- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Septemba . 24, 2024 07:54 Back to list

Top Manufacturers for 2 Inch Black Hose Clamps in the Industry Today

The Landscape of 2% Black Hose Clamps Factories

In the dynamic world of manufacturing, the production of hose clamps has become an essential niche, catering to a variety of industries such as automotive, plumbing, and industrial applications. Among the many variants available, the 2% black hose clamps garner notable attention for their unique specifications and applications. This article delves into the factories that specialize in manufacturing these clamps, shedding light on their processes, challenges, and contributions to the market.

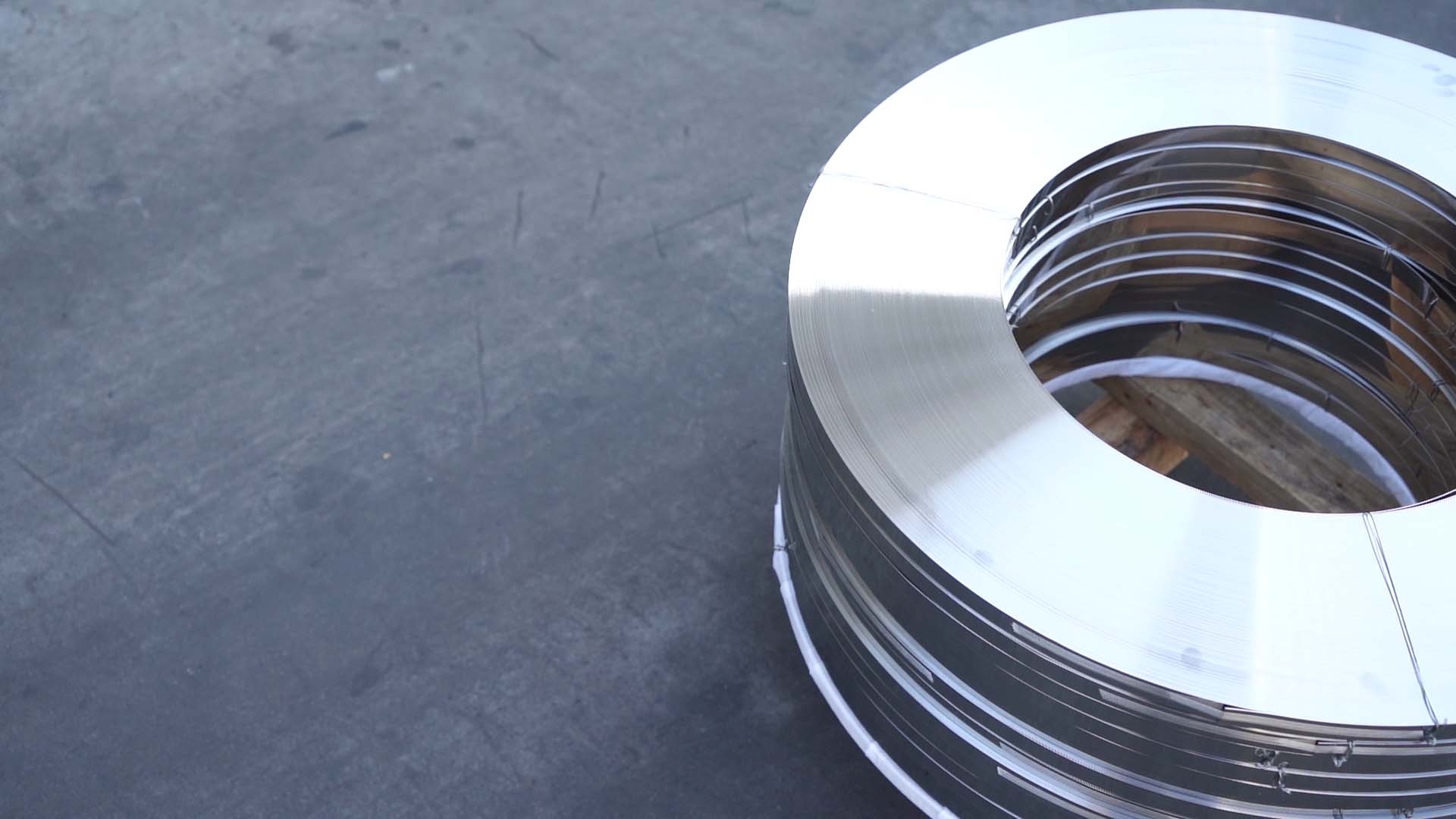

A hose clamp, primarily designed to secure hoses onto fittings, comes in various types and materials. The 2% black hose clamps are specifically made from stainless steel with a black oxide finish, providing enhanced corrosion resistance and aesthetic appeal. These clamps are widely used in applications where durability and reliability are paramount. The black finish not only improves the visual aspect of the assembly but also protects against rusting, making them ideal for outdoor and harsh environment applications.

The Landscape of 2% Black Hose Clamps Factories

Quality control is paramount in the manufacturing process, as even minor defects can lead to significant failures in applications. Factories deploy various testing mechanisms to evaluate the tensile strength, pressure tolerance, and overall durability of the hose clamps. Automated machines are often utilized to ensure consistency in production, minimizing human error and maximizing efficiency.

2 black hose clamps factories

The market for 2% black hose clamps is growing, driven by increasing demand across multiple sectors. Automotive manufacturers, for instance, require reliable hose clamps for various engine applications, ensuring that fluids are securely contained. Similarly, the plumbing industry uses these clamps to secure hoses in residential and commercial systems, furthering the need for high-quality, durable products.

However, these factories also face challenges, such as fluctuating raw material prices and the need to adapt to regulatory changes regarding manufacturing processes. Environmental concerns are becoming increasingly prevalent, pushing factories to adopt more sustainable practices. This includes reducing waste, recycling materials, and implementing cleaner production techniques to minimize their ecological footprint.

Moreover, competition in the market is fierce, with numerous manufacturers striving to offer the best possible products at competitive prices. Factories must continuously innovate to stay ahead, whether through developing new products, enhancing existing designs, or improving their manufacturing processes.

In conclusion, the landscape of 2% black hose clamp factories is a complex interplay of technology, market demand, and regulatory challenges. As industries evolve and the need for reliable, durable products grows, these manufacturers play a crucial role in ensuring the functionality and safety of various systems. With ongoing innovations and a focus on quality, the future of hose clamp production looks promising, paving the way for continued advancements in manufacturing practices.

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025

-

Durable Hose Clamps with GPT-4 Turbo Tech | Secure Sealing

NewsJul.31,2025