- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

نويابىر . 11, 2024 11:46 Back to list

suction hose clamps

Understanding Suction Hose Clamps Importance, Types, and Applications

In various industrial and commercial applications, especially those involving fluid transfer, suction hose clamps play a critical role in maintaining system integrity and performance. This article aims to explore the significance, types, and applications of suction hose clamps, providing insights relevant to engineers, technicians, and anyone involved in fluid handling operations.

What are Suction Hose Clamps?

Suction hose clamps are mechanical devices designed to secure hoses, especially those used in suction and discharge applications. These clamps ensure that hoses remain tightly connected to couplings, preventing leaks and maintaining consistent flow rates. The importance of these clamps cannot be overstated, as even minor leaks can lead to significant operational inefficiencies, safety hazards, and increased costs.

The Importance of Suction Hose Clamps

1. Leak Prevention One of the primary functions of suction hose clamps is to prevent leaks. Fluid leaks can not only result in product loss but can also lead to hazardous situations, especially when dealing with toxic or corrosive substances. Properly secured hoses minimize the risk of spills and ensure a cleaner, safer work environment.

2. Pressure Maintenance By ensuring a tight connection between the hose and fittings, suction hose clamps help maintain the required pressure within the system. This is particularly crucial in applications where precise fluid transfer is essential, such as in pumping systems and chemical processing.

3. Durability and Longevity High-quality clamps can enhance the overall durability of the hose assembly. They can withstand a range of environmental conditions, including temperature fluctuations and exposure to chemicals, thus prolonging the life of the hoses and reducing the need for frequent replacements.

Types of Suction Hose Clamps

There are several types of suction hose clamps available, each designed for specific applications and hose types

1. Spring Clamps These clamps use spring tension to maintain a tight grip on the hose. They are especially useful in applications where flexibility is needed, as they can adjust to minor changes in hose diameter without losing grip.

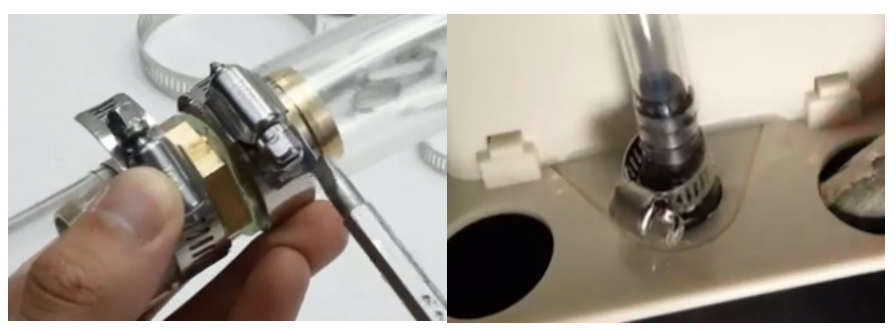

2. Worm Gear Clamps These clamps feature a metal band with a screw mechanism. They are commonly used for their ability to provide a strong and adjustable hold on various hose sizes. The screw mechanism allows for easy tightening and loosening as needed.

suction hose clamps

3. Constant-Tension Clamps Designed to maintain a consistent level of pressure on the hose throughout its lifecycle, these clamps automatically adjust to changes in temperature and hose diameter, making them ideal for environments with fluctuating conditions.

4. Butt Weld Clamps These are specific to industries where hoses are welded instead of connected with fittings. They provide a secure hold and are often used in steam and high-pressure applications.

Applications of Suction Hose Clamps

Suction hose clamps are versatile and can be found in various industries, including

- Agriculture They are commonly used in irrigation systems and machinery that transfers water or other liquids.

- Chemical Processing Due to their leak prevention capabilities, these clamps are critical in facilities that handle corrosive or hazardous materials.

- Construction Suction hose clamps are used in pumping operations on construction sites to manage water and other fluids effectively.

- Automotive In vehicle manufacturing and maintenance, they secure fuel and brake line hoses, ensuring safety and performance.

- Food and Beverage Industry Sanitary suction hose clamps are essential in processing plants to maintain hygiene while handling liquids.

Conclusion

Suction hose clamps are a vital component in many fluid transfer systems across various industries. Their ability to prevent leaks, maintain pressure, and enhance durability contributes significantly to operational efficiency and safety. By understanding the different types of clamps available and their applications, professionals can make informed decisions about which products to use for specific needs, ensuring optimal performance and reliability in their operations. Proper selection and maintenance of suction hose clamps can lead to reduced downtime, lower costs, and improved safety, making them a crucial element in any fluid handling system.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Adjustable Design

NewsAug.16,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.16,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion-Resistant&Adjustable Design

NewsAug.16,2025

-

High Quality Stainless Steel Strip Roll | 301 & 316 Precision

NewsAug.16,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.15,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy|Durable Stainless Steel Construction&Adjustable Design

NewsAug.15,2025