, please contact our sales team for a detailed consultation.

Q2: Can you provide Mill Test Certificates (MTCs) and other quality documentation?

A2: Absolutely. Every shipment of our `high quality stainless steel strip roll` is accompanied by comprehensive MTCs, traceable to international standards (e.g., EN 10204 3.1 or 3.2). We also provide certifications for ISO 9001:2015, ISO 14001:2015, and other relevant industry standards as required.

Q3: What are the typical lead times for your products?

A3: Lead times depend on product specifications, quantity, and current production schedules. For standard items, it typically ranges from 3 to 6 weeks. For customized orders, lead times can be 6 to 10 weeks. We always strive to meet urgent delivery requirements and will provide a precise lead time upon order confirmation.

Q4: Do you offer samples for testing before a large order?

A4: Yes, we understand the importance of material validation. We can provide samples of our stainless steel strip coil for preliminary testing, subject to material availability and agreed-upon terms. Please contact our sales team with your specific requirements.

Lead Time & Fulfillment

Our streamlined production processes and robust supply chain management ensure efficient order fulfillment. For standard `stainless steel strip factory` products, we aim for a lead time of 3-6 weeks from order confirmation to shipment. For custom specifications or larger volumes, lead times may extend to 6-10 weeks. We maintain transparent communication throughout the order lifecycle, providing regular updates on production status and estimated delivery dates. Our global logistics partners facilitate reliable and timely delivery worldwide, ensuring your stainless steel strip coil arrives precisely when and where you need it.

Warranty Commitments

We stand behind the quality of our stainless steel strip coil with a comprehensive warranty against manufacturing defects and material non-conformity to agreed specifications. Our warranty period typically covers 12 months from the date of shipment, ensuring peace of mind for our clients. In the unlikely event of a material defect, we commit to swift investigation, analysis, and appropriate resolution, including replacement or credit, in accordance with our terms and conditions. This commitment is a cornerstone of our customer trust and product reliability.

Dedicated Customer Support

Our commitment to our clients extends far beyond product delivery. We offer dedicated customer support services, including technical consultation, application engineering assistance, and after-sales service. Our team of experienced professionals is available to answer inquiries, provide guidance on material selection, and troubleshoot any challenges you may encounter. For support, please reach out to our team via phone at [Insert Phone Number] or email at [Insert Email Address]. Our goal is to build enduring partnerships based on superior product quality and unparalleled customer service.

Conclusion

The journey from raw ore to a highly specialized stainless steel strip coil is a testament to advanced metallurgical science and precision engineering. As industries evolve, the demand for materials that offer superior performance, durability, and customization continues to grow. Our commitment as a premier `stainless steel strip factory` is to not only meet these evolving demands but to exceed them through continuous innovation, rigorous quality control, and an unwavering focus on customer satisfaction. Partnering with us ensures access to `high quality stainless steel strip roll` products backed by extensive expertise, proven experience, and uncompromising trustworthiness.

References

- American Society for Testing and Materials (ASTM). ASTM A240/A240M: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

- European Committee for Standardization (CEN). EN 10088-2: Stainless steels - Part 2: Technical delivery conditions for sheet, plate and strip of corrosion resisting steels for general purposes.

- International Organization for Standardization (ISO). ISO 9001:2015: Quality management systems – Requirements.

- International Organization for Standardization (ISO). ISO 14001:2015: Environmental management systems – Requirements with guidance for use.

- Outokumpu. Handbook of Stainless Steel. Outokumpu Stainless Steel, 2013.

- ASM International. ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International, 1990.

This is the last article

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025