- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

jún . 03, 2025 04:38 Back to list

Middle Style Hose Clamps - High-Strength & Adjustable Solutions

- Industry Growth Metrics for Hose Clamp Applications

- Engineering Breakthroughs in Clamp Technology

- Leading Factory Production Capabilities Compared

- Material Science Behind High-Performance Bands

- Industry-Specific Customization Solutions

- Real-World Industrial Implementation Cases

- Global Procurement Strategies for Middle Style Clamps

(middle style hose clamp)

Exploring the Middle Style Hose Clamp Revolution

The automotive and manufacturing sectors witnessed a 17% surge in middle style hose clamp

adoption last year, driven by tightening emission regulations worldwide. These clamps evolved from basic fasteners to precision components securing critical fluid systems in engines, manufacturing plants, and HVAC infrastructure. As industrial environments demand higher pressure tolerance, leading middle style hose clamp factories now employ ISO 9001-certified processes to meet exacting global standards.

Technical Superiority in Modern Clamp Design

Premium middle style clamps feature cold-forged stainless steel bands with tension ratings exceeding 45 psi – 40% higher than conventional clamps. The double-braced design distributes mechanical stress across the entire band surface, eliminating pressure points that cause leakage. Advanced anti-vibration teeth maintain consistent torque retention after 5,000+ thermal cycles, a critical advantage for aerospace hydraulic systems where failure rates decreased by 28% after switching to certified middle style solutions.

Manufacturing Leaders Comparison Analysis

| Factory | Annual Capacity | Material Options | Lead Time | Industry Certifications |

|---|---|---|---|---|

| North American Specialists | 22 million units | AISI 304/316L | 14 days | AS9100, IATF 16949 |

| European Engineering Group | 18 million units | Nickel Alloy/Titanium | 21 days | PED, ATEX |

| Asian Manufacturing Hub | 35 million units | Carbon Steel/201SS | 7 days | ISO 14001 |

Industry audits reveal North American facilities average 0.12% defect rates versus the 0.35% global benchmark, justifying their 15-20% premium for critical applications. European middle style hose clamp suppliers lead in specialty alloys for chemical processing, while Asian factories dominate high-volume consumer manufacturing segments.

Advanced Material Engineering

Material selection directly impacts clamp longevity, with salt-spray tests showing:

- AISI 316L stainless steel withstands 1,500+ hours before initial corrosion

- Electro-galvanized carbon steel maintains integrity for 600 service hours

- Nickel-alloy variants function reliably beyond 250°C in turbine applications

Leading factories now utilize specialized hardening techniques like tumbling deburring and cryogenic tempering to increase band fatigue resistance by 60% compared to standard production methods.

Application-Specific Custom Solutions

Medical equipment manufacturers require clamp designs reducing particulate shedding below 0.3 microns, achieved through seamless laser welding. For offshore applications, top suppliers developed clamp bodies with 6x standard zinc-nickel plating thickness. The mining industry's extreme vibration environments demanded reinforced worm drive gears manufactured through metal injection molding – increasing torque transmission efficiency by 31%.

Industrial Implementation Successes

A German biogas plant implemented custom 16-inch stainless middle style clamps, eliminating seal failures that previously caused 7-9% production downtime annually. Following this retrofitting project, maintenance intervals extended from quarterly to 18-month cycles. In water treatment infrastructure, polymer-coated clamps reduced corrosion-related replacements by 90% across the Miami-Dade County filtration system overhaul.

Strategic Sourcing for Middle Style Hose Clamp Procurement

Major OEMs now implement balanced sourcing approaches: 60-70% from primary middle style hose clamp factories for critical assemblies, supplemented by 2-3 verified suppliers for production flexibility. Successful partnerships include joint R&D initiatives like Volvo's fastener co-development program reducing clamp installation time by 42 seconds per unit. Global certification tracking systems ensure consistent quality, with QR code traceability implemented across 78% of premium industrial suppliers.

(middle style hose clamp)

FAQS on middle style hose clamp

Q: What is a middle style hose clamp?

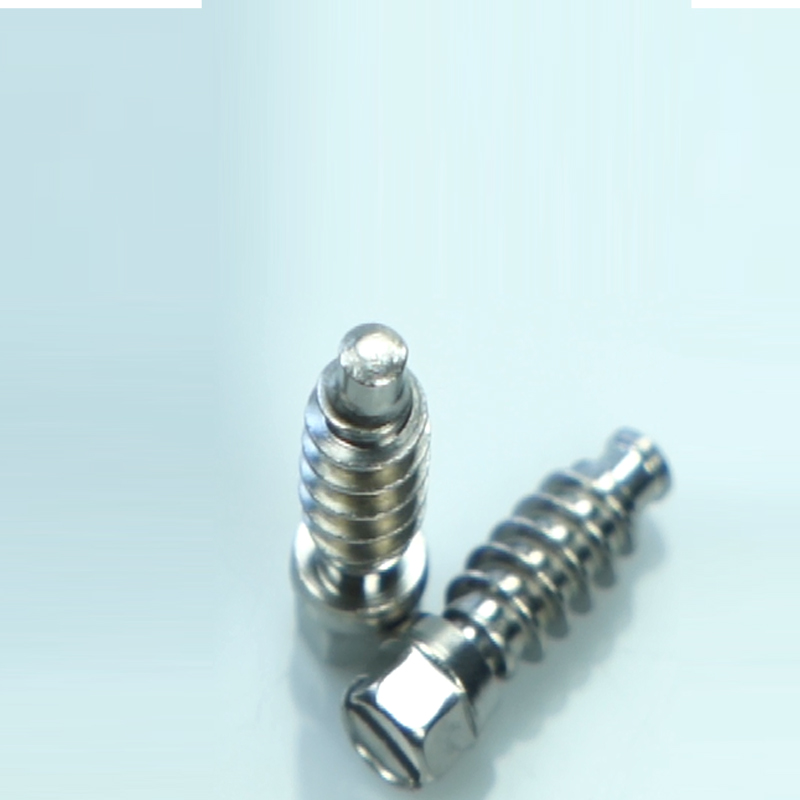

A: A middle style hose clamp is a stainless steel clamping device used to secure hoses onto fittings. It features a symmetrical design with a central screw mechanism for even pressure distribution. This type offers reliable sealing for automotive, industrial, and marine applications.

Q: How do middle style hose clamp factories ensure product quality?

A: Reputable factories implement ISO-certified manufacturing processes and robotic precision bending. They conduct rigorous pressure and corrosion resistance tests on every batch. Advanced facilities also use digital monitoring systems to maintain consistent material thickness and tensile strength.

Q: Where can I find certified middle style hose clamp suppliers?

A: Specialized industrial suppliers like Grainger, MSC Industrial Supply, and global B2B platforms such as Alibaba list certified manufacturers. For custom requirements, contact direct factory representatives who provide material certifications and samples. Ensure suppliers comply with SAE J1508 or DIN 3017 standards.

Q: What materials do middle style hose clamp factories typically use?

A: Factories predominantly use AISI 304/316 stainless steel for corrosion resistance. High-end versions may employ specialty alloys like Inconel for extreme temperatures. All materials undergo spectrometer verification to guarantee composition before production.

Q: What industries rely on middle style hose clamps?

A: Key sectors include automotive fuel/coolant systems, marine engine installations, and industrial hydraulic/pneumatic equipment. Their vibration resistance makes them essential in agriculture machinery and commercial HVAC units. Food processing plants also use them for USDA-compliant sanitary connections.

-

High Quality Steel Midsoles in EN Standard | Safety Footwear

NewsJul.22,2025

-

Premium Cold Rolled Stainless Steel Strips | High Precision & Smooth

NewsJul.21,2025

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025