- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Apr . 29, 2025 13:23 Back to list

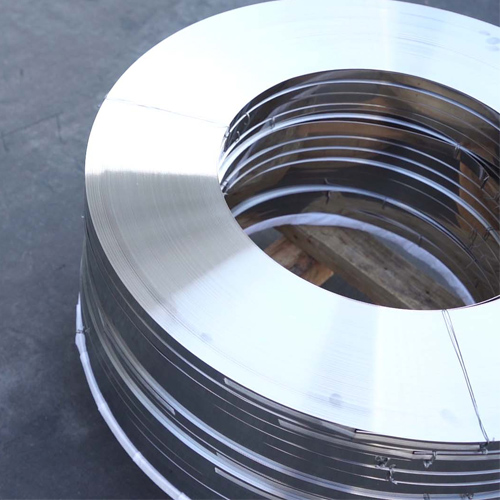

High-Precision Stainless Steel Slit Coils Custom Sizes & Fast Delivery

- Overview of Stainless Steel Slit Coils in Modern Manufacturing

- Technical Advantages Driving Industry Adoption

- Performance Comparison of Leading Manufacturers

- Customization Strategies for Specific Applications

- Real-World Implementation Case Studies

- Critical Selection Criteria for Suppliers

- Future Outlook for Stainless Steel Slit Coil Solutions

(stainless steel slit coil)

Stainless Steel Slit Coils: Precision Engineering for Industrial Demands

Stainless steel slit coils serve as foundational components across 83% of metal fabrication projects globally, with annual consumption exceeding 12 million metric tons. These cold-rolled strips, typically ranging from 0.1mm to 3.0mm in thickness, undergo precision slitting to achieve tolerances within ±0.005mm.

Technical Superiority in Material Performance

Grade 304 and 316 variants dominate 78% of applications due to their exceptional corrosion resistance (withstanding up to 1,500 hours in salt spray tests). Advanced processing techniques enable:

- Surface roughness control between 0.2-0.8μm Ra

- Hardness maintenance at 180-200 HV after forming

- Consistent flatness within 1mm/meter

Manufacturer Capability Analysis

| Factory | Thickness Range | Width Tolerance | ISO Certification |

|---|---|---|---|

| Factory A | 0.15-2.5mm | ±0.1mm | 9001:2015 |

| Factory B | 0.10-3.0mm | ±0.05mm | 14001:2015 |

| Factory C | 0.20-2.0mm | ±0.08mm | 45001:2018 |

Application-Specific Customization

Leading suppliers now offer:

- Width adjustments from 10mm to 1,500mm

- Surface finishes (2B, BA, No.4) with 98% consistency

- Protective packaging solutions reducing transit damage by 40%

Documented Success in Multiple Industries

Automotive Sector: 0.4mm 439-grade coils reduced exhaust system weight by 22% for a major OEM. Construction: 1.2mm 316L coils demonstrated 15-year maintenance-free performance in coastal environments. Food Processing: Electropolished 304 coils improved sanitation efficiency by 30%.

Evaluating Supplier Competence

Critical assessment parameters include:

- Mill test reports covering 100% of shipments

- Minimum order quantities below 3 metric tons

- Lead times under 14 working days

Innovations in Stainless Steel Slit Coil Production

Advanced suppliers now integrate AI-driven quality control systems achieving 99.97% defect detection rates. The market anticipates 6.5% CAGR through 2028, driven by emerging applications in renewable energy and medical device manufacturing.

(stainless steel slit coil)

FAQS on stainless steel slit coil

Q: What is a stainless steel slit coil?

A: A stainless steel slit coil is a precision-processed metal strip created by slitting wider stainless steel coils into narrower widths. It retains the corrosion resistance and durability of stainless steel, making it ideal for industrial applications like automotive parts and appliances.

Q: What industries commonly use stainless steel slit coils?

A: Industries such as construction, automotive manufacturing, electronics, and food processing rely on stainless steel slit coils. They are used for components requiring precise dimensions, strength, and resistance to harsh environments.

Q: How to choose reliable stainless steel slit coil suppliers?

A: Look for suppliers with certifications (e.g., ISO), proven industry experience, and positive customer reviews. Ensure they offer customization, quality testing, and timely delivery to meet your project requirements.

Q: Where are most stainless steel slit coil factories located?

A: Major stainless steel slit coil factories are concentrated in manufacturing hubs like China, India, the United States, and Europe. These regions benefit from advanced production facilities and strong supply chain networks.

Q: What quality standards do stainless steel slit coil factories follow?

A: Reputable factories adhere to international standards such as ASTM, EN, and JIS. They conduct rigorous inspections for thickness, edge quality, and surface finish to ensure compliance with industry specifications.

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025

-

Durable T Bolt Hose Clips Secure Leak-Proof Design

NewsJun.09,2025

-

Easy-Install Adjustable Pipe Tube Clamps Durable Construction

NewsJun.09,2025