- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 09, 2024 07:49 Back to list

Durable and Reliable Solutions for Crimped Hose Clamps in Various Applications

Understanding Crimped Hose Clamps A Comprehensive Overview

In the world of mechanical engineering and fluid management, hose clamps serve as unsung heroes. Among the various types available, crimped hose clamps stand out for their reliability and effectiveness. Their unique design and installation method make them indispensable across a wide range of applications, from automotive to industrial settings. This article delves into the characteristics, advantages, and applications of crimped hose clamps to shed light on their importance in fluid management systems.

What are Crimped Hose Clamps?

Crimped hose clamps are devices used to securely fasten hoses to fittings, preventing leaks and ensuring a solid connection. Unlike traditional screw-type clamps, crimped clamps are made by deforming a metal band around the hose's outer surface. This metallurgical process, called crimping, creates a tight seal by distributing pressure evenly around the hose, which is critical for maintaining flow without leakage.

Advantages of Crimped Hose Clamps

1. Tight Seal Due to the crimping process, these clamps can create a tighter seal compared to other types. This makes them especially useful in high-pressure environments where even the smallest leak could lead to significant consequences.

2. Durability Crimped hose clamps are made from high-quality materials, often stainless steel or other corrosion-resistant metals. This ensures that they withstand harsh environmental conditions, making them suitable for outdoor applications and industries requiring sanitary conditions.

3. Ease of Installation Although installation of crimped hose clamps can be more specialized than screw clamps, they offer a robust option that does not require ongoing adjustments. Once crimped, they remain secure without the need for periodic tightening, which is an advantage in many settings.

4. Vibration Resistance In applications where vibrations are prevalent—such as in automotive or aerospace sectors—crimped hose clamps excel. Their design minimizes the risk of loosening over time, ensuring that connections remain intact, reducing the risk of failure.

crimped hose clamps

5. Cost-Effectiveness While the initial setup may require special crimping tools, the long-term savings are evident. Their durability and reliability reduce maintenance efforts and potential downtime caused by leaks, making them an economical choice for many industrial applications.

Common Applications

Crimped hose clamps find their utility across various sectors

- Automotive Industry In vehicles, hose clamps are vital for securing coolant hoses, fuel lines, and brake lines. Crimped clamps are preferred for their ability to handle high pressures and temperatures, ensuring that essential fluids remain contained without leaks.

- Hydraulic Systems In hydraulic machinery, maintaining optimal pressure and fluid integrity is crucial. Crimped hose clamps provide reliable connections for hydraulic hoses, thus playing a critical role in the functionality and safety of hydraulic systems.

- Food and Beverage Processing Sanitary applications often require clamps that adhere to strict hygiene standards. Crimped hose clamps, often made from stainless steel, are ideal for securing hoses in processes involving food and beverages, where contamination must be avoided.

- Construction and Manufacturing In construction machinery and manufacturing processes, hose clamps facilitate fluid transfer between various components. Crimped clamps ensure that these connections are reliably secure, minimizing the risk of fluid loss which could impact work efficiency.

Conclusion

Crimped hose clamps, albeit less visible to most, play a critical role in a wide array of industries. Their design and capability to deliver a strong, leak-proof seal make them the preferred choice in applications demanding high reliability. Whether in a car, a factory, or a restaurant, understanding the functionality and benefits of crimped hose clamps helps industry professionals make informed decisions about their fluid management systems. As we continue to innovate and expand applications for various technologies, the importance of robust components like crimped hose clamps will undoubtedly remain a key factor in ensuring safety, efficiency, and effectiveness across the board.

-

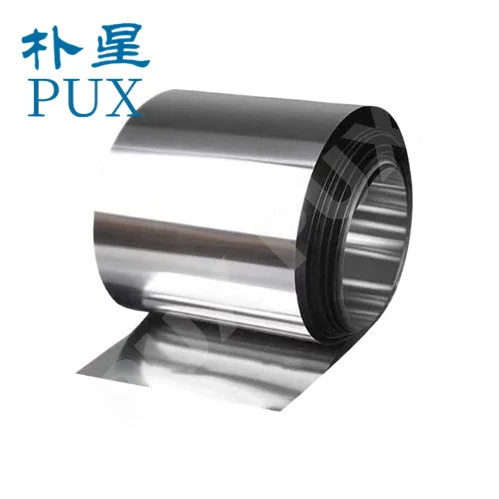

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025