- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

نويابىر . 06, 2024 17:58 Back to list

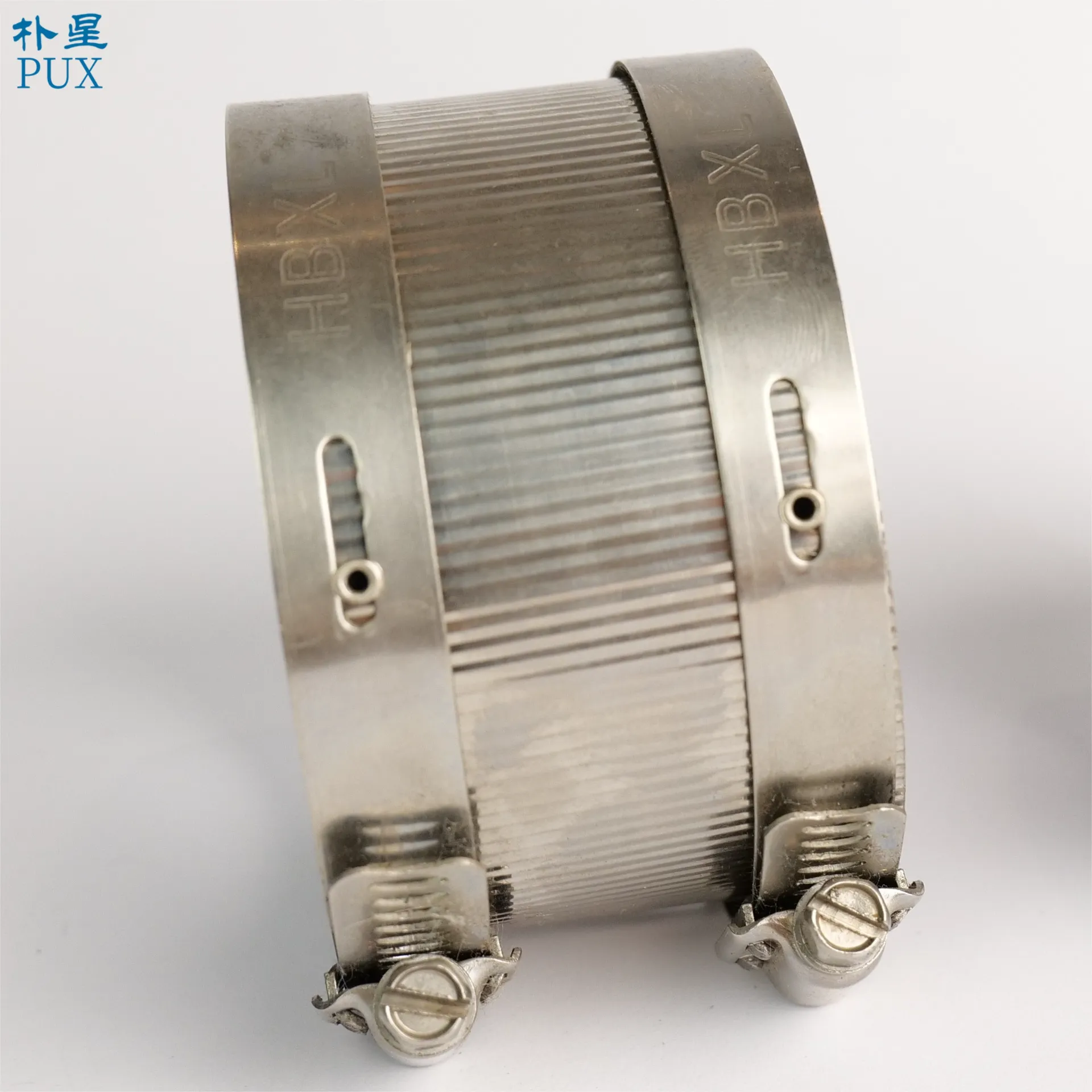

Hose Clamp Holder Production Solutions by Leading Manufacturers in the Industry

The Importance of Hose Clamp Holders A Comprehensive Guide for Manufacturers

In the world of manufacturing, especially in industries that involve fluid transfer, the significance of reliable and durable hose clamp holders cannot be overstated. These seemingly simple components play a crucial role in ensuring that hoses remain secure, preventing leaks and maintaining system efficiency. This article delves into the essentials of hose clamp holders, discussing their types, materials, applications, and the role of manufacturers in this specialized market.

Understanding Hose Clamp Holders

Hose clamp holders are essential fastening devices that secure hoses to fittings, ensuring a tight and leak-proof connection. They come in various shapes and sizes, tailored to accommodate different hose diameters and types. The effectiveness of hose clamps directly impacts the performance of fluid systems, which can range from automotive applications to industrial processes.

Types of Hose Clamp Holders

1. Worm Gear Clamps One of the most popular types, worm gear clamps consist of a steel band tightened by a screw mechanism. They are versatile and can be adjusted for different hose diameters, making them suitable for a wide range of applications.

2. Spring Clamps These clamps use a spring mechanism to maintain tension on the hose. They are easy to install and remove, making them a preferred choice for applications requiring frequent maintenance.

3. Heavy-Duty Clamps Designed for high-pressure applications, heavy-duty clamps are made from robust materials and often feature additional reinforcement. These clamps ensure that hoses remain securely attached even under extreme conditions.

4. Specialized Clamps Manufacturers often cater to specific industries with specialized clamps. These can include clamps resistant to certain chemicals, high temperatures, or unique shapes to fit unconventional hose designs.

Materials Used in Hose Clamp Holders

The choice of materials is pivotal in the manufacturing of hose clamp holders. Commonly used materials include

- Stainless Steel Known for its corrosion resistance and strength, stainless steel is ideal for applications exposed to moisture, chemicals, or extreme temperatures.

hose clamp holder manufacturer

- Plastic Plastic clamps are lightweight and resistant to corrosion, making them suitable for applications where weight is a concern

. However, they may not withstand high pressures as effectively as metal counterparts.- Zinc-Plated Steel For cost-effective solutions, manufacturers often use zinc-plated steel. While it offers good protection against corrosion, it may not be suitable for all environments.

Applications of Hose Clamp Holders

Hose clamp holders find applications across various industries, including automotive, aerospace, marine, and plumbing. In the automotive sector, they secure hoses in engines, fuel systems, and cooling systems. In the aerospace industry, they help maintain the integrity of hydraulic systems. Each application comes with its unique set of challenges, and manufacturers must ensure that their products meet stringent industry standards.

The Role of Manufacturers

As a hose clamp holder manufacturer, several factors must be considered to create quality products

1. Quality Control Implementing rigorous quality control measures is essential. Products should be tested for strength, durability, and resistance to environmental factors.

2. Custom Solutions Many industries require custom clamps tailored to specific applications. Manufacturers should be willing to collaborate with clients to develop bespoke solutions.

3. Sustainability As industries become more environmentally conscious, manufacturers should consider eco-friendly materials and processes in their production lines.

4. Innovation The market is evolving, and staying ahead of the competition requires continuous innovation. This can include developing new materials or designs that enhance performance and ease of installation.

Conclusion

Hose clamp holders might seem like minor components in larger systems, but their role is integral to operational success and safety across various industries. As a manufacturer, understanding the requirements of these products, including their materials, types, and applications, lays the foundation for producing reliable and effective hose clamp holders. Commitment to quality, customization, and innovation will ensure that manufacturers can meet the demands of an ever-evolving market, ultimately contributing to the overall efficiency and safety of fluid systems worldwide. In an industry where precision is key, the importance of hose clamp holders remains indisputable.

-

High Quality Steel Midsoles in EN Standard | Safety Footwear

NewsJul.22,2025

-

Premium Cold Rolled Stainless Steel Strips | High Precision & Smooth

NewsJul.21,2025

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025