- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ก.ค. . 23, 2024 14:34 Back to list

Top Manufacturers of 1 8 Inch Hose Clamps for Reliable and Durable Plumbing Solutions

Exploring the World of 1 8 Inch Hose Clamps Factories

Hose clamps are an essential component in various industries, playing a crucial role in securing hoses to fittings and preventing leaks. Among the myriad of hose clamp sizes and types available, the 1 8 inch hose clamp has gained popularity for its versatility and reliability. This article delves into the significance of hose clamp factories that specialize in producing this particular size, highlighting their manufacturing processes, quality control measures, and market impact.

Understanding Hose Clamps

Hose clamps, also known as hose clips, are mechanical devices used to attach and seal a hose onto a fitting such as a barb or a pipe. They can be made from various materials, including stainless steel, plastic, and zinc-plated steel, each suited to different applications. The 1 8 inch size indicates a specific diameter, allowing for a secure fit across a variety of hose types, making it integral in automotive, marine, plumbing, and industrial applications.

Manufacturing Process

The production of 1 8 inch hose clamps involves several stages, starting from raw material acquisition to the final inspection of finished products. Factories typically source high-quality metal or plastic to ensure longevity and resistance to rust and corrosion. The manufacturing process often includes cutting the material to precise sizes, forming it into the desired shape using molding, stamping, or machining techniques, and then applying finishes to enhance durability.

Once the clamps are shaped, they undergo a series of processes to add features like screw threads or notches, which allow for easy tightening and adjustment. This step is crucial as it directly affects the clamp's performance and usability. Automation in this stage has increased efficiency, enabling factories to produce large volumes of clamps while maintaining high quality.

Quality Control Measures

1 8 inch hose clamps factories

Quality is paramount in hose clamp manufacturing, particularly because any failure in a hose clamp can lead to significant leaks or system failures, causing safety hazards and financial losses. Factories implement rigorous quality control measures throughout the production process. This includes raw material inspections, in-process testing, and final product evaluations.

Advanced technologies, such as computer-aided design (CAD) and computer numerical control (CNC) machines, are often used to ensure precision and consistency. Additionally, some factories may employ third-party testing laboratories to validate their products' performance under various conditions, ensuring that they meet industry standards and customer expectations.

Market Impact

The demand for 1 8 inch hose clamps has been steadily increasing, fueled by growth in several sectors including automotive, construction, and agriculture. Factories specializing in this size have had to adapt to changing market dynamics, focusing on both domestic and international markets. With the rise of e-commerce, many hose clamp manufacturers are now able to reach a broader audience, allowing small factories to compete with larger manufacturers.

Moreover, sustainability has emerged as a significant trend, with many factories striving to adopt eco-friendly practices. This includes sourcing recyclable materials and minimizing waste during production. By focusing on sustainable practices, hose clamp factories not only contribute to environmental conservation but also cater to the growing consumer demand for environmentally friendly products.

Conclusion

The 1 8 inch hose clamp factories play a vital role in the manufacturing industry, providing essential components that ensure the safety and reliability of various systems. Through innovative manufacturing processes, stringent quality control measures, and adaptability to market trends, these factories uphold the standard and reputation of hose clamps in various applications. As industries continue to evolve, the role of hose clamp manufacturers will undoubtedly remain significant, driving advances in technology, sustainability, and product quality.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

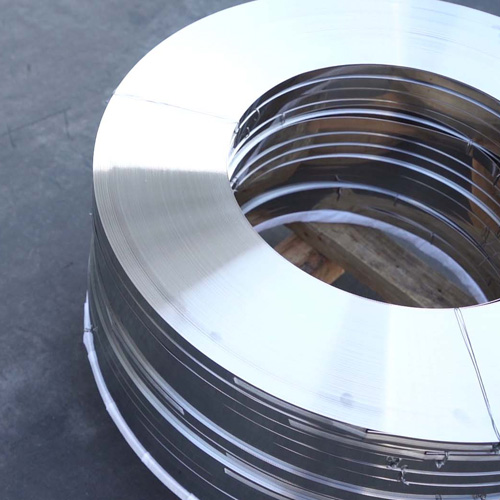

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025