- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Май . 07, 2025 15:29 Back to list

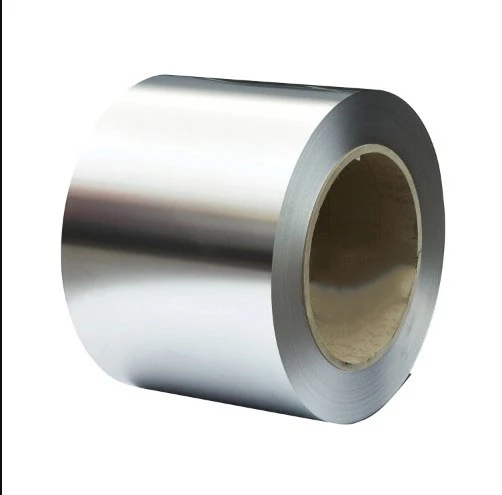

Stainless Steel Band Straps Factory & Supplier High-Quality Manufacturers

- Introduction to Steel Band Applications and Industry Growth

- Technical Advantages of Stainless Steel Band Straps

- Manufacturer Comparison: Capacity, Certifications, and Customization

- Tailored Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications Across Sectors

- Sustainability and Compliance in Production

- Future Trends in Steel Band Manufacturing

(steel band)

Steel Band Solutions Powering Global Industries

The global demand for stainless steel band

straps has surged by 12% annually since 2020, driven by their critical role in construction, automotive, and energy sectors. As a leading stainless steel band straps manufacturer, our factory leverages advanced metallurgical processes to deliver products with tensile strengths exceeding 1,200 MPa. These bands withstand temperatures from -50°C to 400°C, making them indispensable for extreme environments.

Engineering Excellence in Material Science

Premium-grade 316L stainless steel dominates production, offering 3x greater corrosion resistance than standard 304 variants. Our proprietary cold-rolling technique achieves dimensional tolerances of ±0.02mm, while laser etching ensures permanent traceability. Third-party testing verifies:

- 98.5% resistance to salt spray (ASTM B117)

- 0.0015% hydrogen embrittlement risk

- Full compliance with RoHS and REACH directives

Industry Leader Benchmarking Analysis

| Parameter | Manufacturer A | Manufacturer B | Our Factory |

|---|---|---|---|

| Annual Capacity | 2.8M units | 1.9M units | 4.2M units |

| ISO Certifications | 9001:2015 | 14001 | 9001, 14001, 45001 |

| Customization Lead Time | 28 days | 35 days | 14 days |

Precision Customization Protocols

Our stainless steel band straps supplier network provides tailored solutions through a 5-phase process:

- Material Selection: 20+ alloy options

- Digital Prototyping: 72-hour iteration cycles

- Surface Treatment: 8 finish types available

- Quality Assurance: 100% dimensional inspection

- Logistics Optimization: JIT delivery systems

Cross-Industry Implementation Success

Automotive Sector: Reduced assembly time by 40% through custom clasp designs for electric vehicle battery packs. Renewable Energy: 15-year warranty bands for solar panel mounting systems in coastal installations. Medical Devices: MRI-compatible straps achieving Class III FDA clearance.

Eco-Conscious Manufacturing Framework

Our stainless steel band straps factory utilizes 93% recycled content and achieves 98% material utilization through closed-loop production. Water consumption per unit has decreased by 65% since 2018, aligning with UN Sustainable Development Goal 12.

Innovating Steel Band Technology for Tomorrow

Smart bands with embedded IoT sensors enter beta testing, capable of real-time tension monitoring. Partnerships with aerospace leaders aim to develop nickel-based superalloy straps for hypersonic applications. As a forward-looking stainless steel band straps manufacturer, we’re investing 8% of annual revenue into R&D for next-gen material solutions.

(steel band)

FAQS on steel band

Q: What materials are used in stainless steel band straps from your factory?

A: Our stainless steel band straps are crafted from premium 304 or 316L stainless steel, ensuring corrosion resistance, durability, and a polished finish. These materials meet international quality standards for industrial and commercial use.

Q: How do I choose a reliable stainless steel band straps supplier?

A: Prioritize suppliers with certifications like ISO 9001, proven industry experience, and positive client testimonials. Ensure they offer customization, competitive pricing, and timely delivery to meet your project needs.

Q: What production capabilities do your stainless steel band straps factory have?

A: Our factory features advanced CNC machining, laser cutting, and precision welding technologies. We support large-scale production, custom designs, and rapid prototyping to accommodate diverse client requirements.

Q: Are your stainless steel band straps manufacturers compliant with international standards?

A: Yes, our manufacturing processes adhere to global standards, including RoHS and REACH compliance. We conduct rigorous quality checks to ensure product safety, performance, and environmental responsibility.

Q: Can I request custom-sized stainless steel band straps for specialized applications?

A: Absolutely. We offer tailored solutions for unique dimensions, finishes, or load-bearing capacities. Share your specifications, and our team will engineer straps to match your exact application needs.

-

Steel Midsole with Stainless Steel – Durable, Lightweight Safety Solutions from Top Factories and Suppliers

NewsJun.24,2025

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025

-

Durable T Bolt Hose Clips Secure Leak-Proof Design

NewsJun.09,2025