- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 12, 2024 16:38 Back to list

3mm hose clamp factories

The Landscape of 3mm Hose Clamp Factories A Deep Dive

Hose clamps are integral components in various industries, ensuring secure fittings and leak prevention in hoses and tubing. Among the many sizes and types of hose clamps available, the 3mm hose clamp holds a unique position due to its versatility and widespread use in applications ranging from automotive to agricultural equipment. As the demand for these components grows, so does the emergence of specialized factories dedicated to the production of 3mm hose clamps.

Understanding 3mm Hose Clamps

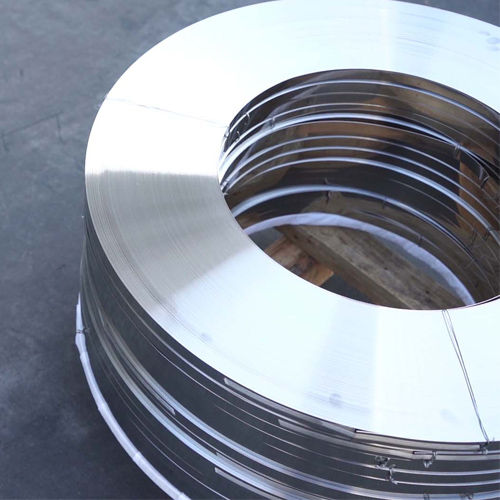

A 3mm hose clamp is generally characterized by its nominal size, which refers to the diameter of the hose it is designed to secure. Typically made from stainless steel, carbon steel, or plastic, the design of these clamps allows for easy installation and adjustment, making them user-friendly and efficient. The clamps function by applying even pressure around the hose, thereby preventing it from slipping or leaking under various conditions.

The Manufacturing Process

The production of 3mm hose clamps is a nuanced process that involves several steps. Raw materials are first selected based on the desired properties such as corrosion resistance, strength, and durability. Stainless steel and brass are popular choices for their resilience and longevity.

Once the materials are procured, the manufacturing process begins with stamping or forming the base of the clamp. This is generally done using automated machinery that ensures precise dimensions. The next step involves assembling the components, which may include screws or locking mechanisms to secure the clamp firmly around the hose.

Quality control plays a critical role in the manufacturing of hose clamps. Factories employ various testing methods to ensure that each clamp meets industry standards. These tests may include pressure tests, corrosion resistance evaluations, and dimensional inspections. By adhering to strict quality assurance practices, these factories ensure the reliability of their products.

3mm hose clamp factories

The Role of Technology

In recent years, technology has transformed the manufacturing landscape of hose clamps. Advanced manufacturing techniques, such as computer numerical control (CNC) machining, enable factories to produce hose clamps with higher precision and efficiency. Automation has also played a key role in optimizing production lines, reducing labor costs, and minimizing human error.

Moreover, the integration of data analytics allows manufacturers to optimize production schedules and inventory management. By analyzing patterns in demand, factories can better anticipate market needs and adjust their production quantities accordingly. This responsiveness is crucial in an ever-evolving marketplace where customer needs may change rapidly.

The Global Market

The global demand for 3mm hose clamps is driven by several industries, including automotive, construction, and HVAC (heating, ventilation, and air conditioning). As these sectors continue to expand, the need for high-quality hose clamps remains strong. Manufacturers are increasingly looking to establish a global presence, exporting their products to meet international demands.

Countries like China, Germany, and Italy are notable players in the hose clamp market. Chinese factories, in particular, have gained a reputation for their cost-effective production methods while maintaining acceptable quality standards. On the other hand, European manufacturers often focus on high-quality, specialized clamps, appealing to niche markets that demand superior performance.

Conclusion

The landscape of 3mm hose clamp factories is a testament to the ingenuity of modern manufacturing. As industries evolve and technology advances, these factories play a crucial role in providing components that are essential for the safety and efficiency of various applications. With continued emphasis on quality, technological enhancement, and global market reach, the future of 3mm hose clamp production looks promising. As industries adapt to new challenges, the humble hose clamp stands out as a critical component in ensuring the smooth operation of countless machines and systems worldwide.

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025