- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ਦਸੰ. . 05, 2024 15:10 Back to list

Explore Top Manufacturers for 2% 3% and 4% Hose Clamps in the Industry

The Evolution and Importance of Hose Clamp Factories A Focus on 2%, 3%, and 4% Production Standards

Hose clamps are essential components used in various industries, including automotive, plumbing, and manufacturing. They serve a critical function in securing hoses to fittings, preventing leaks and ensuring the integrity of fluid systems. As industries evolve, so do the demands on hose clamp production. This article delves into the significance of hose clamp factories producing to the standards of 2%, 3%, and 4% efficiency, examining their impact on quality, cost, and reliability.

Understanding the Production Standards

In the industrial realm, production efficiency is often expressed in percentage terms, indicating the amount of output relative to input resources. For hose clamp factories, achieving 2%, 3%, and 4% production standards is crucial for several reasons

1. Quality Assurance A 2% production standard implies that 2% of the production process is dedicated to ensuring quality checks. This includes rigorous testing and inspection of materials, designs, and finished products. High-quality hose clamps are essential to prevent failures that could lead to costly repairs and unsafe conditions.

2. Cost Effectiveness When a factory operates at a 3% production standard, it indicates a balanced focus on efficiency, quality, and cost management. This standard helps factories minimize waste, optimize resource usage, and maintain competitive pricing in a market that demands both affordability and reliability.

3. Scalability and Flexibility A production standard of 4% reflects an advanced level of efficiency that allows factories to scale operations swiftly. Such flexibility is essential for meeting sudden spikes in demand, particularly in industries affected by seasonal trends or unexpected events.

The Role of Technology in Production Efficiency

Advancements in technology have fundamentally transformed the hose clamp manufacturing process. Automation and smart manufacturing systems enable factories to streamline production, reduce human error, and enhance precision. With machinery capable of operating at high speeds while maintaining strict quality control, factories producing hose clamps can meet the demanding 2%, 3%, and 4% standards effectively.

2 3 4 hose clamp factories

Moreover, the integration of data analytics allows manufacturers to monitor production processes in real-time, identifying bottlenecks and optimizing workflows. This technological evolution not only boosts efficiency but also enhances the capacity for innovation in product design and materials.

Environmental Considerations

As industries become more eco-conscious, hose clamp factories are also adjusting their production processes to align with sustainability goals. Factories producing to 2%, 3%, and 4% standards often implement practices that minimize environmental impact. This includes utilizing recyclable materials, reducing waste during production, and adopting energy-efficient technologies.

Sustainability is not only beneficial for the environment but also enhances a factory's marketability. Consumers today are more likely to choose products from companies that demonstrate a commitment to eco-friendly practices.

The Competitive Landscape

The global market for hose clamps is competitive, with numerous manufacturers vying for market share. Factories that can effectively operate at high production standards while maintaining consistent quality will likely thrive. They can cater to diverse sectors including automotive, aerospace, and industrial applications, which all require reliable hose clamps that can withstand varying pressures and temperatures.

Furthermore, a commitment to quality and efficiency bolsters customer trust. Clients are more inclined to establish long-term partnerships with factories that consistently deliver high-quality hose clamps, driven by solid production standards.

Conclusion

In conclusion, hose clamp factories achieving 2%, 3%, and 4% production efficiencies play a vital role in the manufacturing landscape. By prioritizing quality, cost-effectiveness, and adaptability, these factories not only meet the rigorous demands of modern industries but also contribute positively to environmental sustainability. As technology continues to advance, the focus on efficient production will only enhance the importance of hose clamps in various applications, underscoring their role as critical components in countless systems and industries worldwide.

-

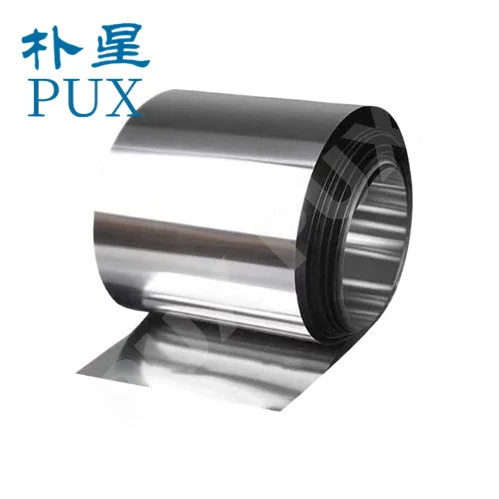

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025