- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

دېكابىر . 04, 2024 05:59 Back to list

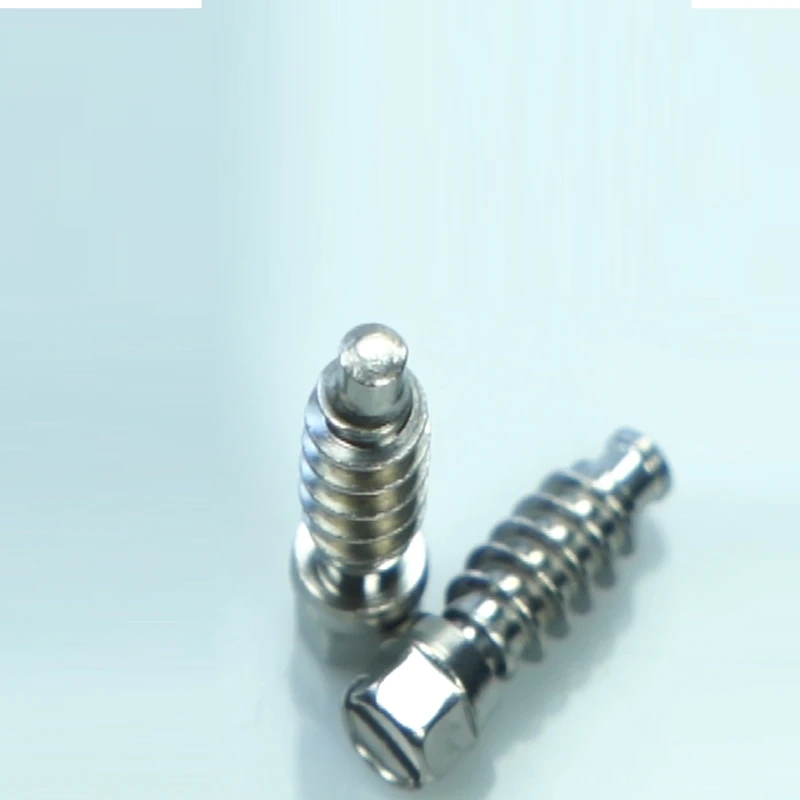

High-Performance Fuel Injection Hose Clamp Production for Automotive Applications

High Pressure Fuel Injection Hose Clamp Manufacturer Ensuring Safety and Efficiency in Automotive Applications

In the world of automotive engineering, precision and safety are paramount. High pressure fuel injection systems play a crucial role in modern vehicles, enabling efficient fuel delivery and optimizing engine performance. A key component in this system is the high pressure fuel injection hose clamp, which ensures the integrity and reliability of fuel lines under extreme conditions. Consequently, selecting a reputable high pressure fuel injection hose clamp manufacturer is vital for both performance and safety.

Understanding High Pressure Fuel Injection Systems

High pressure fuel injection systems have revolutionized the automotive industry. Unlike traditional carbureted engines, fuel injection systems atomize fuel, allowing for a more homogeneous mixture with air. This leads to better combustion, reduced emissions, and enhanced fuel efficiency. However, the high pressures involved—often exceeding 30,000 psi—require robust hardware that can withstand intense conditions. Low-quality components can lead to catastrophic failures, resulting in safety hazards and costly repairs.

The Role of Hose Clamps in Fuel Injection Systems

Hose clamps might appear to be simple components, but they play a critical role in maintaining the integrity of high pressure fuel lines. A high pressure fuel injection hose clamp's primary function is to secure flexible fuel hoses to their fittings, preventing leaks that could threaten engine performance or, worse, lead to dangerous fuel spills and fires. They must be capable of withstanding high pressure, temperature fluctuations, and exposure to fuel, making material choice and design particularly important.

Choosing a High Pressure Fuel Injection Hose Clamp Manufacturer

When selecting a manufacturer for high pressure fuel injection hose clamps, several factors come into play

1. Quality Standards Choose a manufacturer that adheres to stringent quality control measures. ISO certification and compliance with regulatory standards ensure that the clamps meet or exceed industry requirements.

high pressure fuel injection hose clamp manufacturer

2. Material Selection The materials used in hose clamps significantly affect their performance. High-quality stainless steel, for instance, offers excellent resistance to corrosion and is durable enough to handle high-pressure applications. Additionally, some manufacturers provide options for rubber or silicone lining, improving grip and seal integrity.

3. Design and Engineering Innovative design is essential for effective performance. A manufacturer that invests in research and development can offer clamps that provide better retention, increased pressure tolerance, and user-friendly features like ease of installation and removal.

4. Customization Options Different automotive applications may require unique specifications. A manufacturer that offers customization options can produce tailored solutions to meet specific demands, enhancing overall system performance.

5. Reputation and Experience A proven track record in the industry is a good indicator of a reliable manufacturer. Companies with years of experience and positive reviews are more likely to deliver quality products and dependable service.

6. Technical Support An excellent manufacturer should offer technical support and guidance. This includes knowledgeable staff who can assist with installation queries or troubleshoot potential issues.

The Impact of Quality Hose Clamps on Performance and Safety

Investing in high quality high pressure fuel injection hose clamps is not just about ensuring optimal performance; it is also about prioritizing safety. Leaks at high pressure can lead to fire hazards, threatening lives and property. A trustworthy manufacturer provides products that not only enhance the functionality of fuel systems but also bolster the overall safety of the vehicle.

In conclusion, the importance of selecting a reputable high pressure fuel injection hose clamp manufacturer cannot be overstated. Ensuring the use of high-quality components will safeguard fuel systems against leaks and failures, ultimately leading to safer and more efficient automotive operations. As the automotive industry continues to evolve, manufacturers who prioritize quality and innovation in their products will be the ones driving the future.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.12,2025

-

Precision Stainless Steel Strip Roll & Coil Manufacturer

NewsAug.12,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025

-

Black Rubber Hose Clamps - Insulated & Protected

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.11,2025