- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dez . 25, 2024 20:40 Back to list

automotive ac hose clamps factory

The Importance of Quality in Automotive AC Hose Clamps A Focus on Manufacturing

In the automotive industry, the efficiency of air conditioning systems plays a crucial role in vehicle performance and passenger comfort. One of the unsung heroes of AC systems is the hose clamp. While often overlooked, the quality of automotive AC hose clamps is imperative for the integrity and efficiency of the cooling system. This article delves into the significance of these clamps, the manufacturing process, and what to look for when sourcing them from a factory.

Understanding the Role of AC Hose Clamps

Automotive AC hose clamps are designed to securely attach hoses that transport refrigerant from the compressor to the condenser and evaporator. These clamps ensure that the hoses are properly sealed, preventing leaks of refrigerant, which can not only diminish cooling performance but also create environmental hazards. A high-quality hose clamp can prevent issues such as refrigerant loss, which affects not only the air conditioning efficiency but also the overall functionality and longevity of the system.

Manufacturing of AC Hose Clamps

The manufacturing process of automotive AC hose clamps involves several critical steps to ensure durability and performance.

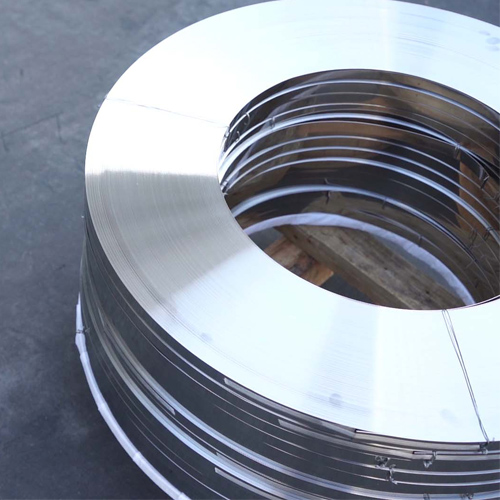

1. Material Selection The first step in producing high-quality hose clamps is the selection of raw materials. Stainless steel is typically preferred for its resistance to corrosion and high temperature, especially given that the operating conditions in car engines and AC systems can be extreme. Some manufacturers may also offer clamps made from other materials, but stainless steel remains the industry standard.

2. Design and Engineering Next, the designs are created with specific requirements in mind. Hose clamps must be capable of adjusting to various hose diameters while providing sufficient clamping force. Advanced engineering techniques are employed to create designs that facilitate ease of installation and removal, providing versatility for different make and model vehicles.

3. Manufacturing Process The clamps are produced using methods such as stamping, welding, and heat treatment. Stamping molds create the basic shape, while welding processes join segments of the clamp. Heat treatment can enhance the material properties, providing increased strength and durability. Each manufacturing step requires precise controls to maintain quality and consistency.

4. Quality Control Quality assurance is a critical aspect of manufacturing automotive AC hose clamps. Each batch undergoes rigorous testing to ensure that it meets industry standards. Tests may include inspections for tensile strength, corrosion resistance, and dimensional accuracy. Factories implementing ISO and TS certifications showcase their commitment to quality through systematic checks.

automotive ac hose clamps factory

5. Finishing Touches Finally, clamps may receive surface treatments such as galvanization or plating to enhance their resistance to corrosion and wear. This finishing not only adds to the aesthetic appeal but also contributes to longevity in harsh operating conditions.

Choosing the Right Factory

When sourcing automotive AC hose clamps from a factory, several factors should be considered to ensure the best quality

- Certification and Compliance Check if the factory meets international quality standards such as ISO 9001. Compliance with automotive industry standards is crucial for reliability and safety.

- Experience and Expertise Choose a factory with substantial experience in manufacturing automotive components. Experienced manufacturers are more likely to have refined their processes to ensure high-quality output.

- Research and Development A factory that invests in R&D is likely to stay ahead of market trends and needs, providing innovative solutions that enhance product performance.

- Customer Reviews and Feedback Research customer testimonials and reviews. A manufacturer with a positive reputation in the industry will be more reliable in terms of quality and service.

Conclusion

Automotive AC hose clamps may seem like minor components, but they play a significant role in the functionality and reliability of a vehicle's air conditioning system. By emphasizing quality in the manufacturing process, factories can produce hose clamps that not only meet but exceed industry standards. For automotive manufacturers and repair shops, understanding the importance of these components and sourcing them from reputable factories can greatly enhance the performance and longevity of vehicle air conditioning systems.

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025

-

Mini Hose Clamp Manufacturer & Supplier Precision Hose Clamps Mini Clamp Factory

NewsJul.07,2025