- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 14, 2025 05:14 Back to list

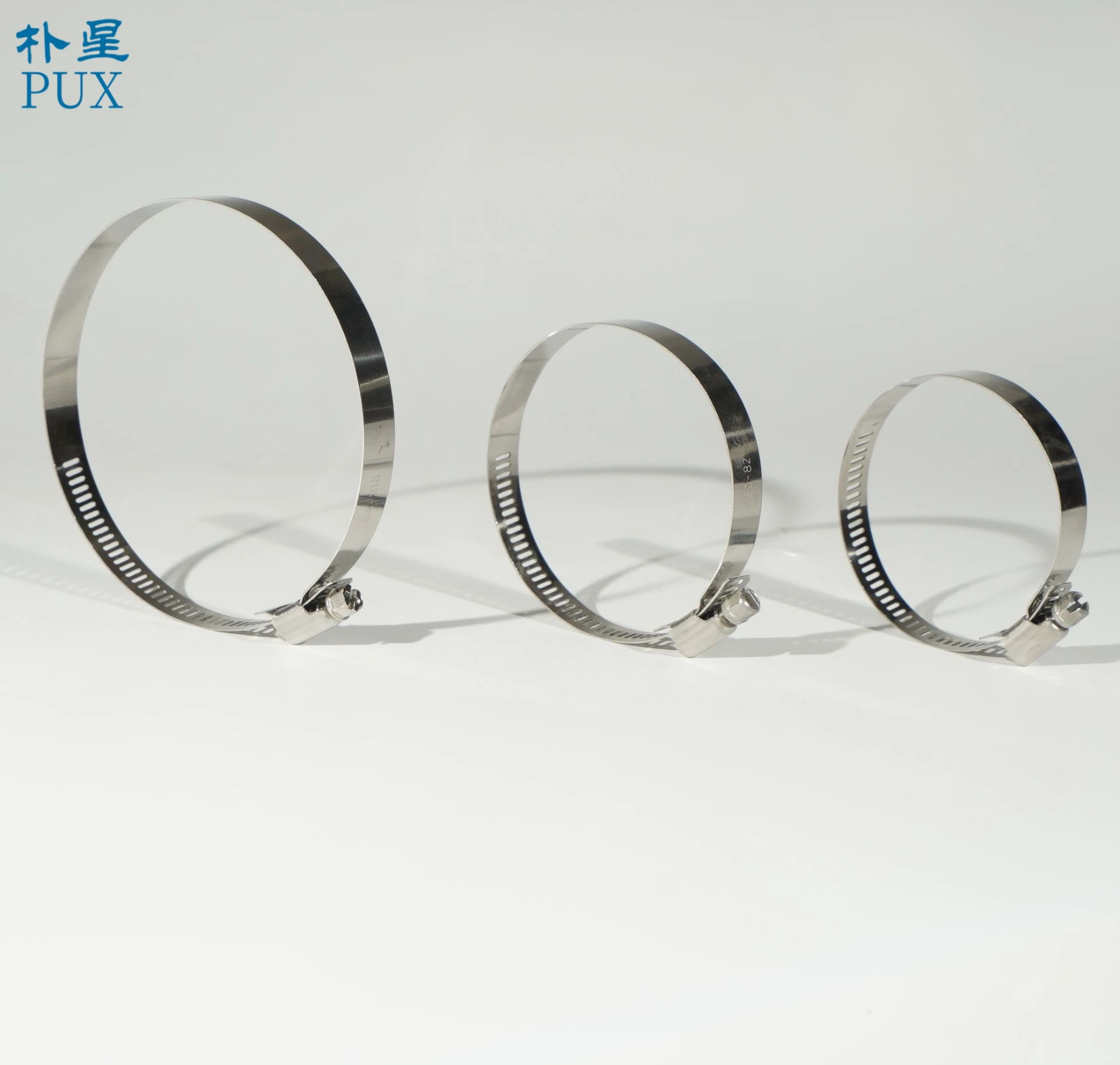

stainless steel hose clip

Engine hose clamps might seem like a small and insignificant component in the vast machinery of an automobile, yet their importance cannot be overstated. As a seasoned expert in automotive parts with decades of experience, I can attest to the critical role they play in maintaining the functionality and safety of a vehicle’s engine system. Engine hose clamps are pivotal in ensuring that the myriad of hoses running through an engine stay securely connected and leak-free, thus safeguarding the vehicle’s performance and longevity.

Moreover, regular maintenance checks are essential for maintaining the performance of engine hose clamps. Over time, a vehicle's vibrations and temperature fluctuations can cause clamps to loosen. Therefore, periodic inspections and adjustments are necessary to maintain a secure fit and to identify wear and tear that might necessitate replacement before failure occurs. The authority of engine hose clamps in the automotive field extends beyond their physical characteristics. In regulatory contexts, their reliability is often mandated by industry standards, such as those from the Society of Automotive Engineers (SAE). These standards ensure that the clamps meet specific performance and safety criteria, further underscoring their importance in vehicle maintenance and repair. In practice, real-world experiences have proven the impact of quality engine hose clamps on vehicle performance. For instance, a fleet of delivery trucks experiencing frequent engine overheating traced the issue back to substandard, poorly installed hose clamps that failed under pressure, leading to coolant leaks. Switching to high-quality stainless steel T-bolt clamps not only resolved the issue but also improved the reliability of the fleet, reducing downtime and maintenance costs. Trustworthiness in engine hose clamps is also derived from choosing products from reputable manufacturers known for their adherence to quality and durability standards. Brands that provide detailed specifications and comprehensive warranties tend to foster greater trust, as they demonstrate confidence in their products' performance under varying conditions. In conclusion, engine hose clamps, while seemingly minor, are indispensable components in ensuring an engine's integrity and efficiency. A deep understanding of their types, materials, installation, and maintenance requirements highlights their role in preserving the vehicle's performance. By prioritizing quality and reliability, users can ensure that these small but mighty parts continue to deliver optimum function, thereby fostering a vehicle's operational excellence and safety.

Moreover, regular maintenance checks are essential for maintaining the performance of engine hose clamps. Over time, a vehicle's vibrations and temperature fluctuations can cause clamps to loosen. Therefore, periodic inspections and adjustments are necessary to maintain a secure fit and to identify wear and tear that might necessitate replacement before failure occurs. The authority of engine hose clamps in the automotive field extends beyond their physical characteristics. In regulatory contexts, their reliability is often mandated by industry standards, such as those from the Society of Automotive Engineers (SAE). These standards ensure that the clamps meet specific performance and safety criteria, further underscoring their importance in vehicle maintenance and repair. In practice, real-world experiences have proven the impact of quality engine hose clamps on vehicle performance. For instance, a fleet of delivery trucks experiencing frequent engine overheating traced the issue back to substandard, poorly installed hose clamps that failed under pressure, leading to coolant leaks. Switching to high-quality stainless steel T-bolt clamps not only resolved the issue but also improved the reliability of the fleet, reducing downtime and maintenance costs. Trustworthiness in engine hose clamps is also derived from choosing products from reputable manufacturers known for their adherence to quality and durability standards. Brands that provide detailed specifications and comprehensive warranties tend to foster greater trust, as they demonstrate confidence in their products' performance under varying conditions. In conclusion, engine hose clamps, while seemingly minor, are indispensable components in ensuring an engine's integrity and efficiency. A deep understanding of their types, materials, installation, and maintenance requirements highlights their role in preserving the vehicle's performance. By prioritizing quality and reliability, users can ensure that these small but mighty parts continue to deliver optimum function, thereby fostering a vehicle's operational excellence and safety.

Share

Latest news

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025

-

Mini Hose Clamp Manufacturer & Supplier Precision Hose Clamps Mini Clamp Factory

NewsJul.07,2025