- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 18, 2025 04:24 Back to list

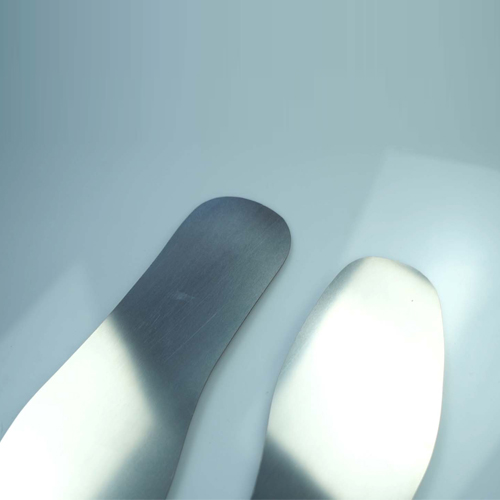

hose clamp band

Hose clamp bands, often overlooked yet essential tools in various industries, embody a blend of engineering mastery and practical necessity. In the realm of fluid systems management, hose clamp bands serve as the unsung heroes that maintain system integrity and ensure seamless operations.

Authoritativeness in the domain of hose clamps is established by understanding the standards and certifications that apply. Reliable hose clamp bands adhere to industry standards such as the SAE (Society of Automotive Engineers) J1508 and DIN3017, ensuring they meet stringent safety and performance criteria. Trusting a supplier that complies with these standards is crucial for professionals seeking reliability. Trustworthiness in selecting the right hose clamp band is further enhanced by considering the manufacturer's reputation and customer feedback. Brands known for rigorous testing protocols and excellent customer service are preferable, as they demonstrate a commitment to quality. In practice, this translates to a reduced risk of failure and a longer lifespan of the equipment into which they are integrated. For consumers and professionals alike, understanding the application-specific requirements for hose clamp bands is vital. This includes the diameter, material, band width, and type of clamp employed. For instance, screw clamps are ideal for applications requiring high torque, while wire clamps might be suitable for lighter, flexible tubing. In conclusion, hose clamp bands, though small in stature, wield significant influence over the safety and efficiency of numerous applications. Their design and material choices must be made with consideration to the operating conditions they will face. Drawing on a thorough understanding of both technical standards and real-world performance data can ensure that the optimal choice is made. Emphasizing durability, compliance with industry standards, and trustworthy sourcing establishes a paradigm in which hose clamps are not merely components but pivotal elements of your project's success. Recognizing their importance and selecting the right clamp can safeguard operations, enhance performance, and ensure long-term reliability across any application.

Authoritativeness in the domain of hose clamps is established by understanding the standards and certifications that apply. Reliable hose clamp bands adhere to industry standards such as the SAE (Society of Automotive Engineers) J1508 and DIN3017, ensuring they meet stringent safety and performance criteria. Trusting a supplier that complies with these standards is crucial for professionals seeking reliability. Trustworthiness in selecting the right hose clamp band is further enhanced by considering the manufacturer's reputation and customer feedback. Brands known for rigorous testing protocols and excellent customer service are preferable, as they demonstrate a commitment to quality. In practice, this translates to a reduced risk of failure and a longer lifespan of the equipment into which they are integrated. For consumers and professionals alike, understanding the application-specific requirements for hose clamp bands is vital. This includes the diameter, material, band width, and type of clamp employed. For instance, screw clamps are ideal for applications requiring high torque, while wire clamps might be suitable for lighter, flexible tubing. In conclusion, hose clamp bands, though small in stature, wield significant influence over the safety and efficiency of numerous applications. Their design and material choices must be made with consideration to the operating conditions they will face. Drawing on a thorough understanding of both technical standards and real-world performance data can ensure that the optimal choice is made. Emphasizing durability, compliance with industry standards, and trustworthy sourcing establishes a paradigm in which hose clamps are not merely components but pivotal elements of your project's success. Recognizing their importance and selecting the right clamp can safeguard operations, enhance performance, and ensure long-term reliability across any application.

Share

Next:

Latest news

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025