- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ഡിസം . 09, 2024 16:35 Back to list

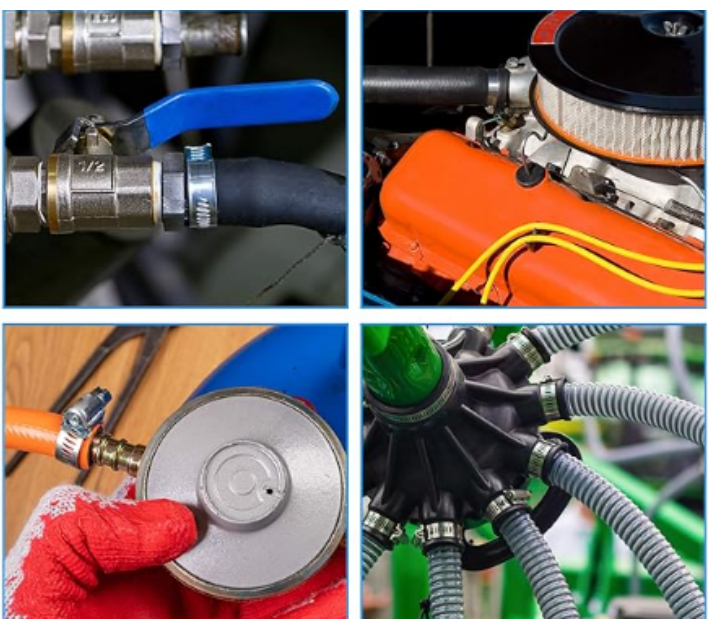

High-Quality Automotive Hose Clamps for Heavy-Duty Applications and Custom Solutions

Heavy Duty Automotive Hose Clamps Manufacturer Ensuring Quality and Durability

In the automotive industry, the reliability of components is paramount, and one of the critical elements that often gets overlooked is the hose clamp. A heavy-duty automotive hose clamp is designed to secure hoses tightly to fittings, ensuring that fluids and gases are transported safely and efficiently. Selecting the right manufacturer is crucial for achieving the quality and durability needed in high-stress environments. This article delves into the significance of heavy-duty automotive hose clamps, their key features, and what to look for in a manufacturer.

The Importance of Heavy-Duty Hose Clamps

Automotive applications involve exposure to varying temperatures, pressures, and corrosive substances. Heavy-duty hose clamps are specifically engineered to withstand these harsh conditions. They play an essential role in preventing leaks, ensuring system integrity, and improving the overall performance of automotive systems. For example, in cooling systems, a secure hose connection can prevent coolant loss, which might otherwise lead to overheating and engine failure. Similarly, in fuel systems, improperly secured hoses can result in dangerous leaks, posing safety hazards to both vehicle occupants and the environment.

Key Features of Heavy-Duty Hose Clamps

When assessing heavy-duty automotive hose clamps, several features should be taken into account

1. Material Quality Heavy-duty clamps are typically made from high-grade stainless steel, carbon steel, or other durable materials that provide resistance to corrosion and mechanical stress. The material choice directly impacts the clamp's longevity and performance.

2. Design The design of the clamp should facilitate a secure grip without damaging the hose. Many manufacturers offer clamps with rolled edges or specially designed teeth to prevent cutting into the hose material.

3. Adjustability A reliable hose clamp should be adjustable to accommodate different hose diameters. This flexibility is essential for manufacturers and service providers who deal with various vehicle makes and models.

4. Ease of Installation Heavy-duty clamps should allow for easy installation and removal, which can be particularly beneficial in repair scenarios where time efficiency is crucial.

heavy duty automotive hose clamps manufacturer

5. Performance Under Pressure It’s imperative that the clamps maintain their integrity under high pressure and temperature fluctuations, characteristic of automotive environments.

Finding the Right Manufacturer

When searching for a heavy-duty automotive hose clamp manufacturer, there are several factors to consider

1. Reputation Look for manufacturers with a well-established reputation in the industry. Reading reviews and seeking recommendations can help you assess their credibility.

2. Certifications and Standards Quality certifications such as ISO 9001 indicate that the manufacturer adheres to international standards of quality management. This is a good indicator of their commitment to producing reliable products.

3. R&D Capabilities A manufacturer that invests in research and development is likely to offer innovative solutions and products that meet evolving industry needs.

4. Customer Service Strong customer service is a hallmark of a reliable manufacturer. A company that supports its clients through the purchasing process and offers after-sales support demonstrates a commitment to customer satisfaction.

5. Product Range A manufacturer offering a wide range of hose clamps and related products can be advantageous for businesses requiring different types of clamps for various applications.

Conclusion

In conclusion, the role of heavy-duty automotive hose clamps in vehicle performance and safety cannot be overstated. Collaborating with a reputable manufacturer ensures that you receive high-quality, durable products that perform well under challenging conditions. By prioritizing material quality, design features, and manufacturer reliability, businesses in the automotive sector can significantly enhance their operational efficiency and safety standards.

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025