- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

mart. . 21, 2024 12:26 Back to list

no hub coupling-Are you tightening the Hose Clamp the Right way?

Are you tightening the Hose Clamp the Right way?

Tightening the hose clamp is not as easy job as tightening a regular fastener. This process from far seems to be very simple but involves a series of complex events which is highly overlooked by the industry & the end-users which often leads to underutilization of a clamps ability & unwelcomed leak issues. In this article, we will try to understand the correct method of tightening a hose clamp & important points to keep in mind while tightening one.

1. Installation Torque-

It is the recommended torque for the installation of the clamp by the standard or manufacturer. Installation torque is sometimes referred to as Application torque. Applying the exact amount of torque is necessary for producing an efficient hose joint. The important point to be noted is that the clamp performance depends on the actual clamping force (reported as either Band tension or Radial load) generated by the clamp & not on the Torque applied. Increasing the application torque beyond the specified limit may lead to permanent deformation of the clamp or hose & seizing/jamming of the clamp. Installation torque values given on the drawing may not be exceeded in any case. For clamp wise installation torque values to be set, refer our product catalogue for more details.2. Tightening Speed-

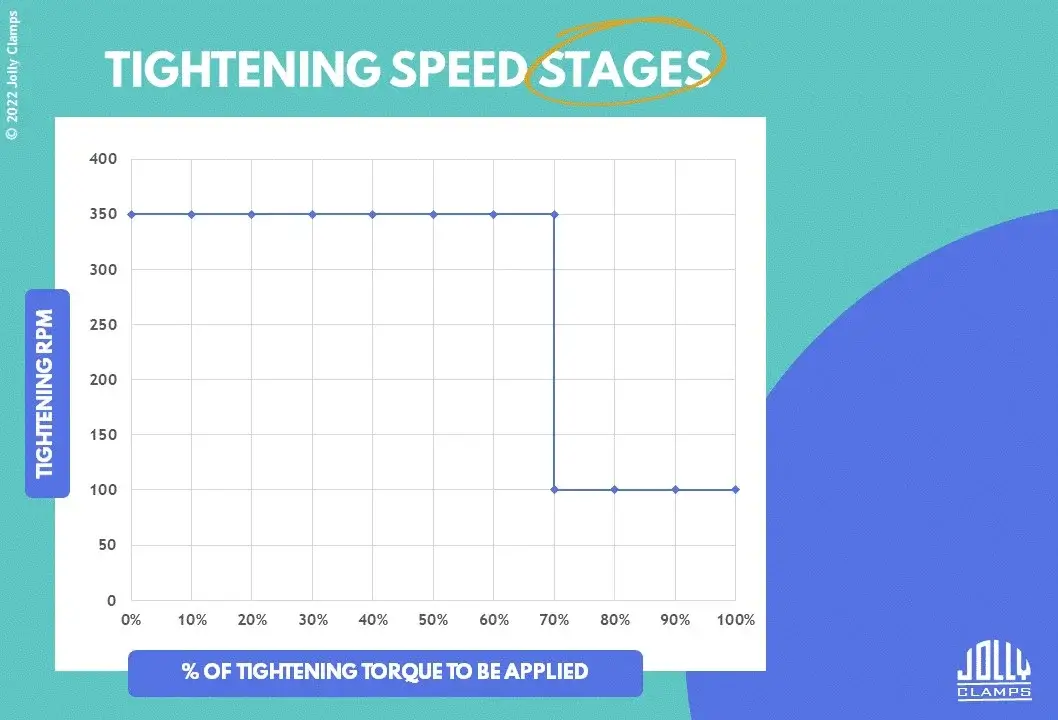

Figure 1- Tightening speed stages graph

Figure 1- Tightening speed stages graphIt is the speed that the tightening tool imparts on the screw for tightening the clamp. Increasing the tightening speed too much will increase your productivity but will cut down your joint quality. On the other hand, reducing the speed for improving the joint quality will bring down your productivity. Instead, a trade-off between the two the Dual-step tightening process should be adopted.

•Step 1: until 70 % of the recommended nominal torque (see individual drawing), speed: max. 350 rpm.

•Step 2: Rest 30% of the recommended nominal torque, speed: 120-100 rpm.

Figure 2- Clamp joint Productivity Vs Quality

Figure 2- Clamp joint Productivity Vs QualityIn case of tightening of Hose clamps, Constant Shut-Off type Nut Runner is recommended for uniform delivery of application torque. Hammer Type Nut runner should not be used as they have Pulsating nature of torque delivery.

3. Hose insertion on Pipe-

Insertion of the Hose onto the Pipe/Spigot is the first step in the clamp tightening journey. Although the hose can be directly pushed onto the pipe for ease in assembly when possible “PARAFLU” (A Monoethylene Glycol based coolant), 50% diluted with water should be used. The use of lubricants/soap solutions should not be entertained as using them may lead to slippage of the joint. Shop here for Glycol-based coolant. While hose insertion, care must be taken with respect to pipe bead & stopper for the hose.

4. Positioning of the clamp-

The clamp should be assembled perpendicular to the center of the joint. Sufficient space must be kept near the edge of the clamp band for the hose as shown in the figure.

Figure 3- The clamp fitted on the hose should be positioned as indicated above

Tech Tips to tight the clamp -

- It may be useful to retighten the connections 1-5 minutes after the initial clamp assembly (for example, for tightening check at the assembly line). No further retightening steps are recommended.

- Fully opening of the clamp and remounting of the band to the housing should be strongly avoided.

- Always use standard sockets manufactured by good quality manufacturers.

- Welded socket combinations are often seen on production lines, this can prove to be dangerous as high torque levels can cause a sudden crack in the welding. This puts the well-being of the operator at risk and can damage the assembled part. Such unfair practices should be prohibited on the shop floor.

- In cases with accessibility challenges where long unguided socket and extension on a power tool are used, they must be employed with Rotaction guides to prevent long socket wobbling. Wobbling is highly undesirable as during high torque & rpm it may distort the sheet metal housing & clamp assembly.

Share

Latest news

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025

-

Durable Hose Clamps with GPT-4 Turbo Tech | Secure Sealing

NewsJul.31,2025