- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

May . 09, 2025 13:59 Lura għal-lista

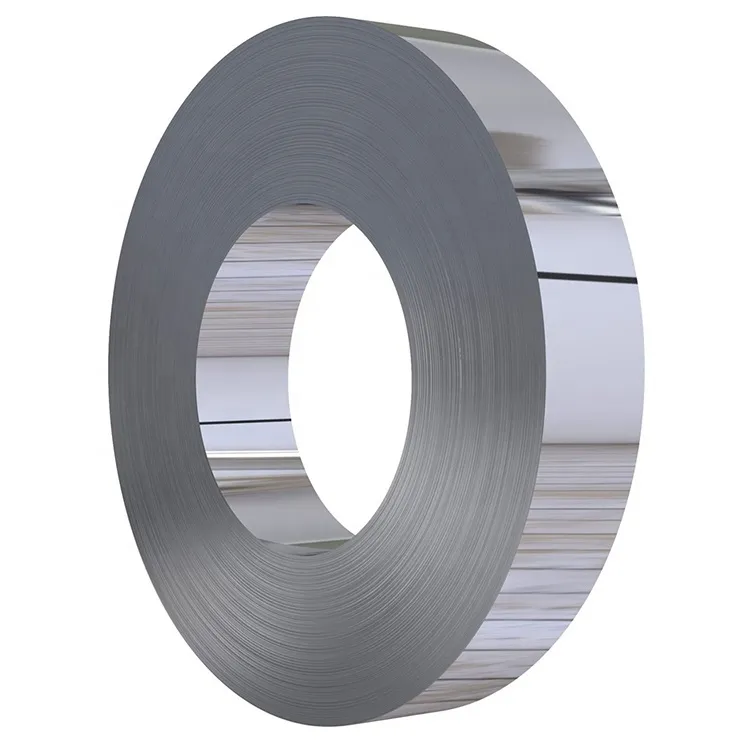

Strong And Reliable Steel Strip Choices

The 1mm steel strip has become a trusted material across multiple industries due to its flexibility, strength, and adaptability in forming processes. Whether it’s being used in light structural reinforcements, tooling, or automotive interior bracketing, this thin steel strip provides a consistent solution where tighter tolerances and high wear resistance are crucial. Manufacturers often prefer it for components that require fine adjustments or compact fitting. The ease of shaping and cutting 1mm steel strip without sacrificing durability is a major reason for its broad use in small machinery and precision engineering. For businesses focusing on production that requires lightweight yet resilient materials, this type of strip ensures productivity and consistent output, especially when batch cutting and edge processing are involved.

Durable Support From 2 Inch Wide Steel Strip In Heavy Use

In applications demanding wider surface contact and structural support, the 2 inch wide steel strip provides the ideal base material. Its wider format gives better load distribution, making it an excellent option for bracket systems, mounting supports, and structural backings. Industries such as construction, warehouse racking, and packaging systems regularly turn to this strip for consistent dimensional strength. The uniform width ensures seamless welding, fastening, or lamination in heavy-use environments. Additionally, the strength-to-width ratio allows for increased tension resistance, making it suitable for metal housing units and equipment protection edges. When precise flatness and width stability are needed for industrial templates or press-formed parts, the 2 inch wide steel strip answers reliably.

Common Uses Of 201 Stainless Steel Strip In Modern Production

The 201 stainless steel strip continues to gain attention due to its affordability and strength in environments where corrosion is a consideration but not the primary concern. Widely used in cookware, furniture brackets, appliance components, and automotive trims, 201 stainless offers a balance between formability and tensile strength. It retains a smooth finish, which helps during polishing and aesthetic surface treatments. Its nickel-manganese alloy composition reduces costs while still offering the key properties of stainless steel. This makes it popular among OEM suppliers and component makers seeking economical solutions without sacrificing quality. As demand grows for lightweight, aesthetically polished parts, the versatility of 201 stainless becomes an essential resource for many mass production needs.

Choosing The Right 201 Stainless Steel Strip Supplier For Bulk Needs

For factories, wholesalers, and fabrication shops, partnering with a reliable 201 stainless steel strip supplier is key to maintaining steady production and minimizing material-related delays. Quality suppliers not only deliver in bulk but also provide material certification, surface treatment options, and thickness variation suited to different fabrication lines. Choosing a supplier who specializes in 201 grade ensures consistency in mechanical properties and process compatibility, which is especially critical when rolling, cutting, or stamping in high-volume workflows. With global sourcing becoming more streamlined, companies now require more than just competitive pricing—they demand traceability, fast lead times, and customization. When the supplier has expertise in this particular grade, it simplifies planning for product runs, packaging configurations, and even inventory planning.

Cost And Weight Balance With 1mm Steel Strip For Thin Forming

While thicker materials often dominate in heavy industry, the cost and weight advantages of 1mm steel strip bring unique opportunities to light manufacturing and component fabrication. For example, small enclosures, clips, and low-stress joining brackets benefit from the lighter mass and manageable strength. The minimal material weight allows for easier transport and handling, reducing overhead across the supply chain. In projects where energy consumption in cutting and shaping needs to be kept low, this thin strip reduces tool wear and cycle time. By choosing the right coating or galvanization, it can also achieve respectable resistance to environmental conditions. Cost-effective, lightweight, and adaptable, this format is a practical choice for operations where throughput and versatility are prioritized.

201 Stainless Steel Strip Supplier FAQs

What should I look for in a good 201 stainless steel strip supplier?

You should seek consistent quality, full material traceability, customizable surface finishes, and responsive delivery timelines.

Can 201 stainless steel strip be used in high-moisture environments?

While it has moderate corrosion resistance, for very wet or marine conditions, a higher-grade stainless steel may be preferred.

What are the most common thicknesses available from 201 stainless steel strip suppliers?

Common thicknesses range from 0.3mm to 3.0mm depending on the supplier and application type.

Is it cost-effective to order 201 stainless steel strip in bulk?

Yes, ordering in bulk significantly reduces the cost per unit and ensures consistent material availability.

Can suppliers offer slitting and edge treatment for 201 stainless steel strip?

Many suppliers provide value-added services like precision slitting, deburring, and even protective film application.

-

The Impact of Automation on Crimp Hose Clamp Kit Production

AħbarijietAug.08,2025

-

Quality Control Measures in Precision Stainless Steel Strip Production

AħbarijietAug.08,2025

-

Market Analysis of China's Mini Hose Clamp Industry

AħbarijietAug.08,2025

-

How Stainless Steel Strip Enhances the Durability of Hose Clamps

AħbarijietAug.08,2025

-

Customization Options for American Type Radiator Hose Clamp

AħbarijietAug.08,2025

-

Compatibility and Installation Best Practices for Stainless Steel Hose Clips

AħbarijietAug.08,2025