- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 10, 2024 12:58 Back to list

Affordable Hose Clamps Available at Dollar General Stores Nationwide

The Significance of Hose Clamps in Dollar General Factories

Hose clamps, often overlooked in the vast realm of manufacturing, play a crucial role in the efficiency of operations within Dollar General factories. These seemingly simple tools are essential for securing hoses and pipes in various applications, from plumbing to automotive assembly. In a world increasingly reliant on efficient supply chains and robust production systems, understanding the importance of hose clamps and their application in Dollar General factories provides insight into the broader manufacturing landscape.

The Role of Hose Clamps

Hose clamps are devices used to attach and seal a hose onto a fitting, preventing any leakage of liquids or gases. They come in various designs, such as worm gear clamps, spring clamps, and wire clamps, each serving specific purposes depending on the requirements of the application. In a factory setting, particularly in Dollar General's operations where equipment reliability is paramount, hose clamps ensure that machinery functions smoothly without unexpected interruptions.

In Dollar General factories, hose clamps are extensively used in liquid handling and pneumatic systems, which are crucial for the production and distribution processes. Their primary purpose is to maintain tight seals that not only ensure the safe and efficient transportation of fluids but also contribute to maintaining optimal pressure levels within the systems. Any failure in this regard could lead to costly production downtimes and waste, underlining the significance of quality hose clamps in operations.

Quality and Standards

The choice of hose clamps in Dollar General factories is not taken lightly. Quality control standards are stringently upheld to ensure that the clamps can withstand the rigors of factory operations. The materials used in manufacturing hose clamps—commonly stainless steel or durable plastic—must fulfill specific strength and flexibility criteria. Dollar General’s commitment to quality translates into higher performance in their production lines, leading to reduced failure rates and longer maintenance intervals.

Cost Efficiency

hose clamp dollar general factories

One of the strategic advantages of employing hose clamps in manufacturing is their cost-effectiveness. The initial investment in high-quality clamps is outweighed by the long-term savings accrued from reduced maintenance costs and fewer production interruptions. Dollar General factories, characterized by their focus on value and efficiency, recognize that even small components like hose clamps can significantly impact the overall cost structure.

Moreover, if a hose clamp fails, it can lead to a domino effect of issues—product loss, increased labor costs for repairs, and potential hazards to worker safety. Thus, the importance of investing in quality hose clamps cannot be overstated. By ensuring that these components are reliable and robust, Dollar General can maintain a safer and more efficient factory environment.

The Impact on Productivity

In the fast-paced environment of Dollar General factories, where meeting demand is essential, productivity is a key factor. Loose or inadequate hose clamps can result in leaks and pressure drops, causing machinery to malfunction at critical times. This not only halts production but also strains workforce morale, as workers may face increased workloads to meet deadlines after unplanned downtimes.

By utilizing high-quality hose clamps, Dollar General ensures that production lines run smoothly, minimizing interruptions and maximizing output. This consistency reinforces the company’s reputation for reliability and quality in its operations, which benefits not only the factories themselves but also the customers who rely on timely product availability.

The Future of Hose Clamps in Manufacturing

As manufacturing technologies continue to evolve, it’s likely that hose clamp design and materials will also see advancements. Innovations such as smart hose clamps with integrated sensors could provide real-time monitoring capabilities, alerting factory personnel to potential issues before they escalate into significant problems. Dollar General, with its eye on the future, must remain adaptable and open to incorporating such innovations into its operations.

In conclusion, while hose clamps may seem like minor components in the grand scheme of manufacturing, their role in ensuring operational efficiency and reliability cannot be understated. For Dollar General factories, these devices are integral to maintaining production quality, enhancing safety, and optimizing costs. As the manufacturing landscape continues to evolve, so too will the importance of these seemingly simple yet critical components. Understanding this significance helps paint a clearer picture of the intricate workings of a successful manufacturing entity like Dollar General.

-

Large Stainless Steel Adjustable American Type Hose Clamp | Hebei Pux Alloy Technology Co., Ltd

NewsAug.05,2025

-

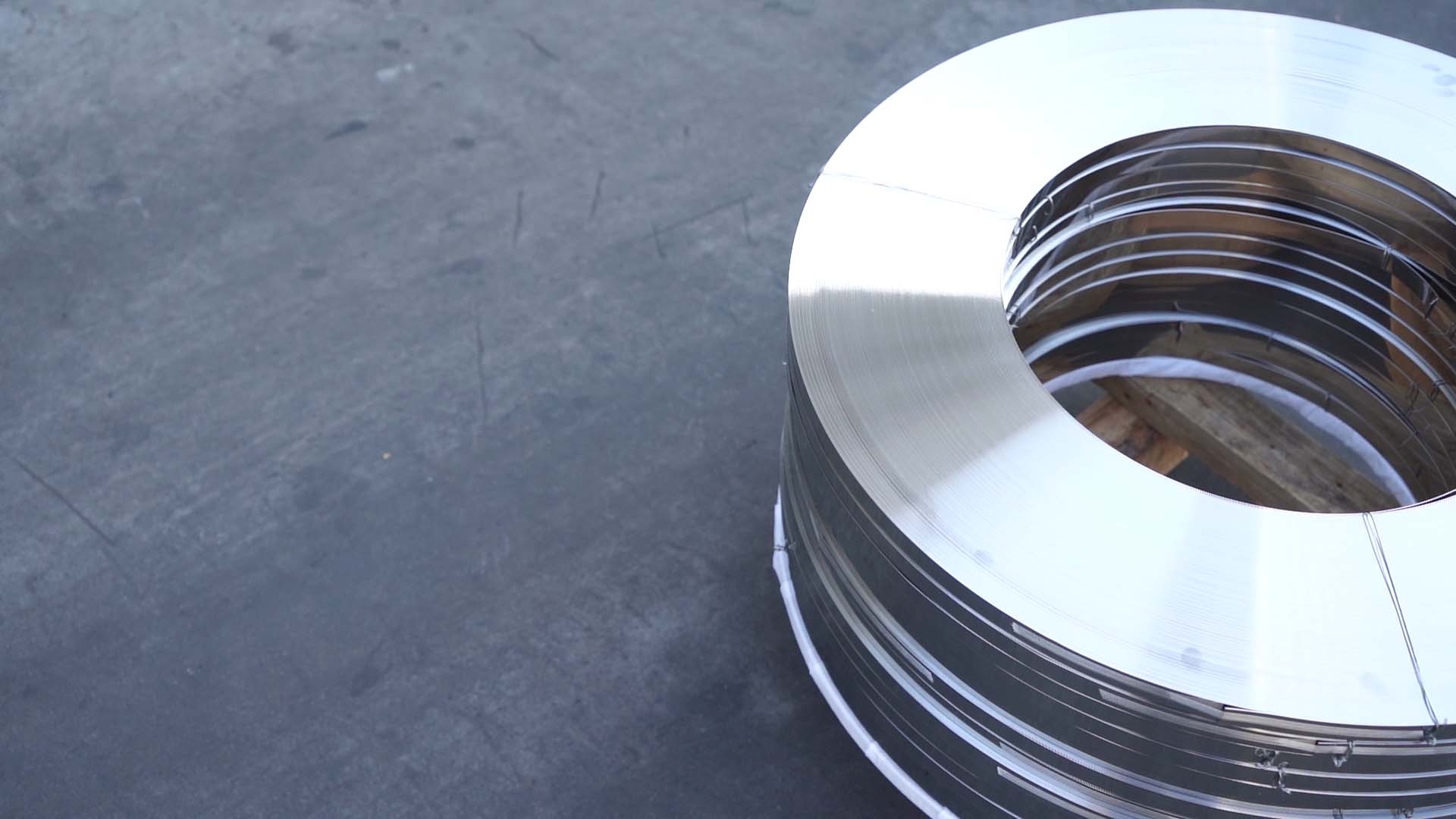

Quality 201 Stainless Steel Strip | Durable & Cost-Effective

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025