- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Дек . 26, 2024 01:09 Back to list

9/16 hose clamp factories

The Essential Role of Hose Clamp Factories in Industrial and Automotive Applications

Hose clamps are unsung heroes in a myriad of applications, providing essential functionality in various industries, particularly in automotive, construction, and manufacturing sectors. Among the diverse range of hose clamps produced globally, the 9/16 size is notable due to its wide applicability and versatility. Factories dedicated to manufacturing these hose clamps play an integral role in ensuring quality, reliability, and performance across different sectors.

Understanding Hose Clamps

Hose clamps, sometimes referred to as hose clips, are devices designed to attach and seal hoses onto fittings such as barbs, nozzles, and pipes. They are essential for preventing leaks in fluid and gas transfer systems. The 9/16 hose clamp is commonly used due to its compatibility with various hose diameters, particularly in automotive applications where hoses transport fluids such as coolant, oil, and fuel.

These clamps are typically made from durable materials like stainless steel, galvanized steel, or plastic, each selected based on the specific requirements of the application. The effectiveness of a hose clamp can significantly affect the overall performance and safety of a system, making quality manufacturing a critical factor.

The Manufacturing Process

Hose clamp factories employ advanced manufacturing processes to produce high-quality clamps that meet industry standards. The production begins with sourcing raw materials, which must possess the right mechanical properties to withstand pressure and temperature variations.

Once the materials are procured, the manufacturing process involves several key steps

1. Cutting Raw materials are cut into appropriate lengths, preparing them for shaping. 2. Forming The cut materials are then shaped into the desired configuration, usually through bending and rolling processes. This step is crucial for achieving the correct diameter and ensuring a proper fit over the hoses.

3. Assembly In many cases, hose clamps consist of multiple components, including a band, housing, and screw. These parts must be assembled accurately to ensure the clamp functions effectively.

9/16 hose clamp factories

4. Finishing The products undergo various finishing processes, such as coating to enhance corrosion resistance or polishing for aesthetic appeal. Quality control checks are also performed at this stage to identify any defects.

5. Testing Before reaching the market, hose clamps are rigorously tested for strength, durability, and performance under pressure. This testing is vital to ensure that each product can withstand real-world conditions.

Importance of Quality Control

In hose clamp manufacturing, quality control is paramount. Factories often implement robust quality management systems to ensure that every clamp produced meets the required specifications. Any subpar product can lead to failures in the applications they are used in, potentially causing damaging leaks or catastrophic failures in critical systems.

Regular auditing, compliance with international standards, and adherence to customer specifications are integral components of quality assurance. Additionally, many factories are increasingly adopting automation and advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining, which enhance precision and consistency in production.

The Impact on Industries

The production of 9/16 hose clamps has a cascading effect across several industries, particularly automotive manufacturers. These clamps are vital for connecting vacuum hoses, air intake systems, and fuel lines. A reliable hose clamp ensures that these connections remain secure under varying pressure conditions, contributing to the overall safety and efficiency of vehicles.

In the construction sector, hose clamps play a critical role in plumbing and water management systems. Their ability to secure hoses ensures that water transport remains uninterrupted, preventing leaks that could lead to costly damages and safety hazards.

Conclusion

Hose clamp factories, particularly those focused on producing 9/16 clamps, are essential to the smooth operation of multiple industries. Through meticulous manufacturing processes and stringent quality control, these factories contribute significantly to the reliability and safety of various systems by providing high-quality hose clamps. As industries continue to evolve, the demand for reliable hose clamps will persist, underscoring the importance of these specialized manufacturers in the global supply chain.

-

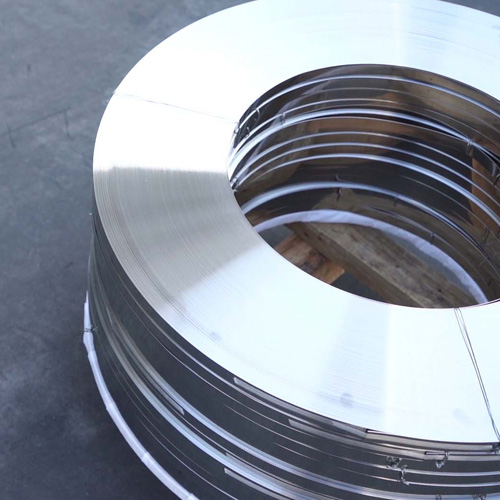

Premium 316L Stainless Steel Strip | Corrosion Resistant

NewsAug.27,2025

-

Durable Adjustable Stainless Steel Hose Clamp - Secure & Rust-Proof

NewsAug.26,2025

-

Premium Adjustable Stainless Steel Hose Clamps for Secure Sealing

NewsAug.25,2025

-

Premium Stainless Steel Hose Clamp - Durable & Rust-Proof

NewsAug.24,2025

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025