- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ئۆكتەبىر . 11, 2024 02:09 Back to list

3 8 hose clamp manufacturer

The Importance of Quality Hose Clamps A Look at 3 8% Hose Clamp Manufacturers

Hose clamps are an essential component in a variety of industries, ranging from automotive to plumbing, and even in aerospace applications. They are part of the fastening systems that secure hoses in place, preventing leaks and ensuring the efficient operation of machines and systems that utilize fluid transport. The significance of hose clamps cannot be overstated, especially when considering their role in maintaining the integrity of critical applications. Among numerous manufacturers in the market, the 3 8% hose clamp manufacturers have gained attention for their quality and reliability.

Understanding Hose Clamps

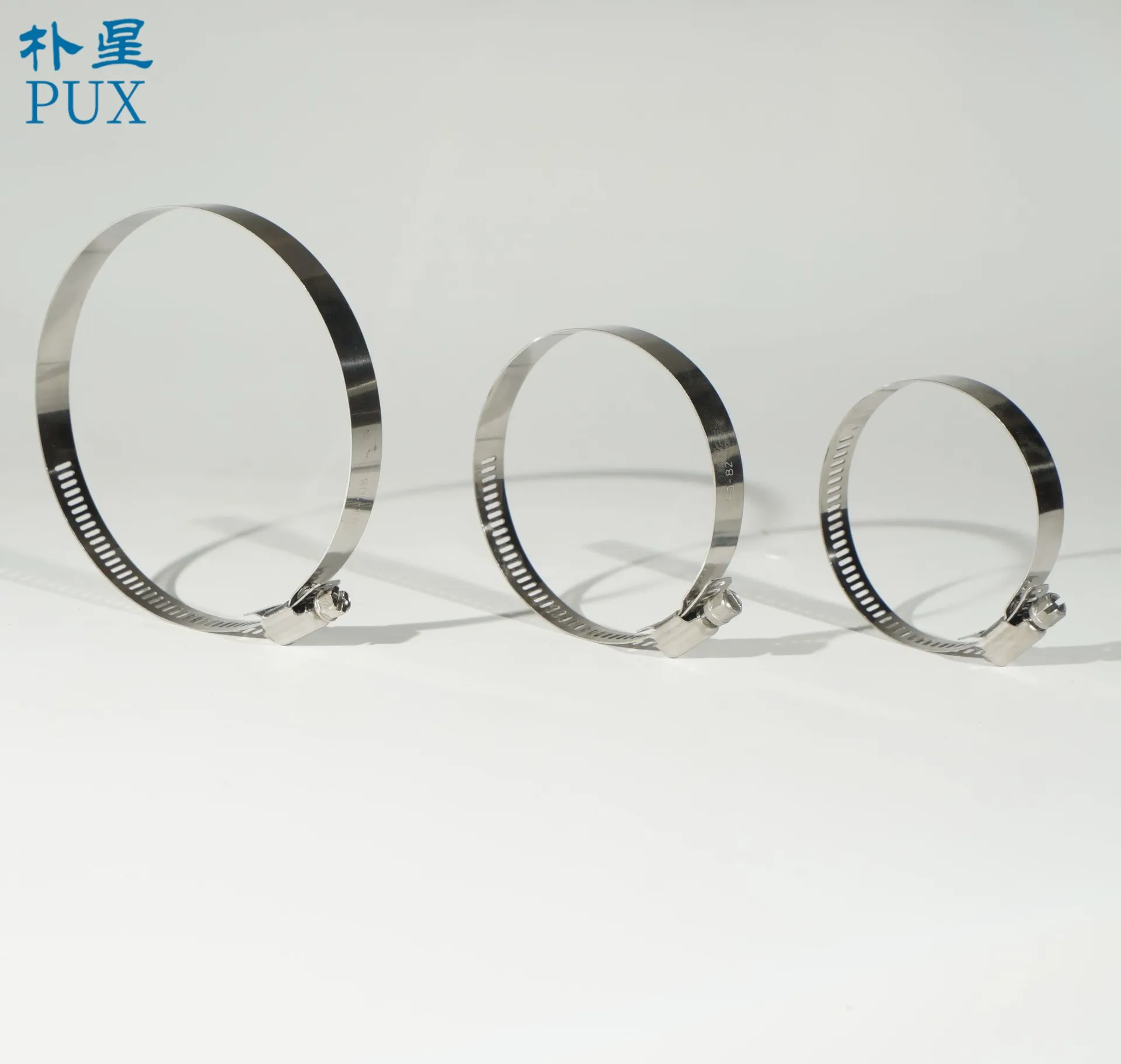

Hose clamps function by compressing a hose tightly around a fitting. This compression prevents the hose from slipping off and helps maintain the seal between the hose and the fitting, thus ensuring fluid remains contained. Hose clamps come in various designs, including worm gear clamps, spring clamps, and constant torque clamps, each serving specific applications and requirements. When selecting a hose clamp, considerations such as material, size, and application environment are of utmost importance.

The Role of 3 8% Hose Clamp Manufacturers

The designation 3 8% refers to a specific standard or quality segment that manufacturers adhere to while producing hose clamps. Companies operating within this classification often incorporate advanced manufacturing processes and high-quality materials, ensuring the resulting products perform optimally under a variety of conditions.

1. High-Quality Materials 3 8% hose clamp manufacturers often utilize high-grade stainless steel, which provides excellent corrosion resistance and durability. This is particularly important in applications where exposure to acids, moisture, or extreme temperatures is common. In addition to stainless steel, some manufacturers may offer clamps made from other materials such as aluminum or plastic, tailored for less demanding environments.

2. Precision Engineering A key feature of reputable 3 8% hose clamp manufacturers is their emphasis on precision engineering. This ensures that each clamp fits its intended application perfectly, reducing the risk of leaks. Advanced manufacturing technologies such as CNC machining and laser cutting are often employed to achieve the desired specifications and tolerances.

3 8 hose clamp manufacturer

3. Versatile Applications The versatility of hose clamps produced by these manufacturers extends across numerous industries. In automotive applications, for instance, they are used to secure coolant hoses, fuel lines, and air intake systems. In plumbing, hose clamps are essential for securing hoses connected to faucets and pipes. Additionally, in industrial settings, they are used in hydraulic and pneumatic systems, ensuring safety and reliability in critical operations.

4. Quality Control and Compliance It is vital for manufacturers to maintain rigorous quality control processes to comply with industry standards. Many 3 8% hose clamp manufacturers undergo certification processes that ensure their products meet or exceed national and international standards. This compliance conveys reliability to customers who depend on the performance of these important components.

The Future of Hose Clamps

As technology advances, so too does the design and manufacturing of hose clamps. Automation and smart manufacturing practices are increasingly being integrated into production workflows, enhancing efficiency and consistency. Innovations in materials and design could yield hose clamps that are lighter, more durable, and even more resistant to adverse conditions.

Additionally, the trend toward sustainable manufacturing practices is likely to influence hose clamp production. Manufacturers may explore eco-friendly materials and processes, catering to consumers and industries focused on reducing their environmental footprint.

Conclusion

In conclusion, the role of 3 8% hose clamp manufacturers is crucial for industries that rely on secure and reliable fluid conveyance systems. Their commitment to quality materials, precision engineering, and adherence to industry standards ensures that the hose clamps they produce are not only effective but also safe for use in various demanding applications. As technology continues to evolve, these manufacturers will likely play a central role in the development of innovative solutions that enhance the performance and sustainability of hose clamps in the future. Whether in automotive, plumbing, or industrial sectors, the importance of high-quality hose clamps remains undisputed, making the choice of manufacturer a critical decision for businesses and consumers alike.

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025