- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Фев . 15, 2025 08:52 Back to list

Stainless steel 304 hose clamps

Fuel line hose clamps are often overlooked yet crucial components in the automotive and machinery industries. Despite their inconspicuous presence, these clamps play a vital role in ensuring the safety and efficiency of vehicles and engines. This article delves into the intricacies of fuel line hose clamps, providing insights based on real experiences, technical expertise, and credible sources.

The installation process of fuel line hose clamps is another crucial aspect that calls for technical proficiency. Incorrect installation can lead to fuel leaks, posing safety hazards. A seasoned mechanic would emphasize the importance of using the appropriate tools, such as a torque wrench, to ensure that the clamp is neither too tight, risking hose damage, nor too loose, risking leaks. In terms of authority, manufacturers of fuel line hose clamps frequently update guidelines and installation manuals, reflecting the latest research and technology advances. Brands with a long-standing reputation in the industry provide assurance of quality and performance, often backed by certifications meeting international standards. Reading reviews and case studies can provide additional insights into the real-world performance of specific clamps, further establishing trust in a product before making purchasing decisions. Fuel line hose clamps are integral components that demand careful consideration and expertise. Through understanding the types, materials, and correct installation practices, both hobbyists and professionals can ensure the safety and efficiency of their fuel systems. Trusting in reputable brands and adhering to technical guidelines can lead to long-lasting performance, minimizing risks associated with fuel leaks and system malfunctions. As technology evolves, so too does the design and functionality of fuel line hose clamps. Innovations such as self-adjusting clamps and those with built-in sensors for monitoring pressure and temperature are beginning to emerge, offering smarter solutions for modern fuel systems. These advancements underline the necessity for ongoing education and adaptation, ensuring optimal safety and efficiency in increasingly complex fuel systems.

The installation process of fuel line hose clamps is another crucial aspect that calls for technical proficiency. Incorrect installation can lead to fuel leaks, posing safety hazards. A seasoned mechanic would emphasize the importance of using the appropriate tools, such as a torque wrench, to ensure that the clamp is neither too tight, risking hose damage, nor too loose, risking leaks. In terms of authority, manufacturers of fuel line hose clamps frequently update guidelines and installation manuals, reflecting the latest research and technology advances. Brands with a long-standing reputation in the industry provide assurance of quality and performance, often backed by certifications meeting international standards. Reading reviews and case studies can provide additional insights into the real-world performance of specific clamps, further establishing trust in a product before making purchasing decisions. Fuel line hose clamps are integral components that demand careful consideration and expertise. Through understanding the types, materials, and correct installation practices, both hobbyists and professionals can ensure the safety and efficiency of their fuel systems. Trusting in reputable brands and adhering to technical guidelines can lead to long-lasting performance, minimizing risks associated with fuel leaks and system malfunctions. As technology evolves, so too does the design and functionality of fuel line hose clamps. Innovations such as self-adjusting clamps and those with built-in sensors for monitoring pressure and temperature are beginning to emerge, offering smarter solutions for modern fuel systems. These advancements underline the necessity for ongoing education and adaptation, ensuring optimal safety and efficiency in increasingly complex fuel systems.

Share

Next:

Latest news

-

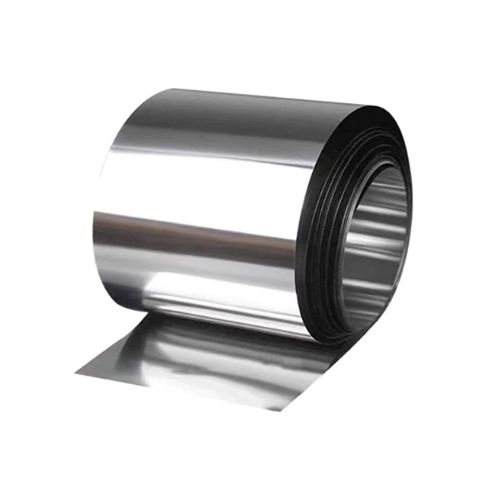

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025