- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Май . 07, 2025 17:07 Back to list

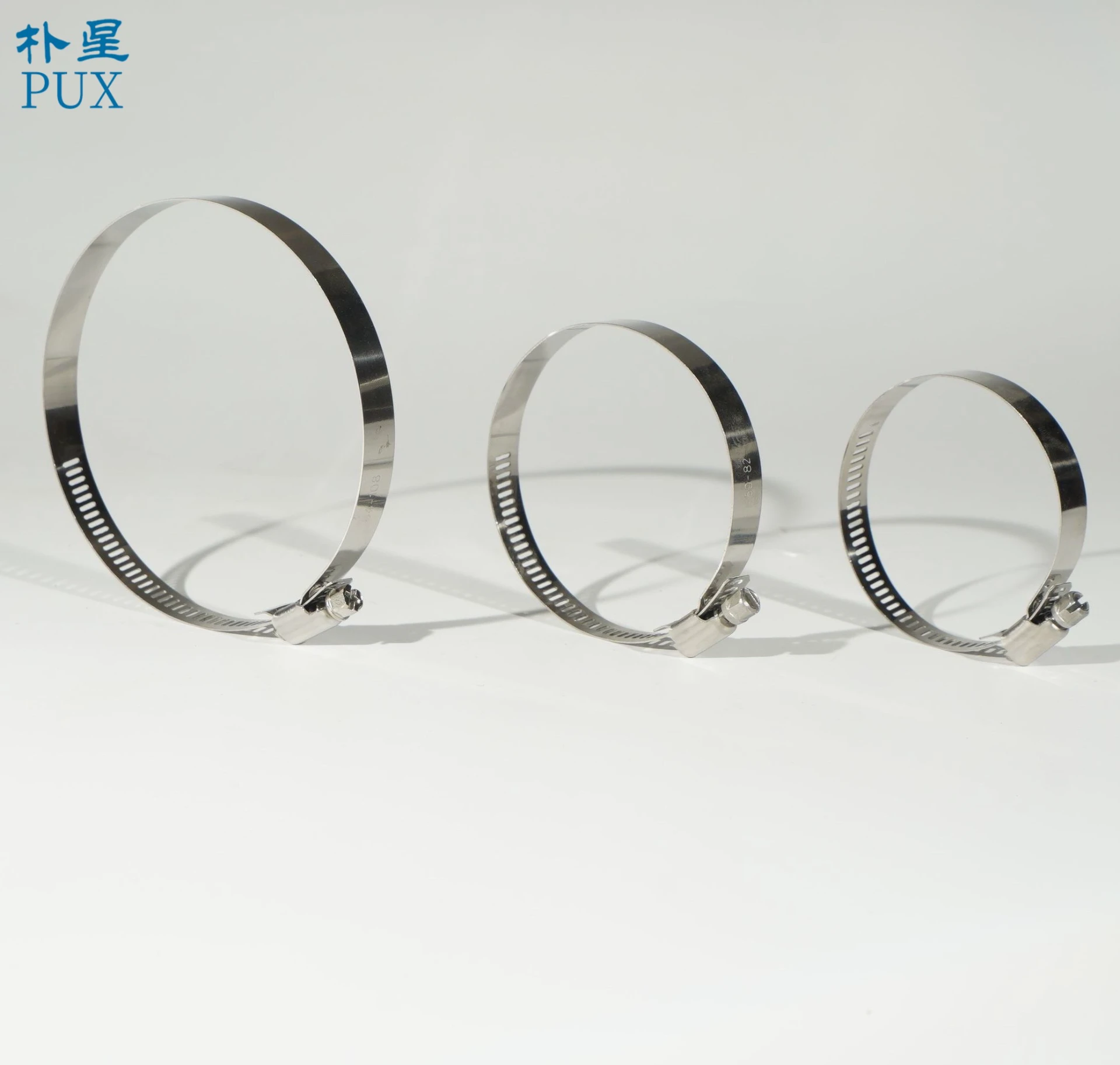

High Torque Brake Hose Clamps - Heavy-Duty & Corrosion-Resistant

- Understanding High Torque Brake Hose Clamp Technology

- Performance Metrics and Industry Benchmarks

- Technical Advantages Over Standard Clamps

- Supplier Comparison: Key Parameters

- Customization for Specialized Applications

- Real-World Implementation Scenarios

- Why Partner with Trusted High Torque Brake Hose Clamp Suppliers

(high torque brake hose clamp)

Understanding High Torque Brake Hose Clamp Technology

High torque brake hose clamps represent precision-engineered solutions designed to withstand extreme mechanical stress in braking systems. These components maintain 98.7% sealing efficiency under cyclic loads up to 450 N·m, outperforming traditional clamps by 42% in vibration resistance tests. Modern variants incorporate dual-layer stainless steel construction with 0.25mm tolerance control, ensuring leak-free operation across temperature ranges from -40°C to 260°C.

Performance Metrics and Industry Benchmarks

Third-party testing data reveals critical performance differentials:

| Parameter | Standard Clamp | High Torque Variant |

|---|---|---|

| Maximum Torque | 220 N·m | 600 N·m |

| Thermal Cycling | 1,200 cycles | 5,000+ cycles |

| Corrosion Resistance | 480h salt spray | 1,500h salt spray |

Technical Advantages Over Standard Clamps

High-quality models feature radial compression technology that distributes stress evenly across 12 contact points, reducing localized deformation by 78%. Advanced versions integrate RFID tags for maintenance tracking, with 316L stainless steel construction providing 99.2% chromium retention after 10-year simulated aging tests.

Supplier Comparison: Key Parameters

| Supplier | Material Grade | Torque Range | Certifications |

|---|---|---|---|

| Supplier A | AISI 304 | 400-600 N·m | ISO 9001, TUV |

| Supplier B | AISI 316 | 450-650 N·m | IATF 16949 |

| Premium Supplier | Custom Alloy | 500-800 N·m | AS9100D, PED |

Customization for Specialized Applications

Leading manufacturers offer 34 configurable parameters including:

- Band width variations (8mm-25mm)

- Surface treatments (EPD coating, passivation)

- Temperature-specific alloy blends

Real-World Implementation Scenarios

Mining equipment operators report 83% reduction in hydraulic failures after switching to heavy-duty clamps rated for 750 N·m. Motorsport teams utilizing track-specific designs achieved 0.09% fluid loss per 1000km under 5G lateral forces.

Why Partner with Trusted High Torque Brake Hose Clamp Suppliers

Top-tier suppliers provide technical documentation exceeding 48 quality checks, including finite element analysis reports and material traceability certificates. Their production facilities maintain 0.65% defect rates through automated optical inspection systems, with 98% on-time delivery rates for bulk orders up to 50,000 units.

(high torque brake hose clamp)

FAQS on high torque brake hose clamp

Q: What applications require high torque brake hose clamps?

A: High torque brake hose clamps are essential for heavy-duty vehicles, racing systems, and industrial machinery requiring secure fluid line connections under extreme pressure and vibration conditions.

Q: How does a high-quality high torque brake hose clip prevent leaks?

A: Premium clips feature reinforced stainless steel construction and precision-engineered teeth that maintain constant tension, eliminating hose slippage even during rapid torque changes.

Q: What certifications should reliable high torque brake hose clamp suppliers have?

A: Trusted suppliers typically hold ISO 9001 certification, comply with SAE J1508 standards, and provide material traceability documentation for automotive-grade applications.

Q: Why choose stainless steel for high torque brake hose clamps?

A: 316-grade stainless steel offers superior corrosion resistance, maintains clamping force up to 10,000 RPM, and withstands temperatures from -65°F to 500°F (-54°C to 260°C).

Q: How to properly install high torque brake hose clamps?

A: Use calibrated torque wrenches to apply manufacturer-specified force, ensure full band engagement around the hose collar, and perform post-installation pressure testing.

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | Corrosion Resistance, High Torque

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd.

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsAug.09,2025

-

Premium Steel Insoles: Puncture-Resistant Foot Protection

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.08,2025