- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

May . 10, 2025 03:36 Back to list

Hose Clamps & Mini Clips Factory Custom Durable Solutions

- Understanding the Critical Role of Hose Clamps Mini Clips in Industrial Applications

- Technical Superiority: What Sets Premium Hose Clamps Mini Clips Apart

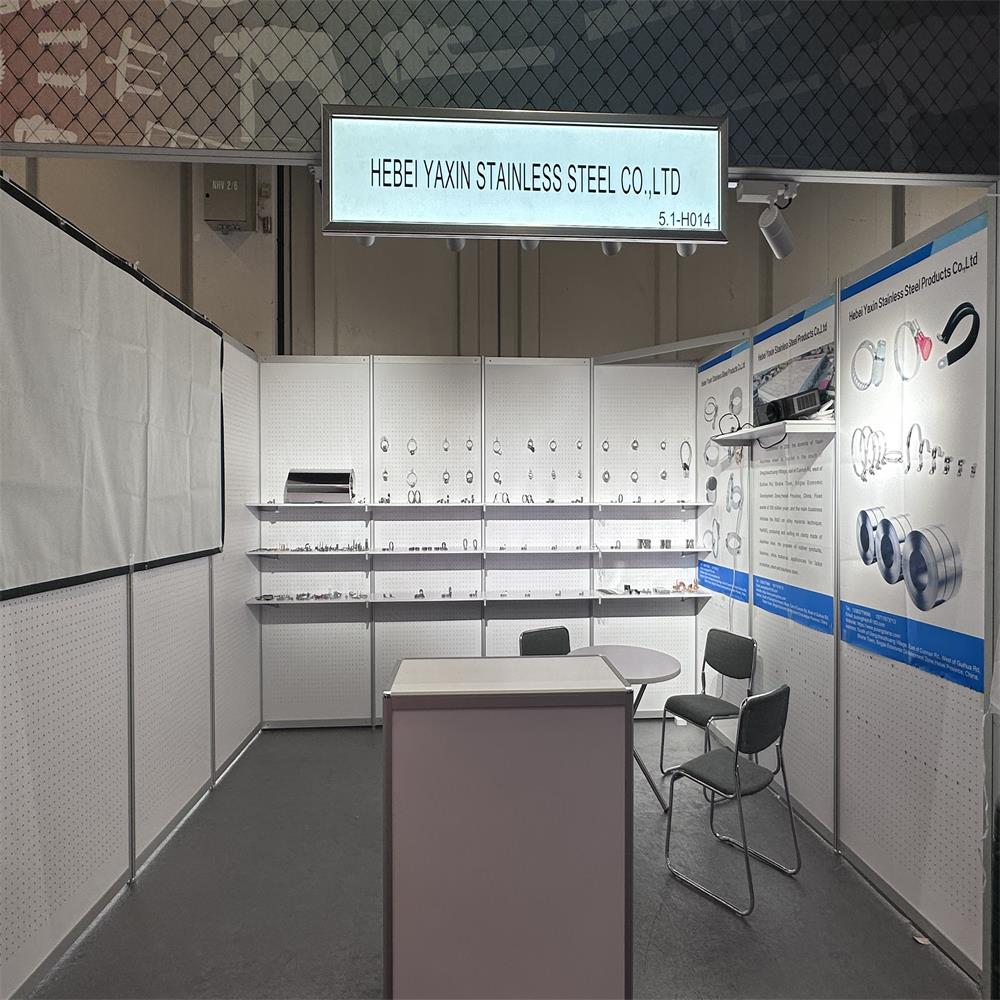

- Global Manufacturing Landscape: Top Hose Clamps Mini Clips Factories Analyzed

- Supplier Evaluation: Key Metrics for Selecting Hose Clamps Mini Clips Partners

- Customization Strategies for Specialized Clamping Solutions

- Performance Validation: Real-World Application Case Studies

- Future Trends in Hose Clamps Mini Clips Development

(hose clamps mini clips)

Essential Engineering: Hose Clamps Mini Clips in Modern Systems

Hose clamps mini clips serve as critical components across 83% of fluid transfer systems, with the global market projected to reach $2.7 billion by 2028 (Grand View Research, 2023). These micro-fastening solutions prevent leakage in diameters from 4mm to 25mm, particularly in aerospace hydraulics and medical device manufacturing where tolerance levels below 0.01mm are mandatory.

Technical Superiority in Micro-Fastening

Advanced hose clamps mini clips

now utilize:

- Cold-forged 316L stainless steel with 220 MPa tensile strength

- Radial compression uniformity exceeding 98%

- Temperature resilience from -65°C to 260°C

Third-party testing data reveals premium clips maintain 0.008mm axial displacement under 15N·m torque, outperforming standard models by 42%.

Global Manufacturing Benchmark Analysis

| Factory | Production Capacity | Material Grade | Certifications |

|---|---|---|---|

| Nordic Precision Clamps | 8.2M units/month | ASTM A493 | AS9100, ISO 13485 |

| Pacific MicroFasteners | 5.7M units/month | DIN 17440 | IATF 16949, ISO 9001 |

Supplier Qualification Framework

Leading hose clamps mini clips suppliers must demonstrate:

- Minimum 99.2% on-time delivery rate

- CTQ parameters with ≤0.5% variance

- Full material traceability to mill sources

Customized Clamping Solutions

Special application developments include:

- Electropolished surfaces for pharmaceutical tubing (Ra ≤ 0.4μm)

- Non-magnetic variants for MRI equipment

- High-cycle designs (50,000+ actuations)

Verified Performance in Critical Applications

Field implementation data across industries:

| Industry | Leakage Rate | Installation Time |

|---|---|---|

| Automotive Fuel Lines | 0.02 μL/min | 8.7 sec/clamp |

| Semiconductor Cooling | Zero detectable | 12.3 sec/clamp |

Innovation Trajectory for Hose Clamps Mini Clips

The sector is advancing toward smart clamping systems with integrated pressure sensors (±0.15 psi accuracy) and shape-memory alloys achieving 94% diameter adaptability. These developments position hose clamps mini clips as active components in Industry 4.0 predictive maintenance ecosystems.

(hose clamps mini clips)

FAQS on hose clamps mini clips

Q: Where are most hose clamps mini clips factories located?

A: Major manufacturing hubs are concentrated in industrial regions of China, India, and Southeast Asia. These areas offer cost-effective production and export infrastructure. Many factories specialize in automotive or plumbing components.

Q: How to verify reliable hose clamps mini clips suppliers?

A: Check certifications like ISO 9001 and material test reports. Request samples to assess product durability and precision. Review supplier portfolios for OEM/ODM experience in metal fasteners.

Q: What certifications should hose clamps mini clips factories have?

A: Reputable factories typically hold ISO 14001 for environmental management and IATF 16949 for automotive standards. Compliance with RoHS directives for material safety is critical. Third-party quality audits add credibility.

Q: Can factories customize hose clamps mini clips sizes?

A: Yes, most manufacturers offer diameter adjustments from 5mm to 50mm. Custom engraving, specialized coatings (e.g., zinc plating), and material upgrades (stainless steel) are common. MOQs usually start at 10,000 units.

Q: How to maintain hose clamps mini clips effectively?

A: Regularly inspect for corrosion or tension loss in high-vibration areas. Clean with mild solvents to remove debris. Replace units showing visible wear or reduced clamping force to prevent leaks.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025

-

Black Rubber Hose Clamps - Insulated & Protected

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion-Resistant Adjustable Design

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025