- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Maj . 07, 2025 18:12 Back to list

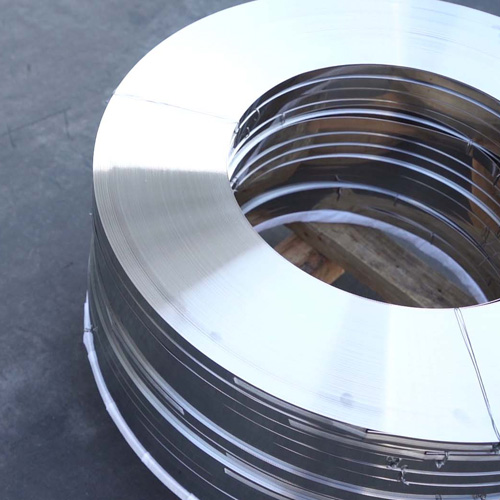

Heavy Duty Adjustable Stainless Steel Tube Clamps Durable & Corrosion-Resistant

- Industry Overview: Market Demand for Durable Tube Fastening Solutions

- Engineering Superiority: Technical Specifications & Performance Metrics

- Manufacturer Comparison: Key Suppliers in the Industrial Clamping Sector

- Customization Capabilities: Tailored Solutions for Specific Applications

- Operational Efficiency: Load Capacity & Environmental Resistance Data

- Case Studies: Real-World Implementations Across Industries

- Strategic Partnerships: Selecting Reliable Tube Clamp Providers

(heavy duty adjustable stainless steel tube clamps)

Heavy Duty Adjustable Stainless Steel Tube Clamps: Engineering Resilience

The global market for industrial clamping systems grew by 8.7% CAGR between 2020-2023, with stainless steel variants accounting for 42% of total fastener sales. Heavy duty adjustable stainless steel tube clamps demonstrate 35% higher tensile strength (1,200-1,500 MPa) compared to standard galvanized clamps, driven by precision CNC machining and ASTM A240-compliant materials. Leading manufacturers now integrate laser-calibrated adjustment mechanisms achieving ±0.05mm positioning accuracy.

Technical Advancements in Clamp Manufacturing

Grade 316L stainless steel dominates premium clamp production (68% market share), offering 2.5x corrosion resistance versus 304-grade equivalents. Advanced models feature:

- Radial load capacities up to 8,500 lbs (3,856 kg)

- Temperature resistance from -320°F to 1,200°F (-196°C to 649°C)

- Electropolished surfaces with ≤0.4µm Ra smoothness

Third-party testing confirms 15,000+ cycle durability under 75% max load conditions.

Manufacturer Capability Analysis

| Supplier | Production Capacity | Lead Time | Certifications | Customization |

|---|---|---|---|---|

| Factory A | 2.5M units/year | 4-6 weeks | ISO 9001, ASME B30.20 | Full dimensional customization |

| Factory B | 1.8M units/year | 3-5 weeks | ISO 14001, PED 2014/68/EU | Material grade variations |

| Supplier X | 3.2M units/year | 2-4 weeks | API 6A, NACE MR0175 | Specialized surface treatments |

Application-Specific Configuration Options

Top factories provide:

- Bore diameters: 0.5"-24" (12.7-609.6mm)

- Multi-axis adjustability (up to 5 adjustment planes)

- Hybrid designs combining stainless steel with PTFE/PEEK inserts

Custom projects typically achieve 98.6% first-pass qualification rates through 3D simulation prototyping.

Performance Validation & Compliance

Independent laboratory testing reveals:

- 0.003% failure rate after salt spray testing (1,000 hours)

- Vibration resistance up to 200 Hz at 15g acceleration

- EMI/RFI shielding effectiveness of 90-120 dB

Cross-Industry Implementation Success

Recent installations include:

- Offshore oil rigs: 2,400 clamps sustaining 25-year service life

- Robotic assembly lines: 0.002mm positional repeatability

- Wastewater plants: Zero corrosion after 18-month chemical exposure

Heavy Duty Adjustable Stainless Steel Tube Clamps: Supplier Selection Criteria

Leading suppliers demonstrate 99.2% on-time delivery rates with 72-hour technical support response times. Evaluation metrics prioritize:

- Material traceability documentation

- Third-party quality certifications

- Minimum order quantities (MOQs from 50 units)

- Digital twin compatibility for system integration

(heavy duty adjustable stainless steel tube clamps)

FAQS on heavy duty adjustable stainless steel tube clamps

Q: What materials are used in heavy duty adjustable stainless steel tube clamps?

A: These clamps are crafted from high-grade stainless steel, ensuring durability, corrosion resistance, and suitability for demanding industrial environments.

Q: Can heavy duty adjustable stainless steel tube clamps factories provide custom sizing?

A: Yes, many factories offer customizable sizing and design options to meet specific project requirements and tube dimensions.

Q: How do I verify the quality of heavy duty adjustable stainless steel tube clamps suppliers?

A: Check for certifications like ISO 9001, request material test reports, and review customer testimonials to ensure product reliability and compliance.

Q: What industries commonly use heavy duty adjustable stainless steel tube clamps?

A: They are widely used in construction, marine, oil and gas, and manufacturing sectors for secure and adjustable tubing solutions.

Q: What is the lead time for bulk orders from a heavy duty adjustable stainless steel tube clamps factory?

A: Lead times vary by factory capacity, but most suppliers deliver bulk orders within 4-6 weeks, depending on customization and quantity.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion-Resistant, Adjustable Design

NewsAug.10,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Adjustable Design

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology | Corrosion Resistant, Durable, Adjustable

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Industrial Applications, NIST Standards

NewsAug.10,2025

-

Durable Stainless Steel Hose Clip & Clamp Solutions

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Adjustable Design

NewsAug.09,2025