- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Jan . 14, 2025 10:52 Back to list

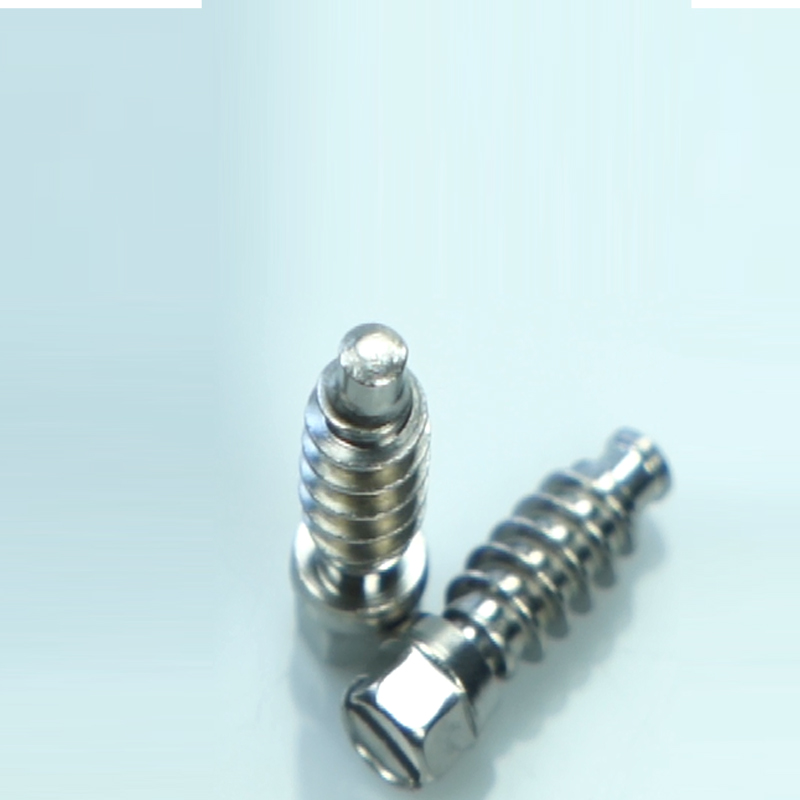

stainless hose clamp

The 1/4 hose clamp might seem like a small, even inconsequential tool in the grand scheme of mechanics and plumbing, but it carries a significant role in ensuring the efficiency and safety of numerous systems. As someone who has worked extensively in both residential and industrial settings, I've come to appreciate not just the utility but the essential nature of these devices.

Professional installers and maintenance crews will attest to their preference for brands that rigorously test their 1/4 hose clamps under real-world stress conditions. Such tests confirm that clamps can withstand vibrations, pressure variations, and environmental impacts without succumbing to loosening or breakage. An important, often overlooked aspect of using 1/4 hose clamps is installation knowledge. Even a high-quality clamp can fail if not installed correctly. Correct installation involves selecting the appropriate size, ensuring proper alignment around the hose, avoiding over-tightening, and regular maintenance checks to identify any potential wear or loosening early on. Authoritative industry bodies, like the SAE (Society of Automotive Engineers), provide guidelines on hose clamp standardization, reinforcing their importance and offering a benchmark for users to ensure optimal performance and safety in their applications. Compliance with such standards is a testament to the clamp's resilience and operational reliability. In conclusion, while the 1/4 hose clamp may be small, it is a vital component in the integrity of fluid transport systems. Understanding its specifications, installation, and maintenance requirements enriches its dependable use across various applications. Mastering these elements not only maximizes your system’s efficiency but also fortifies trust in the equipment we rely on every day, making sure everything runs smoothly, securely, and effectively.

Professional installers and maintenance crews will attest to their preference for brands that rigorously test their 1/4 hose clamps under real-world stress conditions. Such tests confirm that clamps can withstand vibrations, pressure variations, and environmental impacts without succumbing to loosening or breakage. An important, often overlooked aspect of using 1/4 hose clamps is installation knowledge. Even a high-quality clamp can fail if not installed correctly. Correct installation involves selecting the appropriate size, ensuring proper alignment around the hose, avoiding over-tightening, and regular maintenance checks to identify any potential wear or loosening early on. Authoritative industry bodies, like the SAE (Society of Automotive Engineers), provide guidelines on hose clamp standardization, reinforcing their importance and offering a benchmark for users to ensure optimal performance and safety in their applications. Compliance with such standards is a testament to the clamp's resilience and operational reliability. In conclusion, while the 1/4 hose clamp may be small, it is a vital component in the integrity of fluid transport systems. Understanding its specifications, installation, and maintenance requirements enriches its dependable use across various applications. Mastering these elements not only maximizes your system’s efficiency but also fortifies trust in the equipment we rely on every day, making sure everything runs smoothly, securely, and effectively.

Share

Next:

Latest news

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025