- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Дек . 03, 2024 17:19 Back to list

Brass Radiator Hose Clamps Manufacturers for Quality Automotive Solutions

Exploring the Brass Radiator Hose Clamps Factory Quality and Craftsmanship

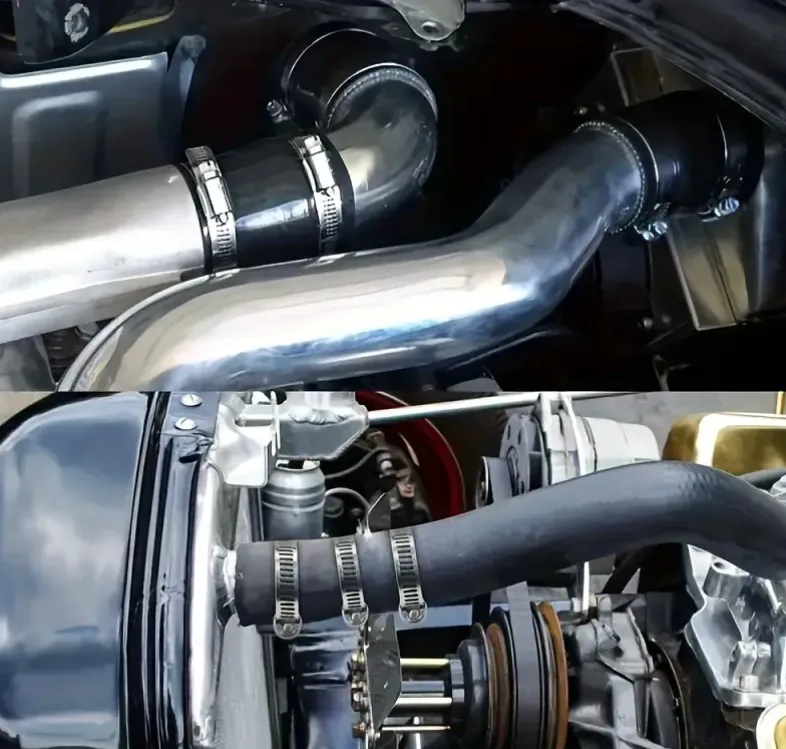

In the world of automotive engineering and maintenance, the importance of reliable and durable components cannot be overstated. One of the key elements that ensure the efficient functioning of cooling systems in vehicles is the radiator hose clamp. Among various materials used for manufacturing these clamps, brass has emerged as a favored choice due to its corrosion resistance, strength, and aesthetic appeal. This article delves into the intricacies of a brass radiator hose clamps factory, highlighting its production processes, quality standards, and the benefits of using brass clamps.

Understanding Radiator Hose Clamps

Radiator hose clamps are essential components that secure the hoses connected to the radiator, ensuring that coolant does not leak and that the engine operates at optimal temperatures. They come in various materials, but brass stands out for several reasons. Brass is an alloy primarily composed of copper and zinc, endowing it with excellent resistance to rust and corrosion. This makes brass clamps particularly suitable for high-temperature environments, such as those found in automotive applications.

The Manufacturing Process

A brass radiator hose clamps factory typically follows a meticulous manufacturing process to ensure that each product meets industry standards for quality and reliability. The journey begins with the selection of high-grade brass materials. The factory procures raw brass in the form of sheets, rods, or coils, which are then subjected to several processes including cutting, bending, and forming into the desired shapes.

1. Cutting and Shaping The first step in production involves cutting the brass into precise lengths needed for the clamps. Advanced CNC (Computer Numerical Control) machines are often employed to achieve exact measurements, reducing waste and improving efficiency.

2. Forming Once cut, the brass pieces are then formed into clamp shapes through processes such as stamping or forging. This step is critical, as it defines the physical characteristics of the clamps, including their strength and flexibility.

3. Surface Treatment To further enhance corrosion resistance, many manufacturers apply surface treatments such as nickel plating or anodization. These treatments not only improve resistance to elements but also provide a shiny, aesthetically pleasing finish.

4. Quality Control After the clamps are produced, they undergo rigorous quality control checks. This includes testing for strength, endurance, and resistance to corrosion. Factories often utilize advanced testing equipment to simulate real-world conditions, ensuring that each clamp can withstand the rigors of automotive use.

brass radiator hose clamps factory

5. Packaging and Distribution Once approved through quality control, the clamps are packaged for distribution. Factories often focus on eco-friendly packaging options, aligning with global sustainability trends.

Benefits of Brass Radiator Hose Clamps

Brass radiator hose clamps provide a multitude of benefits that make them an ideal choice for many applications

- Durability Brass is known for its strength and resilience. Unlike plastic or lesser-quality metal clamps, brass clamps can withstand hard impacts and extreme temperature variations.

- Corrosion Resistance One of the standout features of brass is its ability to resist corrosion, especially in environments where exposure to moisture and chemicals is prevalent.

- Aesthetic Appeal Brass clamps possess a distinctive golden hue that adds an element of visual appeal. For restorations or custom vehicles, brass components can enhance the overall aesthetic of the engine bay.

- Reliability A well-manufactured brass clamp offers peace of mind due to its reliability. Users can trust that these clamps will perform well over time, reducing the risk of breakdowns related to coolant leaks.

Conclusion

A brass radiator hose clamps factory embodies the convergence of quality craftsmanship, innovative manufacturing, and stringent testing protocols. By prioritizing the use of high-quality materials and advanced machinery, these factories ensure that they produce clamps that not only meet but exceed the expectations of both manufacturers and consumers. As the automotive industry continues to evolve, the demand for durable and reliable components like brass radiator hose clamps will remain essential, underpinning the efficient and safe operation of vehicles worldwide. Whether in high-performance cars or everyday vehicles, the choice of a brass clamp reflects an investment in quality that stands the test of time.

-

Steel Midsole with Stainless Steel – Durable, Lightweight Safety Solutions from Top Factories and Suppliers

NewsJun.24,2025

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025

-

Durable T Bolt Hose Clips Secure Leak-Proof Design

NewsJun.09,2025