- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Rgs . 05, 2024 13:00 Back to list

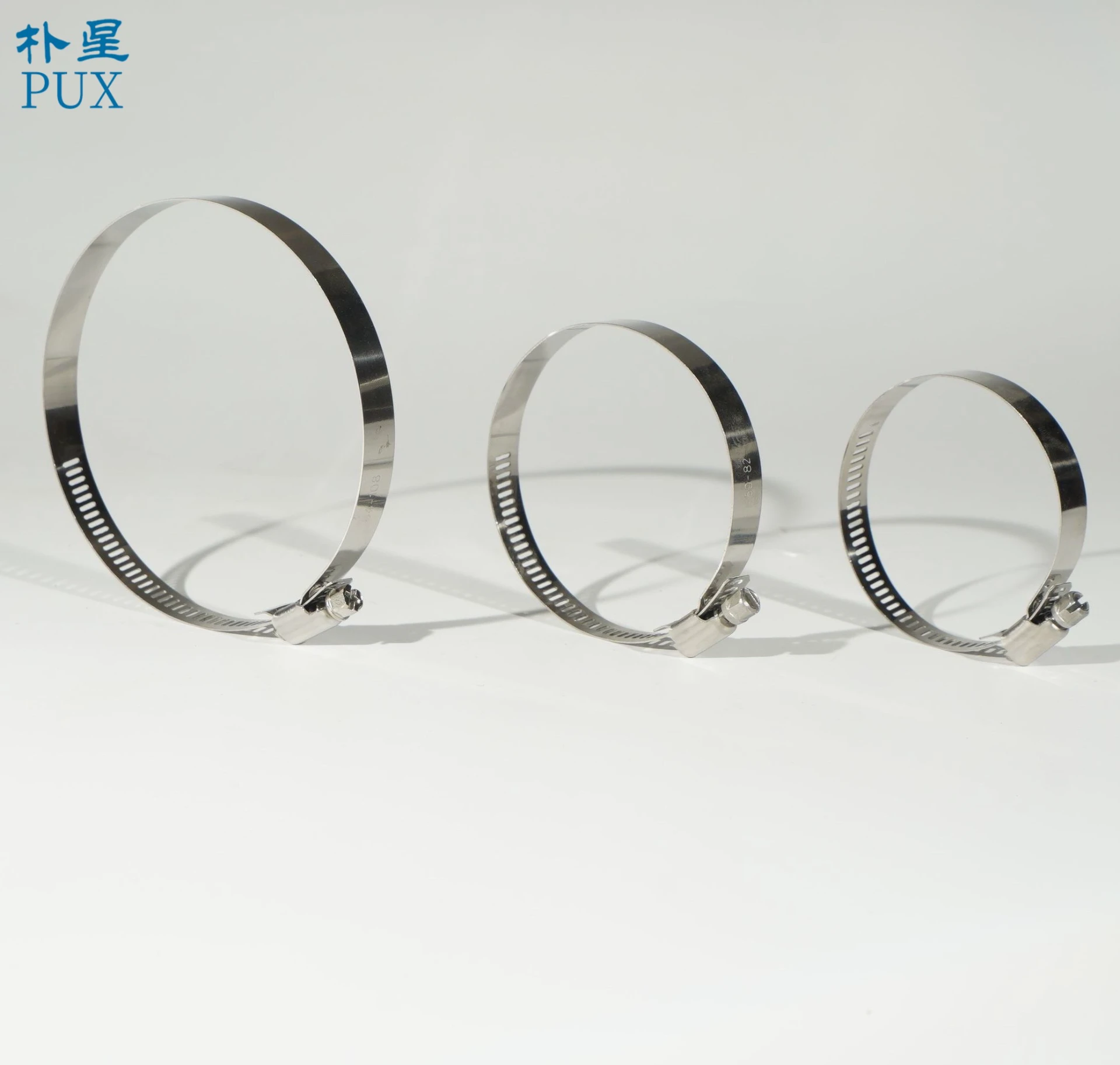

35mm hose clamp manufacturer

The Importance of Quality in 35mm Hose Clamp Manufacturing

In the world of industrial hardware, hose clamps play a crucial role in various applications, from automotive to plumbing systems. Among the various sizes available, the 35mm hose clamp stands out due to its versatility and widespread use. As demand for reliable and durable hose clamps increases, manufacturers need to prioritize quality, efficiency, and innovation in their production processes to meet customer needs.

What is a 35mm Hose Clamp?

A 35mm hose clamp is a fastening device that secures hoses to fittings such as tubes or pipes. It comprises a band that wraps around the hose and a screw mechanism that tightens the band, ensuring a firm grip. The dimensions of the clamp are ideal for various applications, making it a preferred choice for many industries, including automotive, construction, and agriculture.

Manufacturing Process

The manufacturing of 35mm hose clamps involves several key steps, each of which requires precision and attention to detail. The process typically begins with the selection of raw materials, which must be durable enough to withstand high pressures and resist corrosion. Common materials include stainless steel, galvanized steel, and plastic, depending on the intended application.

After materials are selected, they undergo forming processes using cutting, bending, and shaping techniques to create the band and mechanism. Advanced machinery, such as CNC machines and automatic bending tools, are often employed to ensure consistency and precision. Quality control checks at various stages of production are crucial to identify any defects early, ensuring only top-quality products reach the market.

35mm hose clamp manufacturer

Importance of Quality Control

Quality control is paramount in the manufacturing of hose clamps. A poorly made clamp can lead to leaks, hose failure, and potentially dangerous situations. Therefore, reputable manufacturers implement rigorous testing protocols, including torque testing and tensile strength checks, to guarantee that each clamp meets industry standards. Compliance with certifications such as ISO 9001 further underscores a manufacturer’s commitment to quality.

Market Demand and Trends

The global market for hose clamps is influenced by several factors, including the growth of automotive manufacturing, increasing construction activities, and advancements in plumbing technology. As industries evolve, so do the demands for more sophisticated and reliable fastening solutions. Manufacturers must keep pace with these trends by embracing innovation, such as the development of new materials and designs that enhance performance.

Environmental sustainability is also becoming a significant consideration. Many manufacturers are now exploring eco-friendly materials and production processes that minimize waste and reduce the carbon footprint.

Conclusion

As a critical component in various systems, the 35mm hose clamp must be produced with the highest standards of quality and precision. Manufacturers play a pivotal role in ensuring that these clamps meet the evolving demands of different industries. By focusing on quality control, embracing innovation, and considering environmental impacts, hose clamp manufacturers can position themselves for success in a competitive market. With the right commitment to quality and excellence, they can provide robust solutions that ensure safety and reliability in every application.

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025