- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Jan . 26, 2025 05:31 Back to list

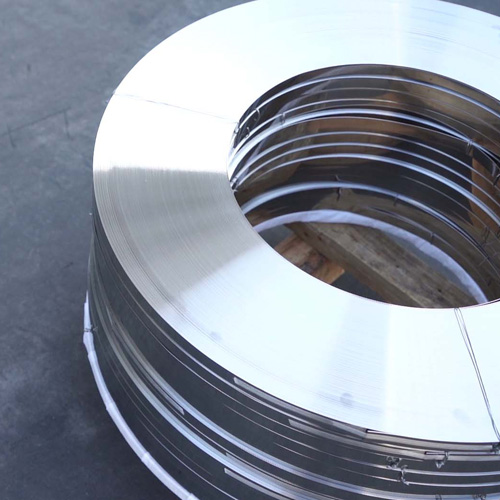

stainless hose clamp

The 9/16 hose clamp stands as a crucial component in various industries, praised for its versatility and reliability in securing hoses and tubing across multiple applications. Hose clamps may seem like a small detail in the grand scheme of system engineering, but their role is invaluable. Much like the unsung heroes of the mechanical world, hose clamps ensure efficiency, safety, and longevity.

When discussing authoritativeness in the realm of hose clamps, it is essential to reference standards and testing procedures that establish a product’s credibility. The 9/16 hose clamp often meets stringent industry standards, such as the Society of Automotive Engineers (SAE) requirements for automotive components. Additionally, these clamps undergo rigorous testing processes including pressure testing, corrosion resistance, and stress testing under adverse environmental conditions to ensure reliability across applications. Trustworthiness of a 9/16 hose clamp is established through consistent performance over time. Users often evaluate clamps based on their material composition, with stainless steel and other corrosion-resistant alloys offering the best longevity. Consumer reviews are an excellent resource for assessing trustworthiness, as many industry professionals share insights and feedback based on extensive product usage in various scenarios. Moreover, ensuring that the clamp is sourced from a reputable manufacturer can bolster trust. Established brands typically adhere to high manufacturing standards, facilitating peace of mind when these clamps are installed in critical systems. It is advised to verify manufacturer certifications and seek products that come with a warranty or guarantee of performance. In conclusion, the 9/16 hose clamp may be a small component, but its effectiveness in providing a secure, leak-proof connection is paramount to many mechanical and industrial applications. Personal experience, coupled with expert handling techniques, confirms its utility, while industry standards and lasting performance underscore its authoritativeness and trustworthiness. The key to maximizing the benefits of the 9/16 hose clamp lies in understanding its applications, installation, and maintenance. Properly utilized, this humble yet essential tool can contribute significantly to the safety, efficiency, and reliability of technical systems worldwide.

When discussing authoritativeness in the realm of hose clamps, it is essential to reference standards and testing procedures that establish a product’s credibility. The 9/16 hose clamp often meets stringent industry standards, such as the Society of Automotive Engineers (SAE) requirements for automotive components. Additionally, these clamps undergo rigorous testing processes including pressure testing, corrosion resistance, and stress testing under adverse environmental conditions to ensure reliability across applications. Trustworthiness of a 9/16 hose clamp is established through consistent performance over time. Users often evaluate clamps based on their material composition, with stainless steel and other corrosion-resistant alloys offering the best longevity. Consumer reviews are an excellent resource for assessing trustworthiness, as many industry professionals share insights and feedback based on extensive product usage in various scenarios. Moreover, ensuring that the clamp is sourced from a reputable manufacturer can bolster trust. Established brands typically adhere to high manufacturing standards, facilitating peace of mind when these clamps are installed in critical systems. It is advised to verify manufacturer certifications and seek products that come with a warranty or guarantee of performance. In conclusion, the 9/16 hose clamp may be a small component, but its effectiveness in providing a secure, leak-proof connection is paramount to many mechanical and industrial applications. Personal experience, coupled with expert handling techniques, confirms its utility, while industry standards and lasting performance underscore its authoritativeness and trustworthiness. The key to maximizing the benefits of the 9/16 hose clamp lies in understanding its applications, installation, and maintenance. Properly utilized, this humble yet essential tool can contribute significantly to the safety, efficiency, and reliability of technical systems worldwide.

Share

Next:

Latest news

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025