- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 05, 2024 07:47 Back to list

chrome plated hose clamps manufacturer

Chrome Plated Hose Clamps A Comprehensive Guide to Manufacturing and Application

Hose clamps are essential components in various industries, ranging from automotive to plumbing, as they ensure the secure fastening of hoses to fittings or pipes. Among the various types of hose clamps available in the market, chrome plated hose clamps stand out due to their durability, aesthetic appeal, and corrosion resistance. This article delves into the manufacturing processes, benefits, and applications of chrome plated hose clamps, providing an overview for those interested in understanding this pivotal component better.

Manufacturing Process

The manufacturing of chrome plated hose clamps involves several steps, each integral to ensuring the quality and performance of the final product. The primary materials used are stainless steel or carbon steel, selected for their strength and resilience.

1. Material Selection The choice of material is critical, as it affects not only the strength of the clamp but also its resistance to oxidation and corrosion. Stainless steel is often preferred due to its excellent resistance to rust and harsh environmental conditions.

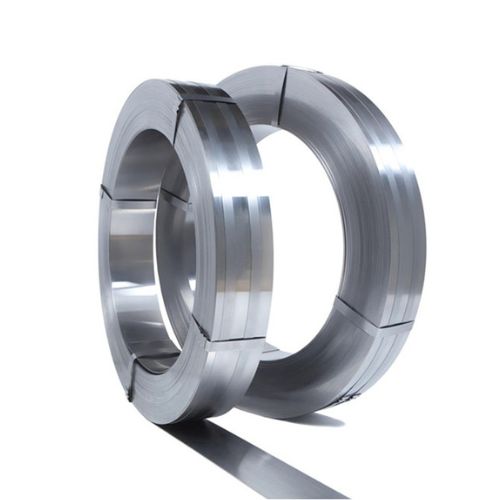

2. Forming The initial step in manufacturing involves cutting the selected steel into strips. These strips are then formed into a circular shape, creating the basic structure of the hose clamp. Various methods, such as stamping or bending, can be used during this phase to ensure precise dimensions.

3. Sizing and Shaping After forming the basic shape, the clamps are then sized appropriately. This ensures that they fit various hose diameters. Different designs and mechanisms, like worm-drive or spring clamps, may also be incorporated based on the intended application.

4. Plating The critical phase of chrome plating involves electroplating the formed clamps. The clamps are submerged in a solution containing chromium, which deposits a thin layer of chrome onto the surface. This plating process enhances the aesthetic appeal while providing superb protection against corrosion, thus extending the lifespan of the clamps.

5. Inspection and Testing Once manufactured, the clamps undergo rigorous quality control checks. This includes testing for tensile strength, flexibility, and resistance to environmental factors. Only those that meet the established quality standards are packaged for distribution.

Benefits of Chrome Plated Hose Clamps

Chrome plated hose clamps offer numerous benefits that make them a preferred choice in various applications

- Corrosion Resistance The chrome plating process provides a robust barrier against moisture and chemicals, significantly reducing the likelihood of rust formation

.chrome plated hose clamps manufacturer

- Aesthetic Appeal The shiny, reflective surface of chrome plated clamps not only looks good but also enhances the overall appearance of the assembly or machinery they are part of.

- Durability These clamps can withstand harsh conditions without deforming or breaking, making them suitable for both indoor and outdoor applications.

- Adjustability Many chrome plated hose clamps are designed with an adjustable mechanism, allowing them to accommodate a range of hose sizes, which adds to their versatility.

Applications

The versatility of chrome plated hose clamps makes them ideal for a wide array of applications

- Automotive Industry They are commonly used in vehicles to secure hoses connecting radiators, valves, and fuel lines, ensuring safety and efficiency in performance.

- Plumbing In plumbing systems, chrome plated clamps are utilized to secure hoses in water supply lines and drainage systems, contributing to leak prevention.

- Manufacturing and Construction These clamps are also used in various industrial applications, including securing air and fluid transfer hoses, which is essential for operational integrity.

- Home Appliances Many household appliances, such as washing machines and dishwashers, rely on chrome plated hose clamps to secure hoses and prevent leaks.

Conclusion

In conclusion, chrome plated hose clamps are an essential component in many sectors due to their excellent properties and benefits. Their manufacturing process, which involves careful material selection and advanced plating techniques, ensures that they are both durable and aesthetically pleasing. Whether in automotive applications, plumbing, or industrial usage, these clamps provide reliability and longevity, making them a critical element in assembling and securing hoses. As industries continue to evolve, the importance of high-quality components like chrome plated hose clamps cannot be overstated.

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025