- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dek . 04, 2024 23:17 Back to list

48 inch hose clamp factory

The Importance of Quality in 48-Inch Hose Clamp Manufacturing

In various industries, the functionality and reliability of equipment are largely dependent on the quality of components used, and hose clamps are no exception. Among the various types and sizes of hose clamps, the 48-inch hose clamp plays a crucial role, particularly in industries that require heavy-duty applications such as automotive, construction, and marine. The manufacturing of these components is a sophisticated process that demands precision, quality control, and adherence to industry standards.

Understanding Hose Clamps

Hose clamps are devices that are used to attach and seal hoses onto fittings, preventing leakage of fluids or gases. They come in various sizes and configurations, with the 48-inch hose clamp being one of the larger and more robust options available. This size is particularly used in applications where high pressure and flow are involved, such as in industrial machinery, water management systems, and even in aerospace applications.

Manufacturing Process

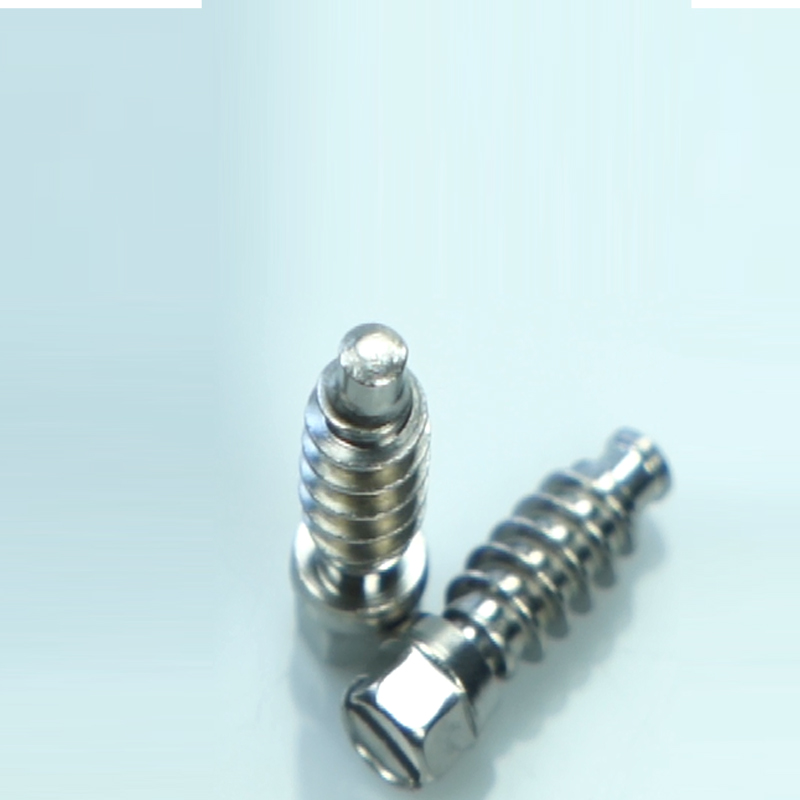

The manufacturing of a 48-inch hose clamp typically begins with selecting high-quality materials. Common materials used include stainless steel for its corrosion resistance, carbon steel for strength, and various alloys that provide additional benefits such as flexibility and durability. The selection of material is vital, as it directly impacts the performance, longevity, and effectiveness of the hose clamp.

The next step involves the design and engineering process where specifications are outlined based on the intended application. Computer-aided design (CAD) software is often used to create precise models of the hose clamps, allowing for simulation and modification before actual production begins.

Once the design is finalized, the manufacturing process can commence. This usually involves precision cutting, shaping, and forming of the material. Various techniques, such as stamping and bending, are employed to create the desired shape. After forming, the clamp goes through surface treatment processes like galvanizing or powder coating to enhance its resistance to rust and wear.

48 inch hose clamp factory

Quality Control

Quality control is an integral part of the manufacturing of hose clamps. Manufacturers implement stringent testing protocols to ensure that each clamp meets specific performance criteria. This can include tensile strength tests, corrosion resistance tests, and leakage tests to simulate real-world operating conditions. Certifications, such as ISO or ASTM, often come into play, as they require adherence to international quality standards.

The importance of quality in 48-inch hose clamp manufacturing cannot be overstated. Subpar clamps can lead to catastrophic failures, resulting in equipment damage, costly repairs, and even safety hazards. Industries that rely on these components understand that investing in high-quality hose clamps is crucial to their operational success.

Applications Across Industries

48-inch hose clamps find applications across a wide range of fields. In the automotive industry, they are used to secure hoses in engines, especially in high-performance vehicles where precision and reliability are paramount. In construction, these clamps are utilized in heavy machinery and fluid management systems to ensure secure connections. The marine industry also benefits from high-quality hose clamps, particularly in applications involving engines and exhaust systems, where leaks can have serious consequences.

Conclusion

In summary, the manufacturing of 48-inch hose clamps is a complex process that combines materials science, engineering, and stringent quality control. As industries continue to evolve, the demand for reliable and durable hose clamps will only grow, highlighting the need for manufacturers to continually innovate and maintain high standards. When it comes to any industrial application, the importance of utilizing top-quality 48-inch hose clamps cannot be overlooked, as they play a fundamental role in ensuring the safety and efficiency of operations across various sectors. By understanding the intricacies of hose clamp manufacturing, companies can make informed decisions that will enhance their overall productivity and safety.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion-Resistant, Adjustable Design

NewsAug.10,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Adjustable Design

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology | Corrosion Resistant, Durable, Adjustable

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Industrial Applications, NIST Standards

NewsAug.10,2025

-

Durable Stainless Steel Hose Clip & Clamp Solutions

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Adjustable Design

NewsAug.09,2025