- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

កញ្ញា . 25, 2024 16:15 Back to list

stainless steel hose clamps marine supplier

The Importance of Stainless Steel Hose Clamps in Marine Applications

In the marine industry, maintaining the integrity of the vessel's systems is crucial. From fuel lines to exhaust systems, every connection must be secure to prevent leaks that could lead to catastrophic failures or environmental hazards. This is where stainless steel hose clamps come into play. Their strength, durability, and resistance to corrosion make them an essential component for marine suppliers.

What Are Stainless Steel Hose Clamps?

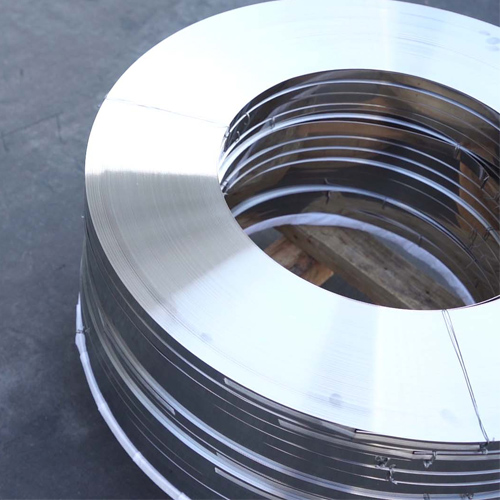

Stainless steel hose clamps are designed to secure hoses onto fittings and ensure that they remain in place under various conditions. These clamps are made from high-quality stainless steel, which provides not only mechanical strength but also resistance to corrosion. This feature is particularly important in marine environments where saltwater, humidity, and varying temperatures can severely affect non-corrosive materials.

Types of Stainless Steel Hose Clamps

There are several types of stainless steel hose clamps available, each designed for specific applications. Some of the most common types include

1. Screw Type Hose Clamps The most widely used kind, these clamps feature a threaded screw mechanism that tightens the clamp around the hose. They are easy to install and adjustable, making them ideal for various hose diameters.

2. Wire Worm Gear Clamps Known for their high strength-to-weight ratio, these clamps use a worm gear to create a strong and reliable hold. They are particularly useful on larger hoses that require a significant amount of torque to maintain their integrity.

3. Spring Clamps These clamps use a spring-loaded mechanism to maintain pressure around the hose. They are best suited for applications where vibration or movement is expected, as they can compensate for any changes in the positioning of the hose.

stainless steel hose clamps marine supplier

4. T-Bolt Clamps Used primarily in high-pressure applications, T-bolt clamps provide even pressure distribution around the hose, preventing damage to both the hose and the fitting.

Benefits of Using Stainless Steel Hose Clamps in Marine Settings

1. Corrosion Resistance The primary benefit of stainless steel is its resistance to corrosion. For marine applications, where exposure to saltwater is inevitable, using stainless steel hose clamps extends the life of the clamps and prevents premature failure.

2. Durability Stainless steel is known for its strength, making these clamps highly durable. They can withstand harsh environmental conditions, physical impacts, and high levels of pressure.

3. Versatility Stainless steel hose clamps can be used in a variety of applications, from securing exhaust systems to holding fuel lines. Their versatility makes them a go-to choice for marine suppliers.

4. Easy Installation and Removal The design of most stainless steel hose clamps allows for straightforward installation and removal. This ease of use saves valuable time during repairs or routine maintenance.

5. Cost-Effectiveness While stainless steel hose clamps may have a higher initial cost than their plastic counterparts, their longevity and durability make them a more cost-effective option in the long run.

Conclusion

When it comes to marine applications, using high-quality stainless steel hose clamps is not just a matter of convenience; it is a necessity for ensuring the safety and efficiency of the vessel. Marine suppliers must prioritize sourcing durable, corrosion-resistant clamps to meet the rigorous demands of marine environments. By investing in stainless steel hose clamps, boat owners and operators can ensure the longevity and reliability of their equipment, providing peace of mind during every voyage. As the marine industry continues to evolve, the importance of quality materials, such as stainless steel hose clamps, will remain paramount.

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025