- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 23, 2024 11:31 Back to list

Factory for High-Quality Hot Dipped Galvanized Steel Strips Production and Supply

Understanding Hot Dipped Galvanized Steel Strip Factories

The demand for durable, corrosion-resistant materials in various industries has led to the widespread adoption of hot dipped galvanized steel strips. These strips are essentially steel sheets coated with a protective layer of zinc through a hot dipping process, ensuring they can withstand harsh environmental conditions. A hot dipped galvanized steel strip factory specializes in the production of these strips, which serve a multitude of applications ranging from construction and automotive to manufacturing and electrical industries.

The Hot Dipping Process

The hot dipping process is fundamental to the production of galvanized steel. It involves cleaning the steel surface to remove any oxides, oils, or dirt. After cleaning, the steel is dipped into a molten zinc bath at temperatures around 450 degrees Celsius. This process not only provides a robust coating of zinc but also allows for metallurgical bonding between the zinc and the iron in the steel, resulting in a superior corrosion-resistant product. The thickness of the zinc coating can be controlled based on the intended application, ensuring that the galvanized steel strip meets specific industry standards.

Importance of Quality Control

In a hot dipped galvanized steel strip factory, quality control is paramount. The entire production process is monitored to maintain high standards of quality. This involves regular inspection of raw materials, in-process checks, and final product assessments. Various tests, such as adhesion tests, thickness measurements, and corrosion resistance assessments, ensure that the steel strips will perform effectively in their intended applications. Adherence to international standards, such as ISO and ASTM, is critical in the manufacturing process, as it enhances the credibility and reliability of the product.

Applications of Galvanized Steel Strips

Galvanized steel strips produced in these factories find applications across various sectors. In construction, they are utilized for roofing sheets, sidings, and framing due to their strength and ability to resist rust and degradation over time. The automotive industry also leverages galvanized steel strips for components such as chassis and body panels, enhancing vehicle longevity and reducing maintenance costs. Electrical manufacturers use these strips for creating conduits and brackets, providing protection against environmental factors.

hot dipped galvanized steel strip factory

Environmental Considerations

One of the significant benefits of galvanized steel is its sustainability. The hot dipping process is designed to minimize waste and energy consumption. Zinc, which is abundant in the Earth's crust, is a sustainable resource. Moreover, galvanized steel can be recycled at the end of its life cycle, making it an environmentally friendly choice. Factories are increasingly implementing green technologies in their operations, such as water recycling systems and energy-efficient machinery, to further reduce their environmental impact.

The Future of Hot Dipped Galvanized Steel Strip Factories

As technology advances, hot dipped galvanized steel strip factories are embracing innovation to improve efficiency and product quality. The use of automation in production lines is becoming more prevalent, leading to reduced labor costs and increased precision in manufacturing. Furthermore, research into alternative zinc coating methods, such as zinc-aluminum alloys, is providing new avenues for enhancing the corrosion resistance of steel strips.

The global push towards sustainability is also influencing the future of galvanized steel production. Factories are adapting to stricter environmental regulations by developing practices that minimize emissions and waste. The integration of renewable energy sources into the production process is becoming a goal for many manufacturers, supporting the trend towards green manufacturing practices.

Conclusion

Hot dipped galvanized steel strip factories play a crucial role in producing materials that are essential for modern infrastructure and numerous industrial applications. With their commitment to quality control, adherence to environmental standards, and continuous innovation, these factories are well-positioned to meet the evolving demands of the global market. As industries continue to search for durable, cost-effective solutions, the relevance of hot dipped galvanized steel strips will undoubtedly endure, marking a significant presence in the future of manufacturing.

-

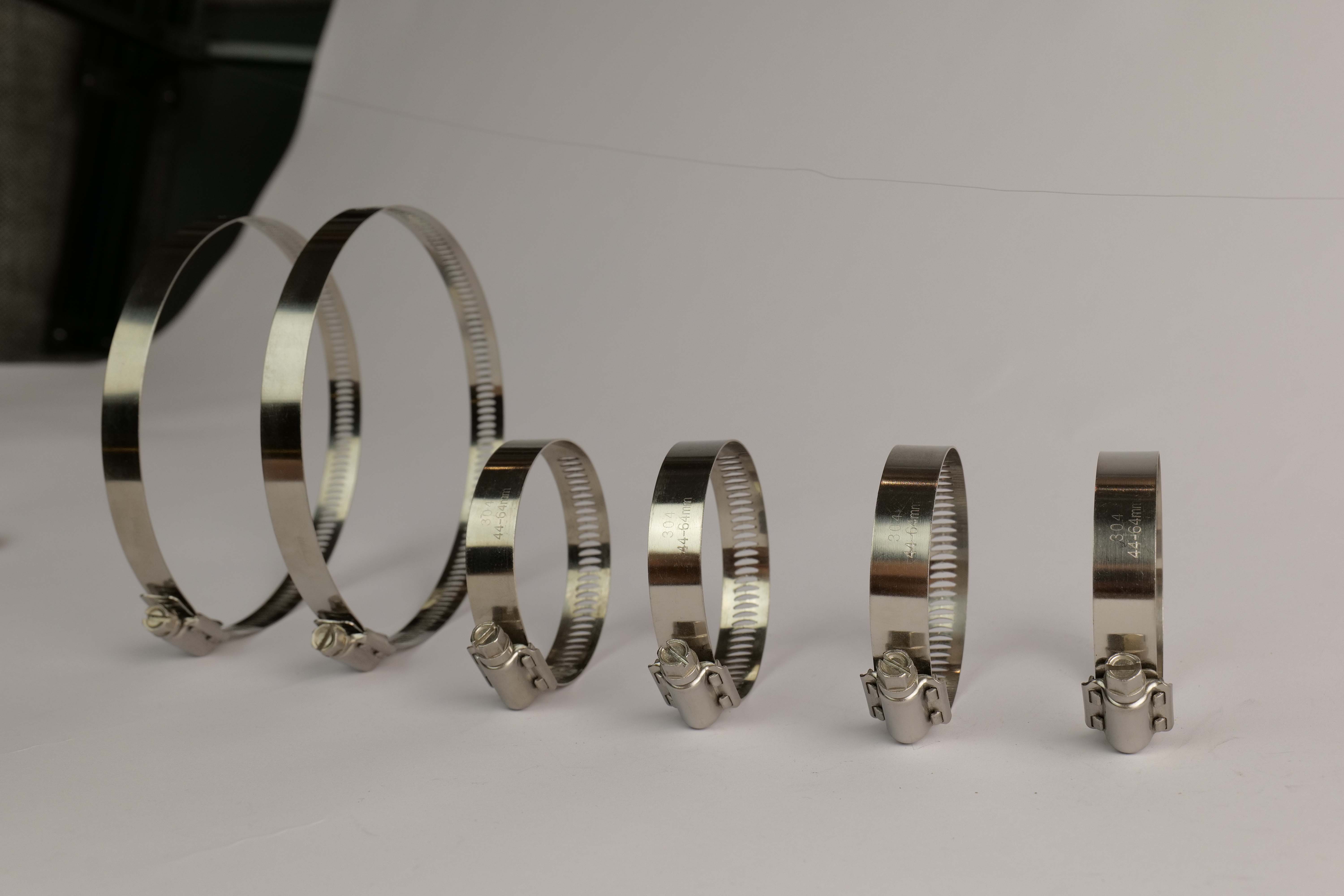

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.13,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | Corrosion Resistance, High Torque

NewsAug.13,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.13,2025

-

High Quality Hose Clamps & Mini Clips - German Stainless Steel

NewsAug.13,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.13,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.12,2025