- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

දෙසැ. . 24, 2024 16:52 Back to list

marine fuel hose clamps factory

The Importance of Marine Fuel Hose Clamps An Insight into Their Manufacturing

In the maritime industry, where the safety and efficiency of operations are paramount, the role of marine fuel hose clamps cannot be overstated. These seemingly simple yet crucial components ensure that fuel lines are securely fastened, preventing leaks that could lead to catastrophic consequences at sea. As a manufacturing industry, the production of marine fuel hose clamps requires precision engineering, high-quality materials, and strict adherence to safety standards.

Understanding Marine Fuel Hose Clamps

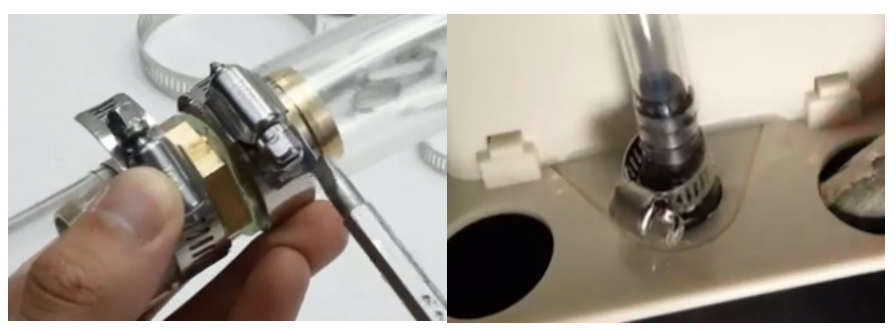

Marine fuel hose clamps are specially designed to secure fuel hoses used in various marine applications. By holding the hoses tightly in place, they prevent fuel leaks that could endanger vessels and their crews. The types of clamps used in marine environments must withstand harsh conditions, including exposure to saltwater, extreme temperatures, and pressure from the fuel system.

These clamps come in various designs, including worm gear clamps, spring clamps, and band clamps, each offering distinct advantages based on the application. Worm gear clamps, for example, provide a high level of clamping force and are adjustable, making them versatile for different hose diameters. Spring clamps, on the other hand, offer a quick-release mechanism, allowing for easy installation and removal.

Manufacturing Process

The manufacturing of marine fuel hose clamps involves several key steps, each critical to ensuring the final product's quality and reliability.

1. Material Selection The first step in the manufacturing process is selecting appropriate materials. Stainless steel is commonly used due to its corrosion resistance and strength, which are vital for maritime applications. Additionally, some clamps may feature plastic components that resist degradation in salty environments.

marine fuel hose clamps factory

2. Design and Engineering Next, engineers utilize computer-aided design (CAD) software to create precise designs for the clamps. This stage involves meticulous calculations to ensure that the clamps will fit various hose sizes and can withstand the forces they will encounter in marine conditions.

3. Production After finalizing the design, the production process begins. This may involve processes like stamping, machining, or casting, depending on the clamp's complexity and requirements. Automated machinery is often employed to enhance precision and efficiency while reducing production costs.

4. Quality Control Once manufactured, each clamp undergoes rigorous quality control testing. This can include weight testing, pressure testing, and corrosion resistance tests to ensure they meet industry standards. Compliance with international standards, such as those set by the American Boat and Yacht Council (ABYC) or the International Organization for Standardization (ISO), is crucial for maintaining market credibility.

5. Packaging and Distribution Finally, after passing quality assurance tests, the clamps are packaged and prepared for distribution. Proper packaging is essential to protect the clamps from damage during transportation and storage.

The Role of Technology

Modern technology has transformed the manufacturing of marine fuel hose clamps. Computer numerical control (CNC) machines, advanced welding techniques, and 3D printing are just a few examples of how technology enhances production efficiency and customizability. Manufacturers can now produce smaller batches of clamps tailored to specific customer needs without incurring significant costs.

Conclusion

Marine fuel hose clamps are essential components in ensuring the safe and efficient operation of vessels. Their manufacturing involves a complex process that reflects the importance of quality and durability. As the maritime industry continues to evolve, so too will the technology and processes used in producing these vital components. For boat builders and operators, investing in high-quality marine fuel hose clamps is not just a matter of compliance but a commitment to safety and reliability on the open water.

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025

-

Mini Hose Clamp Manufacturer & Supplier Precision Hose Clamps Mini Clamp Factory

NewsJul.07,2025