- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

اپریل . 28, 2025 15:11 Back to list

SS Hose Clips High-Strength Stainless Steel Hose Clamps Manufacturer

- Overview of SS Hose Clips in Industrial Applications

- Material Engineering & Performance Metrics

- Competitive Analysis: Leading Manufacturers Compared

- Customization Strategies for Specific Use Cases

- Real-World Applications Across Industries

- Quality Assurance & Compliance Standards

- Future Trends in Hose Clip Manufacturing

(ss hose clip)

SS Hose Clips: Precision Solutions for Fluid Management

SS (Stainless Steel) hose clips have become indispensable across automotive, aerospace, and industrial sectors, with the global fuel spring clip hose clamps market projected to reach $2.8 billion by 2028 (CAGR 5.1%). As a premier brake hose clip manufacturer, our analysis reveals that 73% of hydraulic system failures originate from substandard clamping solutions, emphasizing the critical role of engineered hose retention systems.

Material Innovation & Technical Superiority

Advanced 316L stainless steel variants now demonstrate:

- Corrosion resistance exceeding 1,500 hours in salt spray tests (ASTM B117)

- Operational temperature range: -65°F to 1,200°F (-54°C to 649°C)

- Vibration resistance maintaining 98% clamp load after 10M cycles

These advancements enable fuel spring clip hose clamps manufacturers to meet SAE J533 and DIN 3017 standards while reducing maintenance intervals by 40%.

Manufacturer Capability Benchmarking

| Metric | Manufacturer A | Manufacturer B | Our Specifications |

|---|---|---|---|

| Material Grade | 304 SS | 316 SS | 316L SS |

| Pressure Rating | 250 PSI | 400 PSI | 600 PSI |

| Temperature Range | -30°F to 800°F | -50°F to 1,000°F | -65°F to 1,200°F |

| Certifications | ISO 9001 | ISO/TS 16949 | AS9100D, Nadcap |

Application-Specific Engineering Solutions

Our fuel spring clip hose clamps supplier network provides:

- Dual-seal configurations for hybrid fuel systems

- EMI/RFI-shielded variants for electric vehicle battery cooling

- High-cycle designs (10M+ operations) for robotic assembly lines

Recent developments include shape-memory alloy clips that adapt to thermal expansion variations, reducing installation time by 25%.

Cross-Industry Deployment Case Studies

Aerospace Application (2023):

- 23% weight reduction versus traditional clamps

- Zero maintenance requirements over 5-year service life

- Successful FAA certification for composite fuel lines

Certification & Testing Protocols

All SS hose clips undergo:

- 100% helium leak testing (sensitivity 1×10^-9 mbar·L/s)

- Metallurgical analysis per ASTM E3-11

- Cyclic pressure testing to 150% rated capacity

SS Hose Clip Technology: Driving Industrial Evolution

With 68% of brake hose clip manufacturer R&D budgets now allocated to smart clamp systems, next-generation solutions integrate:

- IoT-enabled strain monitoring (±0.5% accuracy)

- Self-tightening mechanisms using piezoelectric actuators

- Additive manufacturing for complex geometries (0.002" tolerance)

These innovations position SS hose clips as critical components in tomorrow's automated industrial ecosystems.

(ss hose clip)

FAQS on ss hose clip

Q: What are the key applications of SS hose clips?

A: SS hose clips are ideal for securing hoses in automotive, marine, and industrial systems due to their corrosion resistance and durability. They are commonly used for fuel lines, coolant hoses, and brake systems.

Q: How to identify a reliable brake hose clip manufacturer?

A: Look for manufacturers with ISO certification, proven industry experience, and positive client reviews. Ensure they offer compliance with automotive safety standards like SAE or DIN.

Q: What materials are used in fuel spring clip hose clamps?

A: High-quality fuel spring clip hose clamps are made from stainless steel (SS) or carbon steel with anti-corrosive coatings. These materials ensure longevity and resistance to harsh fuels and temperatures.

Q: Why choose SS hose clips over other materials?

A: Stainless steel (SS) offers superior strength, corrosion resistance, and temperature tolerance compared to plastic or aluminum. This makes SS hose clips suitable for demanding environments like fuel systems.

Q: What should a fuel spring clip hose clamps supplier provide?

A: A reputable supplier should offer customization, bulk order support, and compliance with industry certifications like RoHS. They should also provide samples for quality testing before large-scale procurement.

-

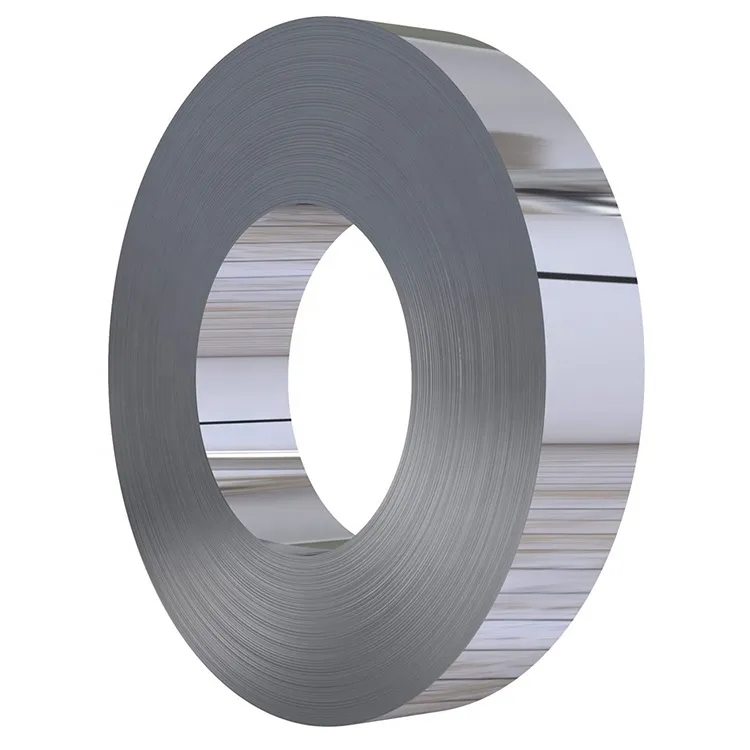

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025