- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ສ.ຫ. . 30, 2024 09:32 Back to list

High-Quality Hose Clamps | Reliable Hose Clamp Manufacturing

The Importance of Quality Control in Hose Clamp Factories

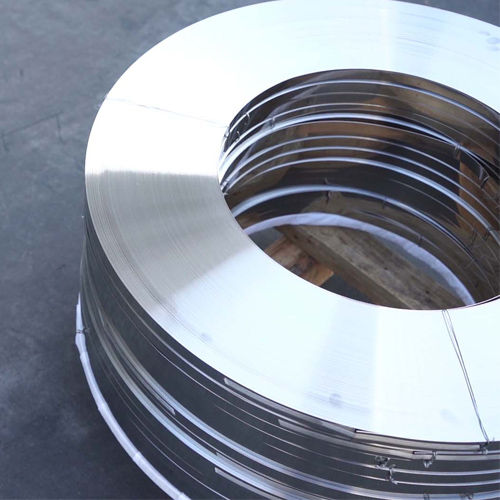

Hose clamps are essential components in various industries, including automotive, industrial machinery, and plumbing systems. They are designed to secure hoses in place, preventing leaks and ensuring the efficient functioning of equipment. Given their critical role, the manufacturing process of hose clamps demands stringent quality control measures to ensure reliability and safety. This article explores the significance of quality control in hose clamp factories and how it impacts the overall production process.

The Importance of Quality Control in Hose Clamp Factories

Once raw materials are sourced, the production process involves several key steps, including cutting, shaping, and finishing the hose clamps. During these مراحل, various quality control measures are implemented. For instance, manufacturers conduct regular inspections to ensure that the dimensions of each clamp meet industry standards. This includes checking the width, width variations, and overall integrity of the clamps. Advanced technologies such as laser measurement tools and automated quality inspection systems are often used to streamline this process, reducing the risk of human error.

1 in hose clamp factories

Moreover, performing rigorous testing is a crucial aspect of quality control in hose clamp manufacturing. Factories often utilize burst pressure tests, torque tests, and corrosion resistance tests to evaluate the strength and durability of the clamps. By simulating real-world conditions, manufacturers can identify any weaknesses in their products before they reach the market. Implementing such testing protocols not only helps improve product quality but also builds trust with customers who rely on these components for safety-critical applications.

Additionally, training employees on quality control standards is vital. A well-trained workforce is essential for maintaining a high level of quality throughout the manufacturing process. Many hose clamp factories invest in continuous training programs to keep their employees updated on the latest industry practices and technologies. This commitment to education enhances the skill set of workers, leading to increased efficiency and output quality.

Finally, maintaining a feedback loop with customers further reinforces quality control efforts. By collecting customer feedback regarding the performance of hose clamps, manufacturers can make informed decisions about product improvements and innovations. A proactive approach to addressing customer concerns not only strengthens relationships but also ensures that the products remain competitive in a rapidly evolving market.

In conclusion, quality control is of utmost importance in hose clamp factories. From the selection of materials to the final testing and customer feedback, every step in the manufacturing process contributes to the overall reliability and effectiveness of hose clamps. As industries continue to evolve, the need for high-quality components becomes even more critical, emphasizing the need for stringent quality control measures in the production of hose clamps.

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025

-

Durable Hose Clamps with GPT-4 Turbo Tech | Secure Sealing

NewsJul.31,2025