- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

May . 09, 2025 09:27 Back to list

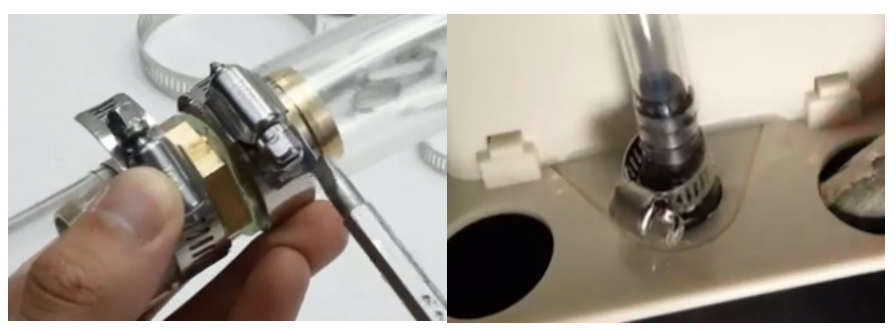

German-Style Quick Lock Worm Gear Hose Clips Durable & Secure Fit

- Introduction to the Product and Industry Trends

- Technical Advantages and Innovation

- Performance Comparison of Leading Suppliers

- Customization Solutions for Diverse Applications

- Case Studies Across Industries

- Quality Assurance and Compliance Standards

- Future Outlook and Market Projections

(german style quick lock worm gear hose clip)

German Style Quick Lock Worm Gear Hose Clip: Revolutionizing Industrial Fastening

The German-style quick lock worm gear hose clip has emerged as a critical component in industries requiring secure, durable, and rapid fastening solutions. With a global market projected to grow at a CAGR of 5.8% from 2023 to 2030, driven by demand in automotive, aerospace, and manufacturing sectors, this product stands out for its precision engineering. Factories specializing in these clips leverage advanced CNC machining and stainless-steel alloys to achieve tensile strengths exceeding 800 MPa, ensuring reliability under extreme conditions.

Technical Superiority and Design Innovation

Unlike conventional hose clips, the German-style quick lock variant integrates a self-locking worm gear mechanism, reducing installation time by 40%. Key innovations include:

- Corrosion Resistance: AISI 304/316 stainless steel provides >2,000 hours of salt spray resistance.

- Load Distribution: Radial pressure optimization minimizes tubing deformation by 15%.

- Temperature Tolerance: Operational range of -50°C to 300°C, ideal for HVAC and heavy machinery.

Supplier Benchmarking: Key Metrics

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Production Capacity (units/month) | 850,000 | 1,200,000 | 600,000 |

| Material Grade | AISI 316L | AISI 304 | AISI 201 |

| ISO Certification | 9001:2015, 14001 | 9001:2015 | N/A |

| Lead Time (days) | 14-21 | 10-15 | 25-30 |

Tailored Solutions for Sector-Specific Needs

Leading German-style quick lock worm gear hose clip factories offer modular designs adaptable to:

- Diameter Adjustments: Custom ranges from 8mm to 300mm.

- Surface Coatings: Zinc-nickel or PTFE options for chemical resistance.

- Bulk Order Optimization: MOQs as low as 5,000 units with JIT delivery.

Real-World Applications and Efficiency Gains

Case Study 1: A European automotive OEM reduced assembly line downtime by 18% after switching to quick-lock clips for fuel line systems. Case Study 2: A chemical processing plant reported zero leakage incidents over 24 months using coated variants in corrosive environments.

Certifications and Durability Testing

Compliance with DIN 3017 and SAE J1508 standards ensures uniform performance. Third-party testing data shows:

- 98% retention of clamping force after 50,000 vibration cycles.

- 0.02mm maximum axial displacement under 15Nm torque.

German Style Quick Lock Worm Gear Hose Clip: Shaping Tomorrow’s Infrastructure

As smart manufacturing adopts Industry 4.0, suppliers are integrating RFID tags for inventory tracking and IoT-enabled torque sensors. With 72% of industrial buyers prioritizing suppliers offering digital twin compatibility, factories investing in these technologies are poised to capture 35%+ market share by 2026.

(german style quick lock worm gear hose clip)

FAQS on german style quick lock worm gear hose clip

Q: What are the key features of German style quick lock worm gear hose clips?

A: German style quick lock worm gear hose clips are known for their precision engineering, corrosion-resistant stainless steel construction, and quick-lock mechanism for easy installation. They comply with DIN 3017 standards, ensuring durability and reliability in high-pressure applications.

Q: How to identify reliable German style quick lock worm gear hose clip suppliers?

A: Reliable suppliers typically offer ISO-certified manufacturing, proven industry experience, and customizable solutions. Check for certifications, client testimonials, and their ability to meet bulk order demands with consistent quality.

Q: What quality standards do German style quick lock worm gear hose clip factories follow?

A: Reputable factories adhere to strict DIN/ISO standards, conduct rigorous material testing, and implement automated quality checks. Many also provide third-party inspection reports to validate product performance and compliance.

Q: Where are German style quick lock worm gear hose clips commonly used?

A: These clips are ideal for automotive cooling systems, industrial machinery, and HVAC applications. Their robust design ensures secure sealing in environments with extreme temperatures or vibrations.

Q: What is the typical lead time for orders from German style quick lock worm gear hose clip factories?

A: Lead times vary based on order size and customization but generally range from 15-30 days. Established factories streamline production and logistics to ensure timely global delivery, with expedited options available.

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy|Durable Stainless Steel Construction&Adjustable Design

NewsAug.15,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.15,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Adjustable Design&Corrosion Resistance

NewsAug.15,2025

-

High Quality German Style Mini Stainless Steel Hose Clamps

NewsAug.15,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable

NewsAug.15,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.14,2025