- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Окт . 17, 2024 14:46 Back to list

72 hose clamp manufacturers

An Overview of Hose Clamp Manufacturers A Deep Dive into the 72% Market Segment

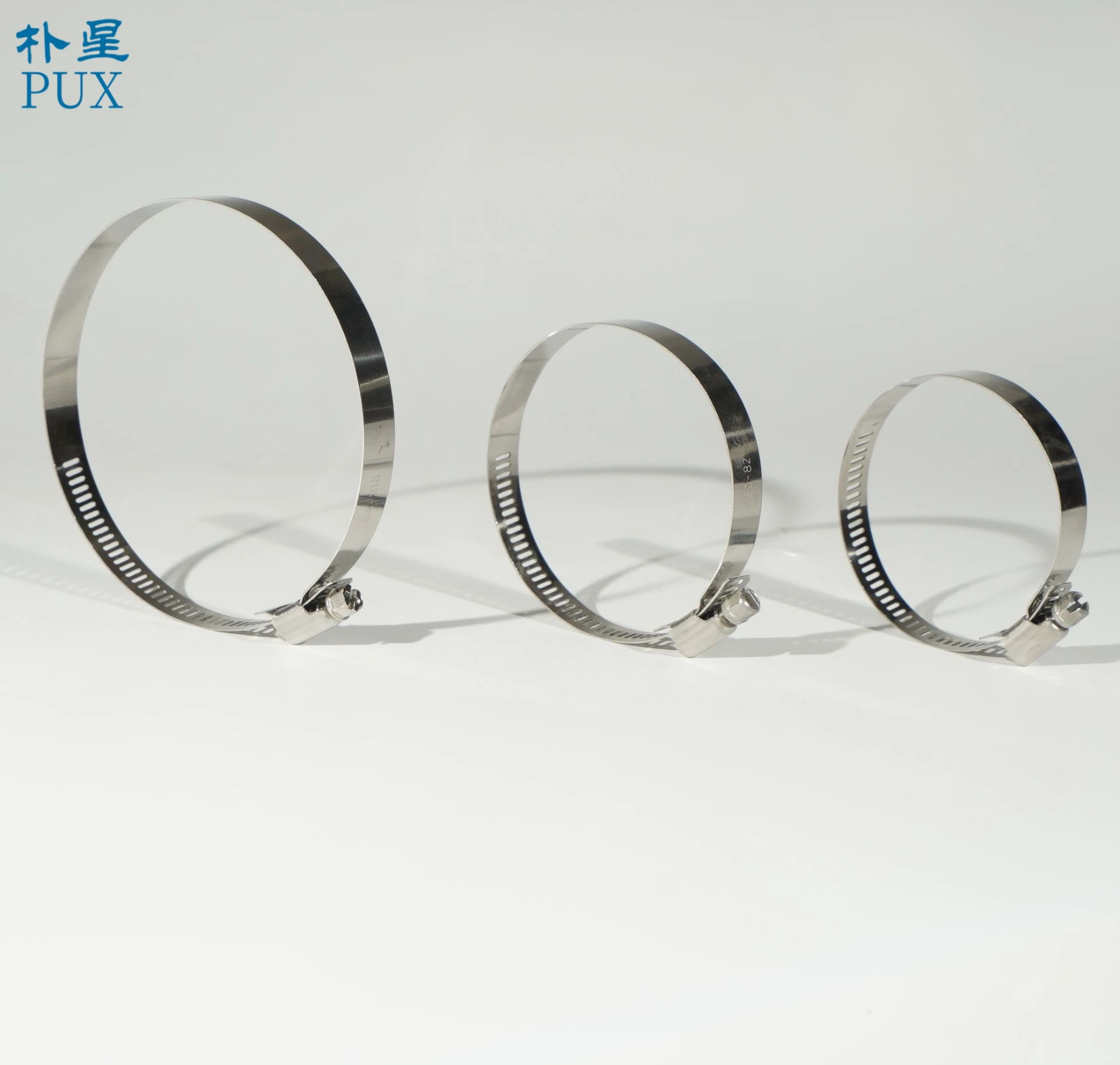

Hose clamps are crucial components in a variety of applications, serving as fastening devices that secure hoses in place to prevent leaks in plumbing, automotive, and industrial settings. They come in various designs and materials, catering to diverse needs across different industries. Amidst this landscape, a significant portion of the market—accounting for approximately 72%—is dominated by a select group of hose clamp manufacturers. This article explores the characteristics, key players, and trends in this extensive sector.

The Importance of Hose Clamps

Hose clamps may seem like small, mundane components, but their role is pivotal. They ensure that hoses remain tightly secured, which is essential for maintaining pressure and preventing fluid leakage in systems ranging from car engines to household plumbing. The reliability of a hose clamp can determine the safety and efficiency of an entire system, making the quality of manufacturers critical.

Manufacturer Analysis The 72% Market Share

The 72% market segment refers to hose clamp manufacturers that hold a considerable share of the global market, indicating potential for stability and innovation. Companies within this bracket often distinguish themselves through quality, cost-efficiency, and technological advancements.

1. Quality Assurance The leading manufacturers prioritize quality control, utilizing advanced materials such as stainless steel and specialized coatings that enhance corrosion resistance. These factors are vital, especially in industries where environmental conditions can lead to premature failure.

2. Diversity in Product Range The top manufacturers often provide a wide array of hose clamp types, including worm gear clamps, spring clamps, and fuel line clamps. This diversity allows customers from various sectors, such as automotive, aerospace, and agriculture, to find suitable products that meet their specific requirements.

3. Technological Innovation New manufacturing technologies, such as laser welding and automated production lines, enable manufacturers to improve precision and reduce production costs. This innovation allows for better scalability and the introduction of custom solutions, further fueling their market presence.

Key Players in the Market

Several manufacturers stand out in this 72% segment, each contributing uniquely to the hose clamp industry

72 hose clamp manufacturers

- Parker Hannifin Known for its broad range of hose management solutions, Parker Hannifin is a significant player. They offer high-quality clamps designed for heavy-duty applications across various industries. - Eaton Corp Another leading manufacturer, Eaton provides exceptional hose clamps that meet stringent safety and performance standards, particularly in the automotive sector.

- Bungartz Specialized in industrial applications, Bungartz offers custom hose clamps that cater to specific needs, enhancing their competitiveness in niche markets.

- Norma Group This international company is recognized for its innovative fastening solutions, including hose clamps, with a strong emphasis on research and development

.Trends Shaping the Industry

As the demand for hose clamps continues to evolve, several key trends are currently shaping the industry

1. Sustainability Increasing awareness around environmental issues is driving manufacturers to use sustainable materials and production processes that minimize carbon footprints.

2. Smart Integration The advent of smart technologies is leading to the creation of hose clamps integrated with sensors that monitor pressure and detect potential leaks, enhancing safety and efficiency.

3. Globalization The growth of global supply chains has enabled manufacturers to access new markets, leading to increased competition and innovation.

4. Customization Customers are seeking more specialized solutions tailored to their unique applications, prompting manufacturers to expand their offerings and develop custom solutions.

Conclusion

The landscape of hose clamp manufacturing, particularly the 72% market segment, is characterized by a mix of established companies and innovative newcomers. As industries continue to evolve, the demand for high-quality, reliable hose clamps will remain strong. Manufacturers that can harness technological advancements, prioritize sustainability, and respond to the customization needs of their clients are well-positioned for success in this dynamic market. As we look ahead, the ongoing developments in materials science and manufacturing technology promise a future where hose clamps will not only fulfill their traditional roles but will also contribute to enhancing the overall efficiency and safety of countless applications worldwide.

-

High-Quality Steel Plate Midsole - Trusted Factory & Suppliers for Safety Footwear

NewsJul.06,2025

-

High-Quality Stainless Steel Slit Coil Supplier & Factory – Precision Slitting, OEM Service

NewsJul.06,2025

-

High-Quality Hose Clamps Mini Clamp – Reliable Factory & Leading Suppliers

NewsJul.05,2025

-

High-Quality Steel Plate Midsole Leading Steel Plate Midsole Factories & Suppliers

NewsJul.05,2025

-

Adjustable Pipe Tube Clip – High-Quality, Durable & Versatile Clamps for Industrial Use

NewsJul.05,2025

-

German Style Hose Clamp Manufacturer Quick Lock Worm Gear Hose Clamp Supplier

NewsJul.04,2025