- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Июл . 22, 2024 02:14 Back to list

Leading Manufacturers of High-Quality Pressure Hose Clamps for Optimal Performance and Durability

The Importance of Pressure Hose Clamps in Various Industries

Pressure hose clamps are critical components in a vast array of industrial applications, serving as essential tools for securing hoses and ensuring leak-free performance. With manufacturers across the globe specializing in the production of these clamps, the significance of quality and reliability cannot be overstated. In this article, we will explore the various aspects of pressure hose clamps, including their types, applications, and considerations when selecting a manufacturer.

Understanding Pressure Hose Clamps

Pressure hose clamps are designed to hold hoses tightly and prevent the flow of fluids or gases from leaking. They are available in several types, including worm gear clamps, spring clamps, and bolt clamps, each suited for specific applications. The choice of clamp often depends on factors such as the hose material, the pressure of the fluid being transported, and the operating environment.

Worm gear clamps, for instance, offer adjustability and are suitable for a wide range of applications, from automotive to industrial. They feature a metal band that tightens around the hose with the help of a screw mechanism. Spring clamps, on the other hand, provide quick and easy installation and are commonly used in situations where frequent disconnection is necessary. Bolt clamps offer a more robust solution for high-pressure applications, ensuring a secure and stable fit.

Applications Across Industries

Pressure hose clamps find applications in numerous industries, including automotive, aerospace, manufacturing, and agriculture. In the automotive sector, they are used to secure fuel and coolant hoses, ensuring that engines operate efficiently without the risk of leaks. In aerospace, where precision is paramount, high-quality clamps are crucial for the safety and performance of aircraft.

pressure hose clamps manufacturers

Manufacturing applications often require pressure hose clamps to securely fasten hoses that transport materials in processing systems. With the rise of automation and advanced machinery, these clamps help maintain the integrity of production processes. Agriculture also relies on pressure hose clamps for irrigation systems, fuel lines, and chemical transport, where reliability and durability are essential.

Choosing the Right Manufacturer

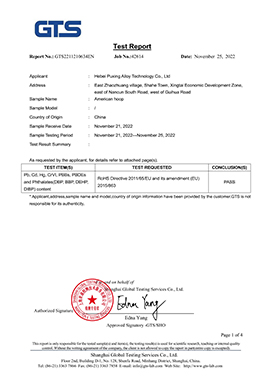

When it comes to selecting a pressure hose clamp manufacturer, several factors should be taken into consideration. Quality standards are paramount; manufacturers should adhere to industry standards such as ISO certifications and offer products that are rigorously tested for performance and durability. The materials used in manufacturing the clamps, such as stainless steel or plastic, should also be considered, especially for high-pressure or corrosive environments.

Additionally, the manufacturer's experience and reputation in the industry can provide insights into the reliability of their products. Companies that have been in the business for a long time often have a proven track record of delivering high-quality solutions. Customer service is another vital component; a good manufacturer should be able to support customers with technical assistance and readily available products.

The Future of Pressure Hose Clamps

As industries continue to evolve, the demand for innovative solutions in hose management will grow. The advent of smart technologies and automated systems may lead to the development of pressure hose clamps with integrated monitoring capabilities, allowing for real-time data collection and analysis. This evolution will help industries enhance efficiency and safety, significantly impacting productivity and operational costs.

In conclusion, pressure hose clamps are indispensable in various industrial applications, ensuring secure and leak-free connections. The choice of clamp type, application context, and manufacturer all play crucial roles in achieving optimal performance. As manufacturers continue to innovate, the future of pressure hose clamps looks promising, with advancements that could potentially transform how we manage fluid and gas transportation across numerous sectors.

-

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025