- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Oct . 16, 2024 22:07 Back to list

worm drive hose clamp manufacturer factories

The Importance of Worm Drive Hose Clamps in Manufacturing A Spotlight on Leading Factories

Worm drive hose clamps are essential components in various industrial and automotive applications, serving to secure hoses and tubes in place. With their adjustable tightening mechanism, these clamps can accommodate a range of hose diameters, making them versatile tools in the manufacturing sector. In recent years, the demand for high-quality worm drive hose clamps has seen a notable increase, prompting many factories to focus on their production.

Understanding Worm Drive Hose Clamps

A worm drive hose clamp consists of a band, a housing, and a screw that allows the user to adjust the diameter of the clamp. The design is simple yet effective; when the screw is turned, it moves the worm gear within the housing which tightens the band around the hose. This mechanism ensures a secure fit, preventing leakage and disengagement under pressure. Unlike other types of clamps, worm drive clamps offer a more robust option that can withstand varying conditions, making them popular in applications such as automotive fuel lines, radiator hoses, and plumbing.

Key Features of High-Quality Worm Drive Hose Clamps

When sourcing worm drive hose clamps from manufacturers, several features indicate superior quality. First, the materials used are crucial; stainless steel is commonly preferred for its resistance to corrosion and durability. Second, the design of the clamp should allow for even tightening around the hose to avoid damage. Additionally, manufacturers often provide clamps with rolled edges to prevent pinching and cutting of the hoses. High-quality worm drive clamps also feature a smooth operating mechanism that facilitates easy adjustments.

The Manufacturing Process

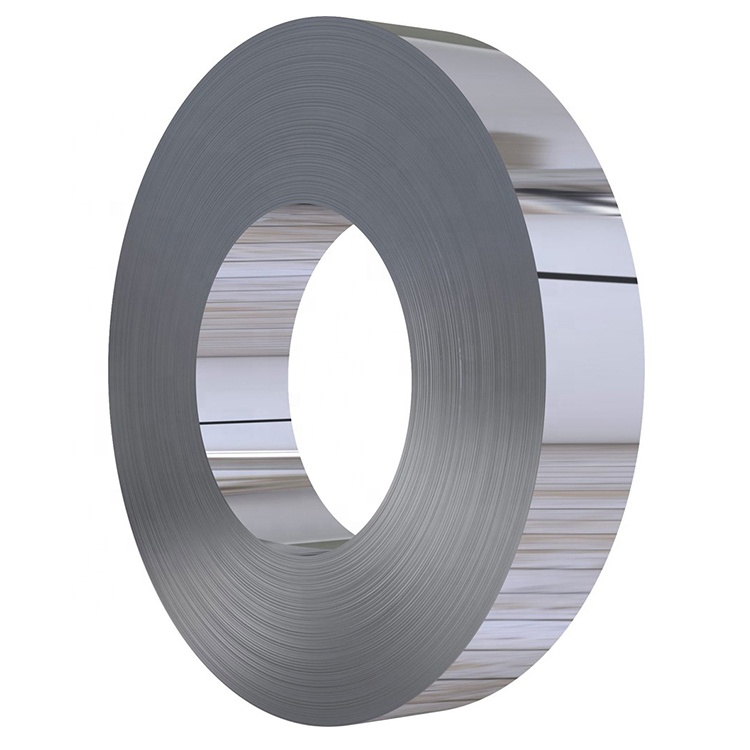

Leading manufacturers employ advanced technologies and strict quality control processes to produce worm drive hose clamps. The manufacturing process generally begins with material selection, where stainless steel or other high-quality metal grades are chosen based on the intended application. The metal is then cut into strips, which are shaped into bands and fitted with housings and screws.

Automation plays a significant role in enhancing production efficiency. Factories utilize CNC machines for precision cutting and bending, ensuring that every component meets rigorous standards. After assembly, the clamps undergo quality control checks to test for strength, durability, and resistance to corrosion. This attention to detail ensures that the final product performs reliably in the field.

worm drive hose clamp manufacturer factories

The Role of Sustainability in Manufacturing

As the global focus shifts toward sustainability, many hose clamp manufacturers are adopting eco-friendly practices. This includes sourcing materials responsibly and implementing waste reduction strategies during the manufacturing process. Some factories are even transitioning to renewable energy sources to power their operations. By prioritizing sustainability, manufacturers not only comply with regulatory requirements but also appeal to environmentally conscious consumers.

A Global Market

The market for worm drive hose clamps is robust, with a steady demand stemming from various sectors, including automotive, aerospace, and plumbing. With the growth of these industries worldwide, factories that specialize in the production of worm drive clamps have the opportunity to expand their reach. Many manufacturers are now exporters, catering to international demand and adapting their products to meet different regional standards and regulations.

Finding the Right Manufacturer

For businesses looking to source worm drive hose clamps, it is important to partner with experienced and reputable manufacturers. Researching potential suppliers should involve evaluating their production capabilities, quality certifications, and customer reviews. Additionally, engaging with manufacturers for inquiries about customization options can lead to tailored solutions for specific applications.

Conclusion

In conclusion, worm drive hose clamps play a vital role in various applications across industries, and their production is a significant focus for many factories worldwide. By understanding the essential features of high-quality clamps, the manufacturing process, and the importance of sustainability, businesses can make informed decisions when sourcing these components. In an ever-evolving market, partnering with the right manufacturer will ensure that companies not only meet their operational needs but also contribute to the broader goals of quality and environmental responsibility.

-

Steel Midsole with Stainless Steel – Durable, Lightweight Safety Solutions from Top Factories and Suppliers

NewsJun.24,2025

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025

-

Durable T Bolt Hose Clips Secure Leak-Proof Design

NewsJun.09,2025