- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 25, 2024 19:27 Back to list

Top Manufacturers of Hose Clamps for 3/8 Inch Hoses in the Market Today

Understanding Hose Clamps for 3/8 Hose A Guide for Manufacturers

Hose clamps are essential components in various industries, ensuring the secure attachment of hoses to fittings and preventing leaks in both liquid and gas applications. Among the different types of hoses and clamps, the 3/8 inch hose is one of the most commonly used sizes, especially in automotive, plumbing, and industrial applications. This article explores the significance of hose clamps for 3/8 inch hoses and what manufacturers should consider when choosing and producing these essential tools.

The Role of Hose Clamps

Hose clamps serve the primary function of holding hoses tightly onto fittings or nozzles. They come in various designs, including worm gear clamps, spring clamps, and constant tension clamps. Each type has its advantages, but for 3/8 inch hoses, manufacturers often opt for worm gear clamps due to their adjustable nature and the reliable sealing they provide.

Why 3/8 Inch Hoses are Popular

The 3/8 inch hose size is favored in numerous applications due to its versatility and compatibility with a wide range of fittings. It is commonly used in fuel lines, coolant systems, and HVAC applications. As such, the demand for quality hose clamps that can adequately secure 3/8 inch hoses is significant across many industries.

Key Considerations for Manufacturers

When manufacturing hose clamps for 3/8 hoses, there are several critical factors to consider

hose clamp for 3/8 hose manufacturers

1. Material Selection The choice of material plays a crucial role in the performance and durability of hose clamps. Common materials include stainless steel, carbon steel, and nylon. Stainless steel clamps are particularly popular due to their resistance to corrosion and ability to withstand extreme temperatures.

2. Design Specifications The design of the hose clamp is vital for its functionality. Worm gear clamps, with their threaded screw mechanism, allow for easy adjustments to accommodate different hose diameters and provide a secure fit. Manufacturers should also consider the ease of installation and removal when designing hose clamps.

3. Production Techniques High-quality manufacturing processes ensure the clamps are reliable and durable. Techniques such as precision stamping, forging, and welding should be employed to produce consistent and robust products. Additionally, implementing strict quality control measures during production is essential to meet industry standards.

4. Market Trends Manufacturers should stay informed about trends in the industry, such as advancements in materials and technology. For example, the increasing focus on sustainability has led to the exploration of eco-friendly materials and processes, which could provide a competitive edge.

5. Customization Offering customizable options can attract a broader range of customers. This can include variations in size, materials, and even coatings to enhance corrosion resistance and aesthetics. Many manufacturers now offer custom branding options, which can be an appealing feature for businesses.

Conclusion

In conclusion, hose clamps are critical for ensuring the proper functioning of 3/8 inch hoses, making them an integral part of various applications. Manufacturers must pay close attention to material selection, design, production techniques, market trends, and customization options to create high-quality hose clamps that meet the needs of their customers. By addressing these considerations, manufacturers can enhance their product offerings and contribute to the overall safety and efficiency of hose-related systems. As industries continue to evolve, the demand for reliable hose clamps will remain strong, presenting ongoing opportunities for manufacturers to innovate and expand their reach.

-

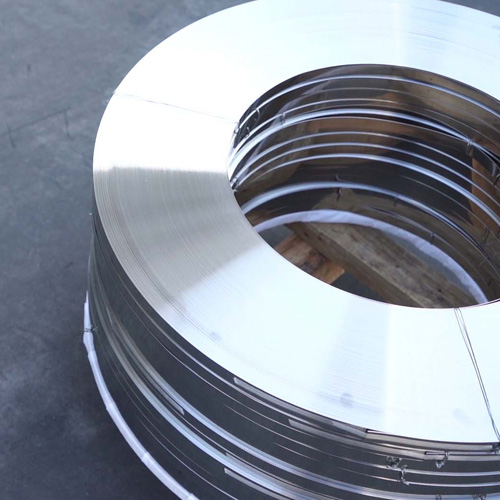

Premium 316L Stainless Steel Strip | Corrosion Resistant

NewsAug.27,2025

-

Durable Adjustable Stainless Steel Hose Clamp - Secure & Rust-Proof

NewsAug.26,2025

-

Premium Adjustable Stainless Steel Hose Clamps for Secure Sealing

NewsAug.25,2025

-

Premium Stainless Steel Hose Clamp - Durable & Rust-Proof

NewsAug.24,2025

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025