- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

डिसेंबर . 03, 2024 19:46 Back to list

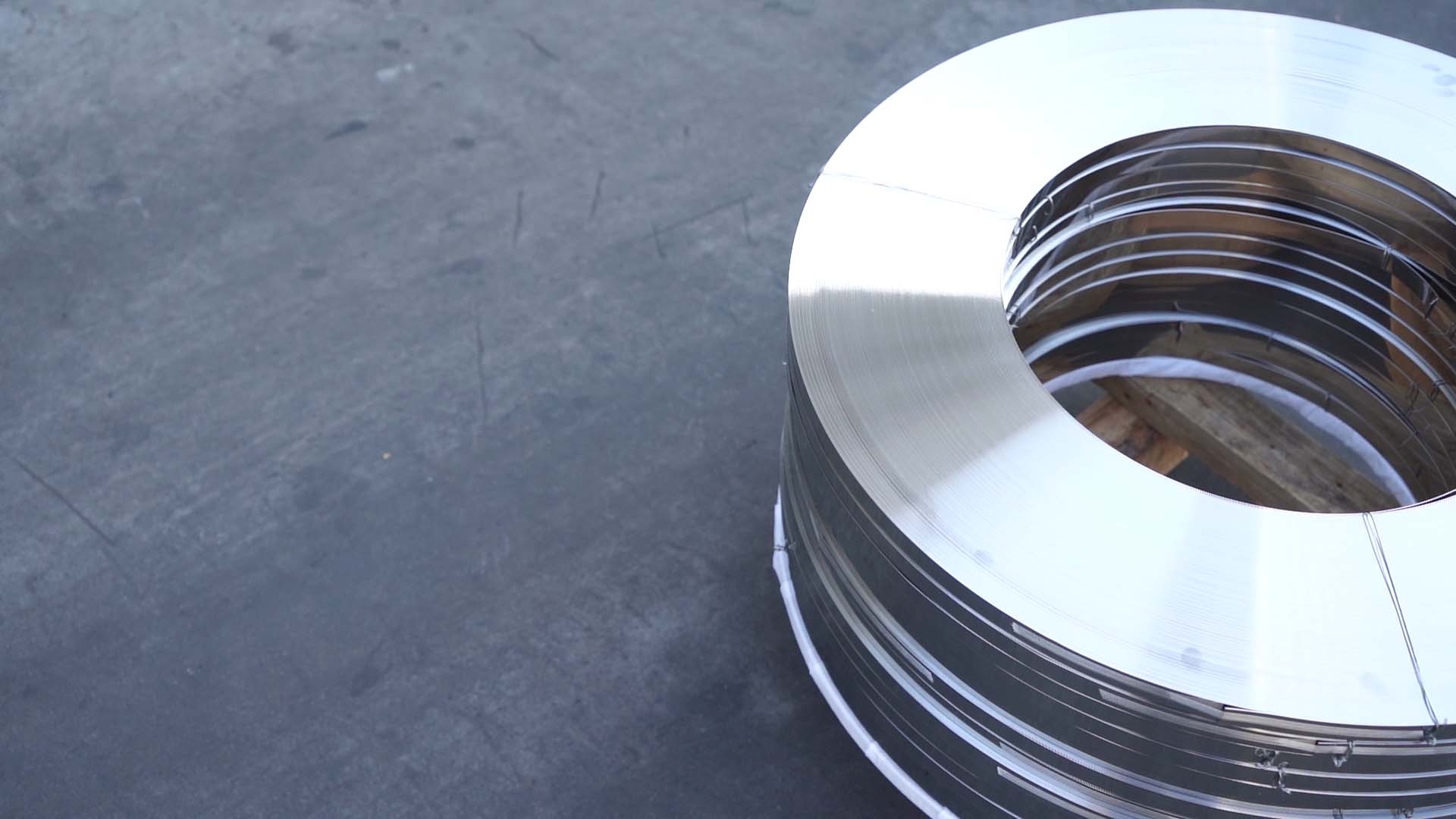

Manufacturers of Durable Black Steel Bands for Various Applications

The Evolution and Significance of Black Steel Band Factories

In the dynamic landscape of manufacturing, black steel band factories have carved a distinct niche as vital contributors to various industries. This article delves into the evolution, production processes, and significance of these factories, highlighting their role in modern manufacturing.

Understanding Black Steel Bands

Black steel bands, often referred to as black iron bands, are typically made from low-carbon steel, which is manufactured through a process that ensures durability and strength. The term black refers to the surface finish of the steel, which has a dark color due to the rolling process and the presence of iron oxide. These bands are characterized by their high tensile strength, flexibility, and resistance to corrosion, making them suitable for a wide range of applications.

Historical Context

The origin of steel band manufacturing can be traced back to the early days of industrialization, when companies sought to create materials that could withstand the rigors of various applications. Over the years, advancements in metallurgy and production technology have revolutionized the way black steel bands are produced. Initially, manufacturing methods were labor-intensive, relying on manual processes that limited production capacity and efficiency.

With the advent of modern machinery and automation in the late 20th century, black steel band factories transformed dramatically. High-speed rolling mills and advanced welding techniques have enabled manufacturers to produce black steel bands in varying widths and thicknesses, catering to the diverse needs of industries such as construction, automotive, and manufacturing.

Production Process

The production of black steel bands involves several key steps.

1. Raw Material Selection The process begins with the selection of high-quality low-carbon steel. This raw material is essential for ensuring the durability and flexibility of the finished product.

2. Hot Rolling The selected steel is then heated and passed through a series of rollers to achieve the desired thickness. This hot rolling process is crucial, as it enhances the mechanical properties of the steel.

black steel band factories

3. Cooling After rolling, the steel bands are cooled to room temperature. This step is vital to stabilize the material and achieve the required strength characteristics.

4. Shearing and Cutting Once cooled, the bands are cut to specific lengths based on customer specifications. Precision in this step is imperative to ensure that the final product meets industry standards.

5. Finishing Finally, the bands might undergo further processes such as surface treatment to enhance corrosion resistance and improve appearance. This can include processes like galvanization or powder coating, depending on customer requirements.

Applications and Industries

Black steel bands are utilized across a multitude of industries. In the construction sector, they are often used for reinforcing concrete structures and securing various types of equipment. The automotive industry employs black steel bands for manufacturing components like exhaust systems and chassis parts. Additionally, they are critical in the manufacturing of packaging materials, such as strapping for pallets and securing loads during transport.

The versatility of black steel bands makes them indispensable in numerous sectors. Their strength, durability, and adaptability to various environmental conditions position them as preferred materials in an increasingly competitive marketplace.

Future Trends

As we look toward the future, black steel band factories are poised to innovate further. The push for sustainability and environmentally friendly practices is influencing production techniques. Many factories are now exploring the use of recycled materials and energy-efficient manufacturing processes in response to growing environmental awareness.

Moreover, advancements in digital technologies, such as automation and artificial intelligence, are set to redefine efficiency in production. By incorporating these technologies, factories can optimize production lines, reduce waste, and improve product quality, thus meeting the ever-evolving demands of the market.

Conclusion

In conclusion, black steel band factories play a crucial role in the manufacturing landscape, supporting a diverse array of industries with their innovative and durable products. As these factories continue to evolve in response to technological advancements and sustainability concerns, they will undoubtedly remain a cornerstone of modern manufacturing, driving growth and innovation in the global economy. The future of black steel bands looks promising, filled with opportunities for enhanced efficiency, quality, and sustainability.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025

-

Black Rubber Hose Clamps - Insulated & Protected

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion-Resistant Adjustable Design

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.11,2025