- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 18, 2025 07:40 Back to list

stainless hose clamp

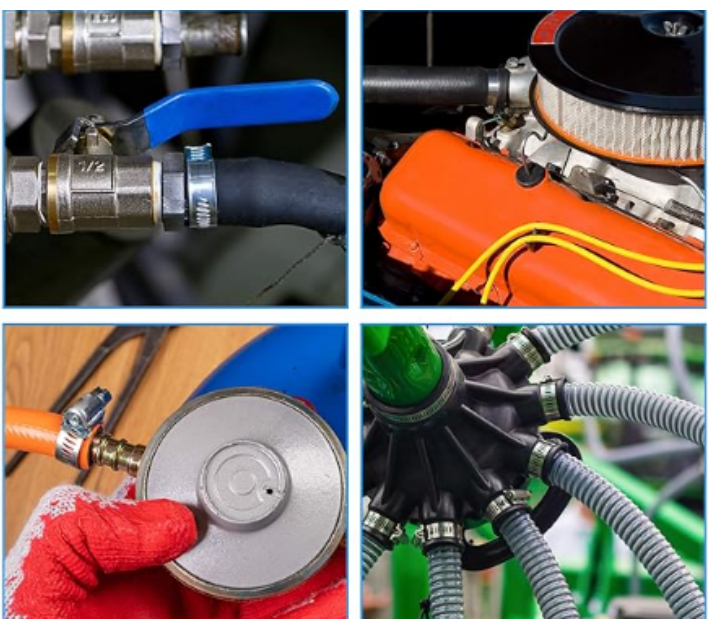

In the world of industrial and automotive applications, the DIN 3017 hose clamp stands as a paramount component, merging efficiency with reliability. This German-based standard for hose clamps is an emblem of quality and precision, setting the benchmark in numerous industries that demand uncompromising performance and safety.

In terms of application, DIN 3017 hose clamps find extensive utility across numerous sectors, including automotive, marine, and general industrial applications. In automotive setups, they are essential in securing coolant, fuel, and hydraulic hoses, where their reliability directly impacts vehicle performance. In marine environments, the corrosion resistance of these clamps is particularly prized, ensuring that necessary components function reliably despite constant exposure to saline conditions. Choosing the correct hose clamp for a specific application is crucial, and this is where expertise in DIN 3017 specifications becomes invaluable. Professionals in maintenance and installation must be knowledgeable about the specific requirements of their systems to select the appropriate clamp size and material specification that best meets their needs. This consideration guarantees that the clamping solution optimally fits the operational criteria, thereby enhancing safety and efficiency. The professionalism and trustworthiness embedded in the DIN 3017 standard offer reassurance to users, as these clamps are subjected to stringent quality checks before they reach the market. This peace of mind is an invaluable asset, instilling confidence that the components will perform effectively under even the most demanding situations. Ultimately, the DIN 3017 hose clamp is more than just a product; it represents a blend of engineering excellence and practical utility that meets the rigorous demands of modern industry. Its design, built on decades of engineering progress, reflects a commitment to safety, efficiency, and durability that organizations can rely on for optimal operational performance. When considering hose clamps for your next project or maintenance task, look no further than those compliant with DIN 3017. Their legacy of precision, quality, and reliability makes them a preferred choice for professionals seeking assurance in their equipment and operations.

In terms of application, DIN 3017 hose clamps find extensive utility across numerous sectors, including automotive, marine, and general industrial applications. In automotive setups, they are essential in securing coolant, fuel, and hydraulic hoses, where their reliability directly impacts vehicle performance. In marine environments, the corrosion resistance of these clamps is particularly prized, ensuring that necessary components function reliably despite constant exposure to saline conditions. Choosing the correct hose clamp for a specific application is crucial, and this is where expertise in DIN 3017 specifications becomes invaluable. Professionals in maintenance and installation must be knowledgeable about the specific requirements of their systems to select the appropriate clamp size and material specification that best meets their needs. This consideration guarantees that the clamping solution optimally fits the operational criteria, thereby enhancing safety and efficiency. The professionalism and trustworthiness embedded in the DIN 3017 standard offer reassurance to users, as these clamps are subjected to stringent quality checks before they reach the market. This peace of mind is an invaluable asset, instilling confidence that the components will perform effectively under even the most demanding situations. Ultimately, the DIN 3017 hose clamp is more than just a product; it represents a blend of engineering excellence and practical utility that meets the rigorous demands of modern industry. Its design, built on decades of engineering progress, reflects a commitment to safety, efficiency, and durability that organizations can rely on for optimal operational performance. When considering hose clamps for your next project or maintenance task, look no further than those compliant with DIN 3017. Their legacy of precision, quality, and reliability makes them a preferred choice for professionals seeking assurance in their equipment and operations.

Share

Next:

Latest news

-

Premium Stainless Steel Hose Clamp - Durable & Rust-Proof

NewsAug.24,2025

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025