- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Фев . 14, 2025 14:40 Back to list

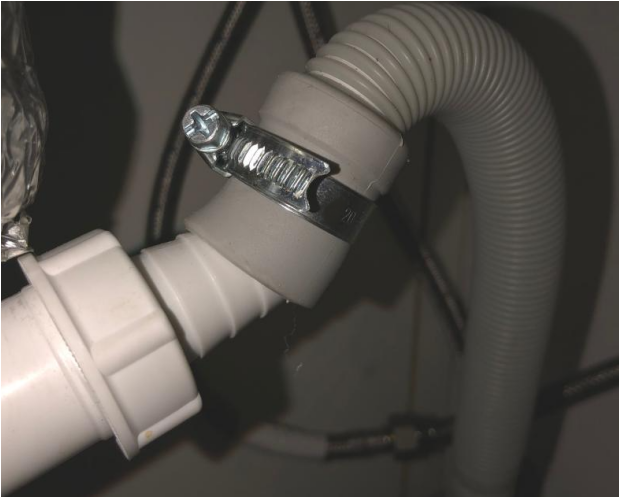

stainless steel hose clip

Understanding the nuances of FI hose clamps is essential for anyone involved in automotive repair, heavy machinery maintenance, or any industry where fluid integrity is crucial. These clamps are tiny yet powerful components that safeguard the effectiveness and performance of complex systems by ensuring hoses remain securely fastened, eliminating leaks that could yield disastrous results.

The process of installation and maintenance of FI hose clamps also speaks volumes for experience and trustworthiness. Ensuring a correct and firm installation reduces the risk of leakage and extends the life of both the clamp and the hose. It's crucial to employ the right tools and follow the manufacturer’s specifications closely. Periodic inspection and replacement are essential practices. Over time, even the most robust clamps may succumb to environmental wear. Regular checks can preemptively address small issues before they evolve into significant system failures. Investing in premium-quality FI hose clamps can save time and money in the long run. By ensuring a reliable and long-lasting seal, these clamps reduce maintenance intervals and system downtime, enhancing overall productivity and safety. Opting for clamps from reputable manufacturers guarantees adherence to industry standards, which is paramount for maintaining operation warranty and safety compliance. This proficiency extends beyond choosing and maintaining clamps. Understanding the particular demands of your systems and the environments they operate in is an authoritative step. Factors such as the fluid type, system pressure levels, and environmental impact should guide the selection process. For example, in applications carrying corrosive chemicals, the material choice for the clamp becomes critical, demanding non-corrosive properties without compromising on the gripping strength. While the functionality and practicality of FI hose clamps are apparent, establishing trustworthiness involves transparency and education. Offering detailed insights about product specifications, industry compatibility, and comprehensive usage guides fosters a well-informed decision-making process. Ensuring customers have access to this data builds confidence in the products they are investing in, reinforcing their trust and guaranteeing their systems run seamlessly with minimal risk of fluid system failures. Thus, the journey to mastering FI hose clamps combines a deep understanding of their materials, design, and application processes with a reliable and authoritative approach. This knowledge empowers industries to maintain durable and efficient fluid systems, safeguarding their operations while enhancing performance and reliability across diverse applications.

The process of installation and maintenance of FI hose clamps also speaks volumes for experience and trustworthiness. Ensuring a correct and firm installation reduces the risk of leakage and extends the life of both the clamp and the hose. It's crucial to employ the right tools and follow the manufacturer’s specifications closely. Periodic inspection and replacement are essential practices. Over time, even the most robust clamps may succumb to environmental wear. Regular checks can preemptively address small issues before they evolve into significant system failures. Investing in premium-quality FI hose clamps can save time and money in the long run. By ensuring a reliable and long-lasting seal, these clamps reduce maintenance intervals and system downtime, enhancing overall productivity and safety. Opting for clamps from reputable manufacturers guarantees adherence to industry standards, which is paramount for maintaining operation warranty and safety compliance. This proficiency extends beyond choosing and maintaining clamps. Understanding the particular demands of your systems and the environments they operate in is an authoritative step. Factors such as the fluid type, system pressure levels, and environmental impact should guide the selection process. For example, in applications carrying corrosive chemicals, the material choice for the clamp becomes critical, demanding non-corrosive properties without compromising on the gripping strength. While the functionality and practicality of FI hose clamps are apparent, establishing trustworthiness involves transparency and education. Offering detailed insights about product specifications, industry compatibility, and comprehensive usage guides fosters a well-informed decision-making process. Ensuring customers have access to this data builds confidence in the products they are investing in, reinforcing their trust and guaranteeing their systems run seamlessly with minimal risk of fluid system failures. Thus, the journey to mastering FI hose clamps combines a deep understanding of their materials, design, and application processes with a reliable and authoritative approach. This knowledge empowers industries to maintain durable and efficient fluid systems, safeguarding their operations while enhancing performance and reliability across diverse applications.

Share

Next:

Latest news

-

High-Quality Steel Plate Midsole - Trusted Factory & Suppliers for Safety Footwear

NewsJul.06,2025

-

High-Quality Stainless Steel Slit Coil Supplier & Factory – Precision Slitting, OEM Service

NewsJul.06,2025

-

High-Quality Hose Clamps Mini Clamp – Reliable Factory & Leading Suppliers

NewsJul.05,2025

-

High-Quality Steel Plate Midsole Leading Steel Plate Midsole Factories & Suppliers

NewsJul.05,2025

-

Adjustable Pipe Tube Clip – High-Quality, Durable & Versatile Clamps for Industrial Use

NewsJul.05,2025

-

German Style Hose Clamp Manufacturer Quick Lock Worm Gear Hose Clamp Supplier

NewsJul.04,2025