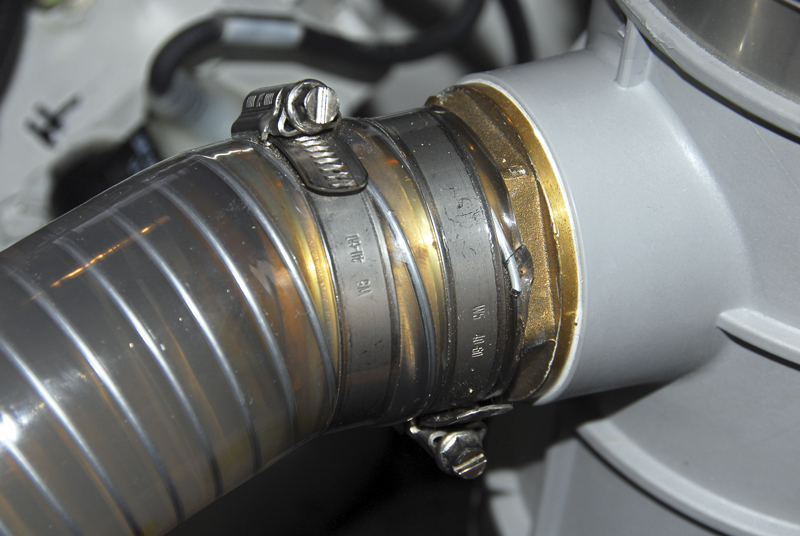

Doubled hose clamps on any fittings that can accommodate them are common and desirable but not essential in the marine industry. For ABYC compliance, two clamps are required only on fuel fills and exhaust hoses.

Humble hose clamps are essential to the integrity of hulls and onboard systems, but their reliability depends on informed selection and best installation practices.

Think for a moment about this sobering truth: someplace in the onboard systems of even the most expensive boats, watertight integrity relies on the unfailing performance of simple thin-metal hose clamps, some costing just a few dollars. While I haven’t seen many vessels sink as a result of hose-clamp failure, that disaster is easily avoided, as are the many less-dramatic results of their failures on fuel-fill and supply plumbing or sanitation and potable-water systems, to name a few. In short, hose clamps are vital to the operation of almost any vessel, and while they seem a mundane bit of inexpensive hardware, mistakes in choosing and installing them can be very costly.

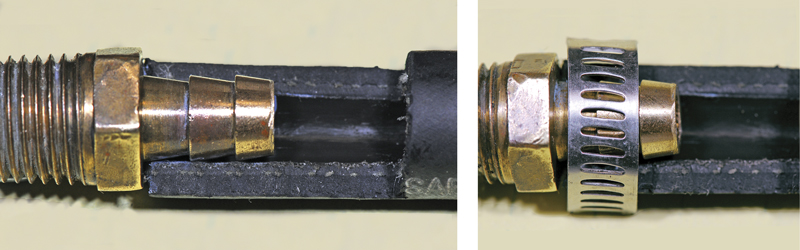

To form an effective seal, hose clamps and the hoses they are applied to must be used with compatible, purpose-made pipe-to-hose adapters, sometimes called hose barbs or bibs. I frequently see hose connections fail because the hose was installed over a pipe fitting not specifically designed to support a clamped-in-place hose.

Left—A tight seal between a hose and a rigid fitting depends on an appropriately sized ridged barb. Right—Where hose barbs are simply too short to support more than one clamp, a single robust clamp is the only viable approach.

The ubiquitous worm-gear hose clamp, relying on a simple screw and threaded band, effectively exerts uniform pressure on hoses and their fittings. As respected as the original design may be, it isn’t flawless. Many hose clamps rely on a series of perforations cut into the band to engage with the screw threads. (Note: The bolt-and-barrel clamp and the T-bolt clamp are two common alternative types that rely on solid metal bands.) These perforations eliminate a significant portion of the band’s cross section, weakening it and allowing it to elongate when tensioned. Elongation leads to microcracking, which in turn provides a toehold for crevice corrosion, a form of metal decay peculiar to stainless steel alloy (see “Power and Peril of Stainless Steel,” in Professional BoatBuilder No. 146). When perforated hose clamps part, they nearly always do so across one of these holes, either as a result of overstress or corrosion, or a combination of both. Also, typical clamp band material is comparatively thin, which makes it easy to strip the perforations if the screw is overtorqued.

Another side effect of the perforated band is the damage it can cause to the hose jacket. It’s not unusual to see a perforated clamp squeezing out tufts of hose in the perforations, cheese-grater style. Some perforated clamps include an inner smooth liner, which eliminates this effect, but it adds cost while also remaining vulnerable to stripping, elongation, and other failures.

Left—Hose clamps that rely on a perforated thread are susceptible to stress-induced corrosion and failure. Right—Another weakness of perforated hose clamps is their vulnerability to overtightening and thread failure.

The typical perforated hose clamp, which I refer to as an automotive clamp, is made of either a stainless steel or galvanized steel band (most clamps sold in North America are stainless steel) with a plated mild-steel screw. On a vehicle, depending upon humidity levels and exposure to road salt, these clamps can be expected to last for 10 to 20 years, but in a marine environment, the plated screw (and galvanized band when present) quickly corrode and fail. Therefore, these standard automotive clamps should never be used in a marine application. Up-rated “marine” models with stainless steel bands and screws are a huge improvement over the automotive version; however, because they retain perforations and scant band thickness, they remain prone to elongation, crevice corrosion, “cheese-grating,” and stripping. You can do better.

To avoid the undesirable “cheese-grater” effect of overtightened perforated clamps, especially on soft silicone-based hoses, use clamps with embossed, rather than perforated, bands.

One challenge for common hose clamps is the need to maintain tension after initial installation. Leaks can result from either compression of softer (often silicone) hoses or variation in temperature. In the former case, over time the hose compresses, which leads to reduced clamp tension, requiring at least one re-tension sometime after the initial installation. (Depending on hose thickness and durometer, temperature, and temperature fluctuation, it could be as soon as a few days and as long as a year.) In the latter case, hoses used on closed cooling systems, for instance, can experience dramatic temperature swings, from below freezing at rest to well above boiling while in use. That in turn can strain a clamp’s capacity to maintain tension on a pressurized hose without causing damage. One solution is a constant-tension clamp, built around either a Belleville spring under the screwhead; or a W-cross-section, lubricated, O-ring-equipped spring liner inside the clamp.

A clamp with a solid band under the perforations protects the hose from the grater effect, but in wet environments it is still vulnerable to microcracking, starting around the perforations.

Both types can maintain constant tension over a range of variable loads and are available in worm-drive and T-bolt models. On the subject of springs, under no circumstances should a clamp that relies on spring tension alone (commonly found on modern automobiles) be used in seagoing applications. In most cases, these are made from mild steel and are thus prone to rust and failure.

Hose Clamps Ready for Sea

Solid-band all-stainless-steel hose clamps are a significant leap in quality and reliability over automotive and standard marine clamps. This clamp style replaces the band perforations with embossed rather than perforated threads, necessitating a thicker band, which resists elongation, cracking, and stripping. Embossed solid-band clamps are virtually immune to stripping even when overtightened, and because they are not perforated, that source of hose damage in standard clamps is also eliminated. The thicker bands of embossed clamps can also be manufactured with slightly upward rolled edges, which are gentler on the hose.

A perforated clamp, left, and a solid-band embossed-thread clamp, right. Not only is the solid band virtually impervious to overtightening and stripping, the thicker metal is less vulnerable to stress cracking.

These clamps are available in a wide variety of sizes from several manufacturers, including Robinson’s Jubilee and NORMA. (See the sidebar below.) Importantly, while all-stainless-steel construction is a prerequisite for true marine clamps, they are often available in either 304 or 316 alloy, with a predictable cost difference. For the most part, unless the clamp will be routinely submerged or exposed to water or spray, 304 alloy clamps work well and cost less. In cases where maximum corrosion resistance is required—stuffing box and bilge pump hoses—then the higher price of 316 alloy clamps is easily justified. Of course, 316 clamps could be used throughout any vessel.

A clamp marked “all stainless” probably refers to the band and screw. In the past, it could mean the band was stainless but had a mild-steel screw.

For especially large-diameter or particularly stiff or thick hose, a variation on the traditional worm-gear clamp may be required. T-bolt clamps utilize a conventional threaded machine-screw-type fastener coupled with a stainless hose-clamp band. This clamp can impart higher compression over a wider surface area (T-bolt clamps are typically wider than most traditional hose clamps).

As useful and rugged as T-bolt clamps are, they too have weaknesses. Because they rely on a stainless-steel stud and a stainless-steel nut, they are prone to thread galling. This phenomenon is typical for most heavily loaded stainless-steel fastener applications; it essentially amounts to micro welding as a result of heat generated within the threads as they are tightened. This is easily prevented by lightly lubricating the threads before clamps are installed (if this hasn’t already been done by the manufacturer).

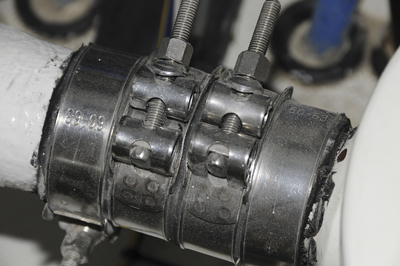

The spot-welded fold in this solid-band clamp is an ideal environment to entrap water, leading to crevice corrosion.

Another possible Achilles’ heel of these clamps is a function of the manufacturing process. The T-bolt is retained by the band by folding the band over and spot-welding it back to itself, creating a bight of metal, or an envelope of sorts to wrap around the T. While this yields a resilient retention method for the tightening mechanism, it also forms an area that can trap water, often leading to crevice corrosion (see “Power and Peril of Stainless Steel” to learn more about crevice corrosion). If used in routinely wet locations, such as shaft and rudder stuffing boxes, bilge pump plumbing, and other bilge applications, T-bolts are prone to crevice-corrosion-induced failure, which can be insidious. I’ve encountered shaft-stuffing-box T-bolt clamps that looked virtually pristine on the upper hemisphere of the hose, while the bottom 20° were so heavily corroded that the band had parted entirely; it was retained in place strictly by adhesion to the hose and applied no tension to maintain watertight integrity. If T-bolt clamps are used in this application, position the folds and welds in the hose’s upper half and fill their voids with a viscous corrosion inhibitor.

Avoid using folded-spot-weld clamps in areas continuously exposed to water, especially on stuffing boxes.

AWAB/NORMA created a T-bolt clamp that relies on interlocking rather than folded and spot-welded bands, thereby minimizing the water-trapping fold and its potential for corrosion and possible failure. These clamps are well suited to wet locations.

When selecting hose clamps, don’t skimp on this important corrosion-resistance element. Clamps, screw, and band must all be stainless steel, a minimum of 304 for “dry” applications and 316 for wet, with solid embossed-thread bands.

Beware: hose clamp material configurations and combinations can run a potentially confusing gamut, well beyond mild or stainless steel. They include a 300 series stainless-steel band with a zinc-plated mild-steel screw; 300 series stainless-steel band and a 410 series stainless screw; 300 series stainless band and screw; and 316 series stainless-steel band and screw.

Hose Clamp Installation

Among the most frequently asked questions about hose-clamp installation is the “requirement” for double clamps. While double clamps are undeniably desirable, they are required in only a few instances specified by whatever standards your project must satisfy.

Using two clamps when a barb can support only one often damages the hose. This hose could not be pushed any farther onto a stepped barb.

The ABYC (American Boat & Yacht Council) recommendations call for double clamps in only two locations: fuel-fill hoses and exhaust systems (my own guidelines add stuffing boxes to this list). Double clamps are required for some international boatbuilding guidelines, including those of ISO (International Organization for Standardization), which mandates double clamping of hoses on seacocks, in addition to other locations.

The most common double clamp misstep is the use of the second clamp in applications where it is not properly supported—for example, where its pressure cannot bear fully on the pipe-to-hose adapter (more on those in a moment) beneath it. This phenomenon is often the result of an overzealous installer who believes or may insist that two clamps are mandatory and without them failure is imminent. Ironically, that may have the opposite effect, causing damage to, or a premature failure of, the hose.

In locations other than those mentioned above, where they are required for ABYC compliance, and especially if a second clamp cannot properly and fully bear on the pipe-to-hose adapter without overlapping the first clamp, a single high-quality, all-stainless-steel, solid-band clamp should be used. Install clamps so that ¼“ (6.35mm) of hose is visible between the band and the hose end (and an estimated ¼“ between the end of the pipe-to-hose adapter and the clamp), and approximately ¼“ between any two clamps’ bands. In short, it’s critically important to confirm the length of the pipe-to-hose adapter under the hose before installing a clamp or clamps.

I’m often asked if, when two clamps are used, should the screws be installed 180° from each other, i.e., with the screwheads facing in opposite directions? Informed by my own testing, I don’t believe it matters. Clamps are designed to impart even pressure on a hose regardless of the screw’s position. If it makes you feel better installing them with this orientation, go for it; however, it’s more important that the screw be easily accessible for future torqueing.

How Tight?

Hose clamps should be tightened to their manufacturer-rated torque specifications, typically in inch-pounds. While I don’t expect installers to use a torque driver for every clamp (mini palm-size torque wrenches suitable for hose clamps are available), doing so periodically, especially on critical installations like fuel and raw-water systems, confirms the feel for just how much tension is required by the manufacturers to ensure a positive seal between the hose and pipe-to-hose adapter.

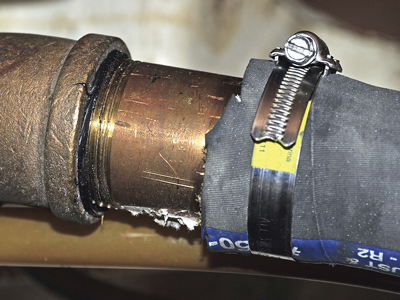

Except for fuelfill and exhaust applications, hoses should be

installed over barbed pipe-to-hose adapters, unlike this hose installed over a smooth pipe nipple—which should be avoided.

Most full-size solid-band hose clamps call for 30–50 in-lbs (34.6–57.6 kg-cm) of torque, which is easily achieved with a screwdriver, a ¼“-drive socket wrench, or proprietary hose clamp installation tool. As mentioned earlier, overtightening will damage the perforated clamp’s threads and the hose, and increases the likelihood of crevice corrosion through microcracking of the clamp’s band, especially the perforated ones. Clamps often require less tension than is believed, which is why the occasional torque-wrench test is beneficial. By the way, proprietary hose-clamp drivers are among the more useful tools if you regularly install these clamps; their flexible shank eases access to hard-to-reach clamps, and the ergonomic wide-grip handle allows the installer to impart the right torque without straining.

I’ve used the term pipe-to-hose adapter (PTH) several times. A PTH is a device that looks like a short length of pipe, with an important difference: the area over which the hose is installed is neither smooth nor threaded but made up of a series of barbs—sort of wedge-shaped bumps with one tapered and one squared edge, which secure the hose when clamped. An alternative, a beaded pipe, has a slightly oversized and squared-off lip at its end (common on raw-water pumps). Often, installers will substitute a pipe nipple for a PTH adapter. Pipe nipples have a smooth and a threaded section, but they do not have barbs or a beaded end. The smooth section provides insufficient grip for the hose, and the helical thread creates a path for fluid leakage. Even with the threaded section cut off, the remaining smooth pipe section is too slippery for a reliable hose interface. These deficiencies make the pipe nipple an inappropriate and unreliable method of terminating any hose. Incidentally, for ABYC compliance, fuel-fill and exhaust PTH adapters may be smooth, unbarbed surfaces, but they may not be threaded at the hose interface area, i.e., pipe nipples may not be used.

Sizing Hose Clamps Right

Hose clamps come in an assortment of diameters, and a pet peeve of mine is clamps that are too large for the application. While an oversized clamp may do the job, it invariably leaves a long, potentially sharp “tail” (clamp manufacturers call this an “overlap”), just waiting to scrape a forearm or finger. If this occurs in a bilge, under a galley or head sink, or, worse, in a sanitation plumbing area, the potential rises for an injury to become infected (all marine-service-yard professionals, professional crew, and surveyors should have up-to-date tetanus vaccinations, which are typically good for 10 years).

On clamps in high-traffic areas, proprietary silicone hose-clamp-tail finishers help prevent injury.

In addition to using the right size clamp for the job, you can go a step further by either slightly bending any remaining tail down into the tensioned portion of the band or by installing a proprietary clamp finisher or “jacket.” The finisher safely envelops the sharp end of the clamp band and is especially useful in high-traffic areas including the galley, and in head sink installations and bilges. Avoid the jackets made of hard materials such as PVC, as they are easily dislodged from clamps. And beware that many are sized so that they will slip between the strainer slots of submersible bilge pumps, where they can clog rotors. Choose silicone jackets, which are especially supple and sticky to adhere tenaciously to the clamp.

The same caveat holds true for the exposed portion of the shank on T-bolt clamps. While less sharp, these still present an injury hazard and are a nuisance, as they tend to catch clothing and gear. These can be made safe with proprietary caps or a short section of appropriate-diameter hose to cover them.

here, a section of appropriately sized hose.

Employing an oversized T-bolt clamp runs the risk of it “two blocking,” or running out of adjustment before applying enough tension to the hose. If both ends of the clamp connected via the bolt make contact with each other, with no room for adjustment, the clamp is oversized and could allow the hose to separate from its adapter. This failing is especially insidious because the installer feels tension building as the nut is being tightened, creating the impression the clamp is compressing the hose when in fact it’s simply running out of adjustment.

Stainless Steel 304 Hose Clamps

Does It Matter How the Hose Is Attached?

T-bolt clamps have a relatively short adjustment range, so they are often oversized. This clamp is two-blocked with no more

room for adjustment; it feels tight but may not be adequately compressing the hose.

During an engineroom inspection aboard a vessel undergoing sea trials, I experienced just how flawed a pipe nipple as a PTH adapter can be. With the propulsion engine operating at full power, I went through the engineroom with an infrared pyrometer to check the temperature of various components. After I had completed my rounds, I stepped out of the space and closed the hatch. Even through my hearing-protection muffs, I heard a loud whoosh. With my hand still on the handle, I instinctively reopened the hatch, and a cloud of steam billowed through the opening. I told the operator to shut down the engine and reentered the space to find the source of the steam: a failed coolant hose or, more precisely, a failed coolant PTH adapter connection. The vessel was equipped with a keel cooler plumbed to the engine via a set of 2“-inside-diameter (51mm) hoses terminating at the engine using a set of pipe nipples. Despite the hose being double clamped, it had slipped off the threaded nipple, spewing the entire contents of the cooling system, roughly 10 gal (37.85 l) of 200°F (99.3°C) coolant, around the engineroom. Just moments before, I was standing in front of that engine taking temperature readings of the expansion tank. Had the hose released then, I would have been severely burned.

When it comes to selecting and installing hose clamps, take no chances. Use only the highest quality, most durable, properly torqued clamps, and ensure that they are installed over PTH adapters. If the adapter will accommodate two clamps, double up. And if double clamps are required for ABYC or ISO compliance, then by all means install twin clamps.

About the Author: For many years a full-service yard manager, Steve now works with boat builders and owners and others in the industry as Steve D’Antonio Marine Consulting. He is an ABYC-certified Master Technician and sits on that organization’s Engine and Powertrain, Hull Piping, and Electrical Project Technical Committees. He is also technical editor of Professional BoatBuilder.

Sidebar: The Magnetism Test

A magnet test can distinguish austenitic (marine) grades of stainless steel from others but is not entirely reliable when applied to fasteners. If it‘s magnetic, it is less corrosion resistant.

Generally speaking, austenitic or marine-class corrosion-resistant 300 series stainless steel is nonmagnetic, while the nonmarine, and more corrosion prone, martensitic and ferritic classes, are magnetic. Therefore, with some exceptions (such as duplex stainless steel, which is highly corrosion resistant and magnetic), it’s usually possible to identify nonmarine grades of stainless steel using a magnet.

Fasteners, however, present a challenge. Of the five stainless classes, the four mentioned above are defined by the metal’s microstructure, with the fifth—precipitation-hardened—defined by its heat treatment. Microstructure determines the magnetism of these alloys. Cold-working, a phenomenon that occurs when rolling screw threads and stamping screwheads, changes the microstructure of the stainless steel from austenitic to martensitic. This process is called martensitic stress-induced transformation (MSIT). As a result of cold-working and/or slow-cooling, some portion of the austenite structure is changed to martensite, making the fastener slightly magnetic.

Fasteners are made from coils of wire drawn, formed, rolled, and stamped to make their various parts. In the process, a highly corrosion-resistant austenite is transformed into a less resistant austenite/martensite stainless alloy. This phenomenon is not unique to hose clamp screws; it applies to all stainless steel fasteners. It can be mitigated to some degree by cutting rather than rolling the threads, sacrificing some strength in the process, or by annealing after cold-working the metal. Therefore, it’s not unusual to find “all-stainless” hose clamps with magnetic screws; this does not necessarily mean they are made of mild steel and thus highly rust prone. While it’s not necessarily a scientific distinction, it’s possible to make a practical differentiation: typically, martensitic stainless steel is only mildly magnetic, while a common mild-steel fastener is highly magnetic.

Sidebar: Hose Clamp History

This drawing, from Knut Edwin Bergström’s 1949 patent application in the United States, is for a worm-gear hose clamp, likely an advance over his original 1896 patent.

Ask any Briton if he or she has a hose clamp, and you’ll likely get a quizzical look followed by, “Oh, you mean a Jubilee Clip?” In this case, I’d say their term for this ubiquitous bit of hardware takes precedence over our own more descriptive name; after all, one of their own played a large part in the hose clamp’s modern-day popularity. But the history of the hose clamp is long and storied and starts in Sweden.

The First Patent

The first patent for a hose clamp as we know it was granted by the Swedish Patent Office to inventor Knut Edwin Bergström, in 1896. Shortly thereafter, Bergström founded Allmänna Brandredskapsaffären E. Bergström & Co., later known as ABA, a manufacturer of fire-fighting equipment. Bergström invented, among other products, a hand-operated fire engine that utilized flexible metal tubing instead of a rubber hose, along with mechanical ladders and special rescue ropes. In 1918 Bergström was honored by the royal decree that only the ABA hose clamp should be used as the “standard clamp” for fire hoses across Sweden.

To expand production, ABA made its first acquisition in 1926, taking over Nya AB Henricson’s Motor und Sprutfabrik, a competing firefighting equipment manufacturer. The chance for Bergström’s hose clamp to achieve wide acceptance came in 1932, when the Norwegian company O.J. Dahl became aware of ABA. The sole agents for Northern Europe, they were impressed by ABA’s new clamps, which now included a worm-drive, and thereafter widely distributed the product throughout their territory.

In 1950 ABA acquired AB Telesigna—a young Swedish manufacturer of electronic watches, automatic fire alarms, control systems for fireproof doors, and the first car phones—transforming ABA into the ABA Group. Around this time, Knut Edwin Bergström handed over the reins to his son, Erik Bergström, who restructured the company to focus more on its international orientation with an emphasis on manufacturing ABA hose clamps.

With increasing postwar industrialization, specifically automobile and aviation production, the demand for hose clamps continued to grow. By 1963 ABA was producing 2.5 million clamps per year, and Erik Bergström expanded the company’s facility in Vattholma Bruk in several stages. Employees were still hand-building clamps one at a time, but by the early ’70s, ABA’s engineers were introducing the first semi-automatic clamp-manufacturing machines, which gradually increased production. Erik Bergström retired, and from 1972 through 1986 ABA was jointly owned by his sons Tor, Jan, and Nils, the third generation of Bergströms to lead the company. In 1986 Nils acquired his brothers’ shares, and became managing director.

In 1990 ABA once again merged, this time with the Swedish firm Anderstorps Werkstads AB, or AWAB, another respected hose-clamp brand familiar to boatbuilders around the world. Subsequent to the merger, production at the new ABA Group moved into AWAB’s former plant in Anderstorp, where bands for clamps were manufactured and AWAB clamps were assembled. Growth also continued abroad, with the addition of a 10,000-sq-ft (929m2) plant in the United States in 1992, which closed in 2008. The company now maintains a 74,000-sq-ft (6,875m2) domestic facility for U.S. distribution and manufacturing. Plants were also set up in Belgium and The Netherlands around this time.

Founded in 1949 by Ove Skafte Rasmussen, son of a Danish industrialist, the West German hardware manufacturer Rasmussen GmbH offered a tilting bicycle seat, called NORMA. Designed to make riding uphill more comfortable, it was not a commercial success, so the fledgling company reverted to another product—a hose clamp, also branded NORMA, which became very popular with European automotive and industrial equipment manufacturers. The company remained family owned until 2006, when it was purchased by and merged with ABA. Now collectively “Norma Group,” it is one of the world’s largest hose clamp manufacturers, with brands including, in addition to ABA, Breeze (the U.S. manufacturer that pioneered the perforated worm-drive-band clamp, familiar to the North American marine industry), Connectors, Serflex, Serratub, Terry, and Torca.

The “Jubilee Clip”

The first worm-gear hose clamp is attributed to Royal Navy Engineer Lieutenant-Commander Lumley Robinson,

who created the Jubilee Clip in 1921 in his neighbor’s garage.

The debut of the worm-gear hose clamp is attributable to the efforts of former Royal Navy Engineer Lieutenant-Commander Lumley Robinson, born in 1877 in Leeds, the son of an engine fitter. After apprenticing at John Fowler and Company, manufacturer of tractors, steamrollers, and locomotives, Robinson joined the Royal Navy as an engineroom mechanic. He was eventually promoted to warrant officer, retiring after 20 years as a Lieutenant-Commander. During WWI, while serving aboard the Cressy-class armored cruiser HMS Aboukir, his ship (along with two sisterships) was torpedoed by a German U-boat and sank in the North Sea in September 1914. He survived more than eight hours in frigid waters while awaiting rescue.

From his apprenticeship through his naval career, Robinson was surrounded by engines, steam propulsion, gears, and plumbing systems, and he often pondered how hoses—which were becoming ever more popular with the advent and rapid growth of the internal-combustion engine and hydraulics—might be connected to rigid pipes. Shortly after retiring from the navy, he considered this more seriously, often frequenting a friend’s garage shop equipped with a lathe. After some experimentation, he arrived at a design he christened the “Jubilee Clip,” samples of which he took to London to sell. His wife, Emily Boyd or “EB,” had such faith in the innovation that she suggested they mortgage their home to purchase the first lot of steel for manufacturing it. Swift sales made this unnecessary, and capital quickly became available. The U.K. patent office granted Lumley Robinson a patent for his worm-drive hose clip in April 1921.

Details from Robinson’s original Jubilee Clip patent illustrate the adjustment screw’s housing and the embossed pattern on the clamp band that engages the threads.

By the eve of WWII, more than half a million clips were being manufactured weekly. Lieut-Commander Robinson died at the age of 62, just a month before the outbreak of the war, a conflict in which his invention would play a pivotal role. Shortly after hostilities started, representatives of the British War Ministry arrived at the offices of L. Robinson and Co. to take over the firm in the name of the war effort. Robinson’s widow, EB, flatly rejected their “offer.” She changed her last name to Lumley-Robinson, and took the reins, running the firm throughout the war. After the war, her youngest son, John Lumley-Robinson, joined her and eventually took over the company. As a tribute to Jubilee Clip’s contributions, during the Battle of Britain EB ceremoniously presented a Spitfire fighter to the RAF, appropriately named The Robinson Fighter. The Jubilee Clip was found in every theater, in the air, on land, on and under the sea, with the slogan “There’s never a drip with a Jubilee Clip.”

On April 1,1948, the firm was incorporated as L. Robinson & Co. (Gillingham) Ltd. Other manufacturing entities were added over time, including Jubilee Components Ltd and Jubilee Clips Ltd, which were established to take on manufacturing, along with L. Robinson & Co. (Plating) Ltd, an electroplating firm established in 1968. In 2008, the group acquired a new property in the same town where the original Jubilee Clips were made, and where all U.K. manufacturing of various L. Robinson & Co. products was consolidated. Today, Robinson’s great-grandson Ian Jennings (who I had the pleasure of meeting at several Marine Equipment Trade Shows in Amsterdam) represents, as Joint Managing Director, the fourth generation of the family, working alongside his father, John Jennings. The timeless simplicity of the clip’s design is evidenced by how little it has changed from the original patent submission.

No one quite knows where the “Jubilee” in Jubilee Clip name originates. One popular urban myth has it that it was coined by Lieut-Commander Robinson as he walked back and forth to work across the Jubilee Bridge in Gillingham. While there are Silver and Golden Jubilee bridges in the U.K., there is no Jubilee Bridge in Gillingham, and thus it remains a mystery.

Next year, Lieut-Commander Robinson’s Jubilee Clip will celebrate its centenary.

By all rights, ABA takes the prize for the first (Swedish) patented hose clamp, a screw and nut design, while Robinson’s Jubilee Clip holds the first U.K. patent: the creation of the worm-drive clamp, a product now ubiquitous and manufactured by many companies, including NORMA, by the hundreds of thousands.