- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

6월 . 13, 2024 11:10 Back to list

Hose clamp manufacturing facilities

Unveiling the World of Hose Clamp Factories An Essential Component in Industrial Piping

Hose clamps, those seemingly insignificant yet crucial components in countless industrial applications, play a vital role in securing and maintaining the integrity of fluid transfer systems. The production of these essential fasteners is a specialized process carried out in dedicated hose clamp factories across the globe.

A hose clamp factory is a hub of precision engineering, where raw materials are transformed into high-quality clamps that can withstand immense pressure and diverse environmental conditions. These factories typically operate with state-of-the-art machinery, advanced technology, and a skilled workforce to ensure the manufacture of reliable and durable products.

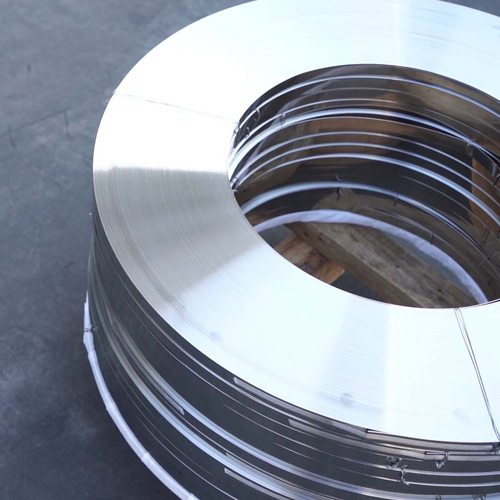

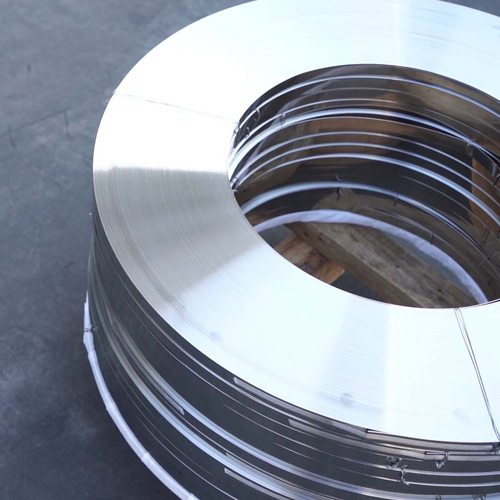

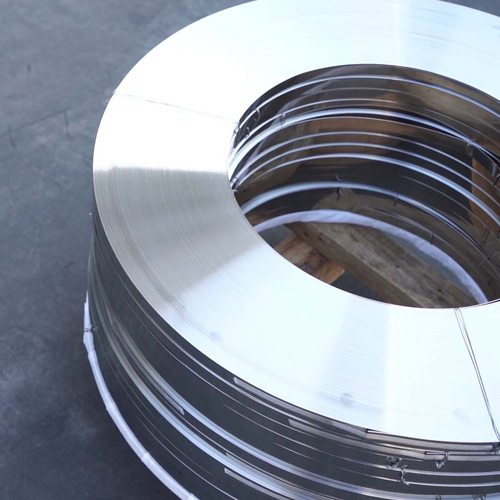

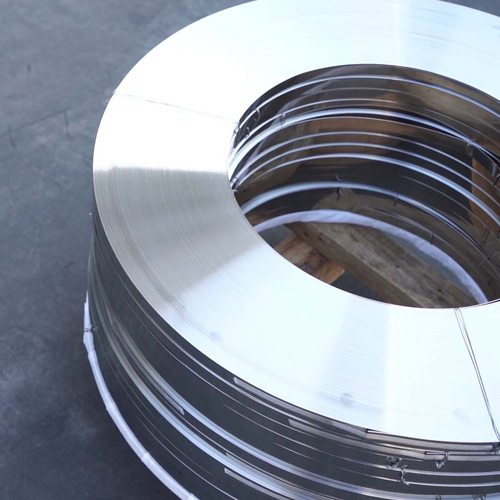

The journey of a hose clamp begins with the selection of raw materials. Most commonly, stainless steel, iron, or aluminum is used due to their strength, corrosion resistance, and flexibility. The metal strips are then cut to specific lengths, depending on the required clamp size. This cutting process is often done using computerized machines for accuracy.

Next, the strips are shaped into their distinctive circular form through a series of pressing and bending operations. In some factories, this is done by hydraulic presses, while others employ more automated processes such as CNC (Computer Numerical Control) machines for increased efficiency.

Once the basic shape is formed, the clamps undergo further refinement. This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts

This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts hose clamp factories. Quality control is an integral part of the process, with rigorous inspections at each stage to ensure compliance with industry standards.

The manufacturing process doesn't end there. The clamps are then subjected to surface treatments, such as galvanization or powder coating, to enhance their durability and protect them from rust. Following this, they are packaged and prepared for shipment to distributors and end-users worldwide.

Hose clamp factories not only focus on production but also invest heavily in research and development. They continually innovate to create new designs that cater to evolving industry needs, whether it's for automotive, agricultural, pharmaceutical, or aerospace applications. They also strive for sustainability, seeking eco-friendly production methods and recycling initiatives.

In conclusion, hose clamp factories are the backbone of an industry that might often go unnoticed but is indispensable to many sectors. Their commitment to precision, quality, and innovation ensures that these small but mighty devices continue to serve their critical function in maintaining the flow in countless systems around the world. The next time you encounter a hose clamp, remember the intricate processes and dedicated work that went into its creation.

hose clamp factories. Quality control is an integral part of the process, with rigorous inspections at each stage to ensure compliance with industry standards.

The manufacturing process doesn't end there. The clamps are then subjected to surface treatments, such as galvanization or powder coating, to enhance their durability and protect them from rust. Following this, they are packaged and prepared for shipment to distributors and end-users worldwide.

Hose clamp factories not only focus on production but also invest heavily in research and development. They continually innovate to create new designs that cater to evolving industry needs, whether it's for automotive, agricultural, pharmaceutical, or aerospace applications. They also strive for sustainability, seeking eco-friendly production methods and recycling initiatives.

In conclusion, hose clamp factories are the backbone of an industry that might often go unnoticed but is indispensable to many sectors. Their commitment to precision, quality, and innovation ensures that these small but mighty devices continue to serve their critical function in maintaining the flow in countless systems around the world. The next time you encounter a hose clamp, remember the intricate processes and dedicated work that went into its creation.

This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts

This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts This includes welding, if necessary, to join the ends, and the addition of any supplementary features like nuts and bolts hose clamp factories. Quality control is an integral part of the process, with rigorous inspections at each stage to ensure compliance with industry standards.

The manufacturing process doesn't end there. The clamps are then subjected to surface treatments, such as galvanization or powder coating, to enhance their durability and protect them from rust. Following this, they are packaged and prepared for shipment to distributors and end-users worldwide.

Hose clamp factories not only focus on production but also invest heavily in research and development. They continually innovate to create new designs that cater to evolving industry needs, whether it's for automotive, agricultural, pharmaceutical, or aerospace applications. They also strive for sustainability, seeking eco-friendly production methods and recycling initiatives.

In conclusion, hose clamp factories are the backbone of an industry that might often go unnoticed but is indispensable to many sectors. Their commitment to precision, quality, and innovation ensures that these small but mighty devices continue to serve their critical function in maintaining the flow in countless systems around the world. The next time you encounter a hose clamp, remember the intricate processes and dedicated work that went into its creation.

hose clamp factories. Quality control is an integral part of the process, with rigorous inspections at each stage to ensure compliance with industry standards.

The manufacturing process doesn't end there. The clamps are then subjected to surface treatments, such as galvanization or powder coating, to enhance their durability and protect them from rust. Following this, they are packaged and prepared for shipment to distributors and end-users worldwide.

Hose clamp factories not only focus on production but also invest heavily in research and development. They continually innovate to create new designs that cater to evolving industry needs, whether it's for automotive, agricultural, pharmaceutical, or aerospace applications. They also strive for sustainability, seeking eco-friendly production methods and recycling initiatives.

In conclusion, hose clamp factories are the backbone of an industry that might often go unnoticed but is indispensable to many sectors. Their commitment to precision, quality, and innovation ensures that these small but mighty devices continue to serve their critical function in maintaining the flow in countless systems around the world. The next time you encounter a hose clamp, remember the intricate processes and dedicated work that went into its creation. Share

Latest news

-

German Style Hose Clamp Manufacturer Quick Lock Worm Gear Hose Clamp Supplier

NewsJul.04,2025

-

Steel Midsole with Stainless Steel – Durable, Lightweight Safety Solutions from Top Factories and Suppliers

NewsJun.24,2025

-

High-Quality Stainless Steel Midsoles in EN Standard – Reliable Factories & Suppliers

NewsJun.10,2025

-

High-Quality Steel Midsole Stainless Steel Factory & Suppliers Durable Safety Solutions

NewsJun.10,2025

-

Steel Plate Midsole Durable Support for Footwear Applications

NewsJun.10,2025

-

Top Tube Clamp Manufacturers Durable Pipe & Hose Solutions

NewsJun.10,2025