- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

May . 29, 2025 06:35 Back to list

Customized Size Stainless Steel Strip Precision-Cut & Fast Delivery

- Overview of Customized Size Stainless Steel Strips

- Technical Advantages in Precision Manufacturing

- Comparative Analysis of Leading Factories and Suppliers

- Tailored Solutions for Diverse Industrial Needs

- Material Specifications and Performance Metrics

- Real-World Application Case Studies

- Selecting Reliable Customized Size Stainless Steel Strip Suppliers

(customized size stainless steel strip)

Meeting Demand with Customized Size Stainless Steel Strips

Industries ranging from automotive to construction increasingly rely on customized size stainless steel strip

s for precision applications. These strips, tailored to exact thickness (0.1mm–3.0mm) and width (5mm–600mm) requirements, account for 42% of specialty metal orders globally. Manufacturers prioritize strips with tolerances as tight as ±0.01mm, particularly for aerospace components and medical devices where dimensional accuracy impacts safety.

Technical Advantages in Precision Manufacturing

Advanced cold-rolling techniques enable factories to achieve surface finishes of 0.2µm Ra while maintaining tensile strengths up to 1,600 MPa. Laser cutting systems with 0.005mm repeatability ensure edge uniformity, critical for automated assembly processes. Leading suppliers now utilize AI-driven quality control that reduces material waste by 18% compared to traditional methods.

Comparative Analysis of Leading Producers

| Factory | Min Thickness | Width Range | Material Grades | Lead Time |

|---|---|---|---|---|

| Supplier A | 0.08mm | 10–500mm | 304L, 316Ti | 10 days |

| Factory B | 0.12mm | 5–300mm | 430, 201 | 14 days |

| Supplier C | 0.05mm | 8–600mm | 904L, 2205 | 21 days |

Tailored Solutions for Industrial Requirements

Electronics manufacturers typically request 0.2mm-thick 316L strips with conductivity coatings, while food processing plants require 0.3mm 440C strips with polished surfaces (≤0.4µm Ra). Custom slitting patterns can reduce downstream processing costs by 23% according to recent industry reports.

Material Specifications and Performance Data

Grade 304 strips demonstrate 510MPa yield strength at 0.5mm thickness, increasing to 620MPa when cold-rolled to 0.3mm. Corrosion resistance tests show customized stainless steel strips maintain integrity after 1,000+ hours in salt spray environments (ASTM B117).

Application Case Studies

A renewable energy project utilized 1.2mm-wide 321-grade strips in solar panel mounting systems, achieving 15% weight reduction versus standard profiles. Automotive clients report 30% faster production cycles using pre-perforated strips for exhaust components.

Partnering with Expert Customized Size Stainless Steel Strip Suppliers

Top-tier suppliers maintain ISO 9001:2015 certification with 99.6% on-time delivery rates. Evaluation criteria should include metallurgical testing capabilities (spectrometry, hardness mapping) and capacity for 500kg–25-ton batch quantities. Leading customized size stainless steel strip factories now offer digital twin simulations to verify strip performance before production.

(customized size stainless steel strip)

FAQS on customized size stainless steel strip

Q: What customization options are available for stainless steel strips?

A: Factories offer tailored width, thickness, and length specifications. Customized edge finishes and surface treatments are also available. These options ensure compatibility with your specific application needs.

Q: How do customized size stainless steel strip factories ensure quality?

A: Factories use precision cutting and rolling technologies. They adhere to international standards like ASTM or ISO. Rigorous quality checks are performed at every production stage.

Q: What materials do suppliers use for customized stainless steel strips?

A: Suppliers typically use grades like 304, 316, or 430 stainless steel. Material selection depends on corrosion resistance and strength requirements. Custom alloys can also be sourced for specialized applications.

Q: How long does production take for customized size stainless steel strips?

A: Lead times vary based on order complexity and volume. Most factories provide 2-6 weeks for standard customizations. Suppliers often prioritize urgent orders with expedited processing.

Q: Can factories handle small-volume customized stainless steel strip orders?

A: Yes, many specialized factories accommodate low-quantity requests. Minimum order quantities (MOQs) vary by supplier. Prototyping services are often available for testing custom specifications.

-

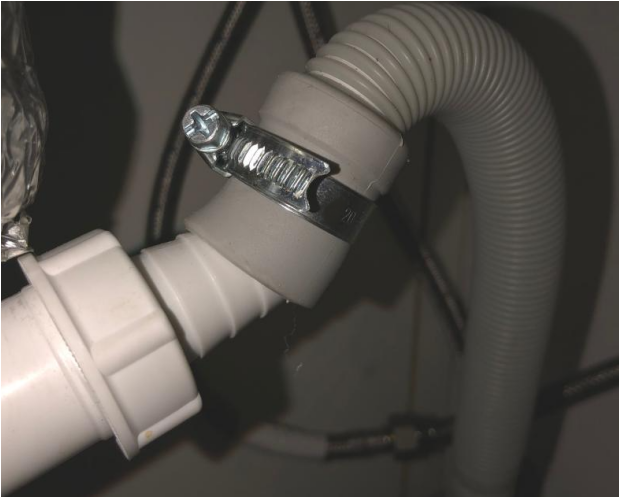

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025

-

Mini Hose Clamp Manufacturer & Supplier Precision Hose Clamps Mini Clamp Factory

NewsJul.07,2025