- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ធ្នូ . 10, 2024 09:51 Back to list

hps hose clamps factories

Understanding HPS Hose Clamps Factories An Overview

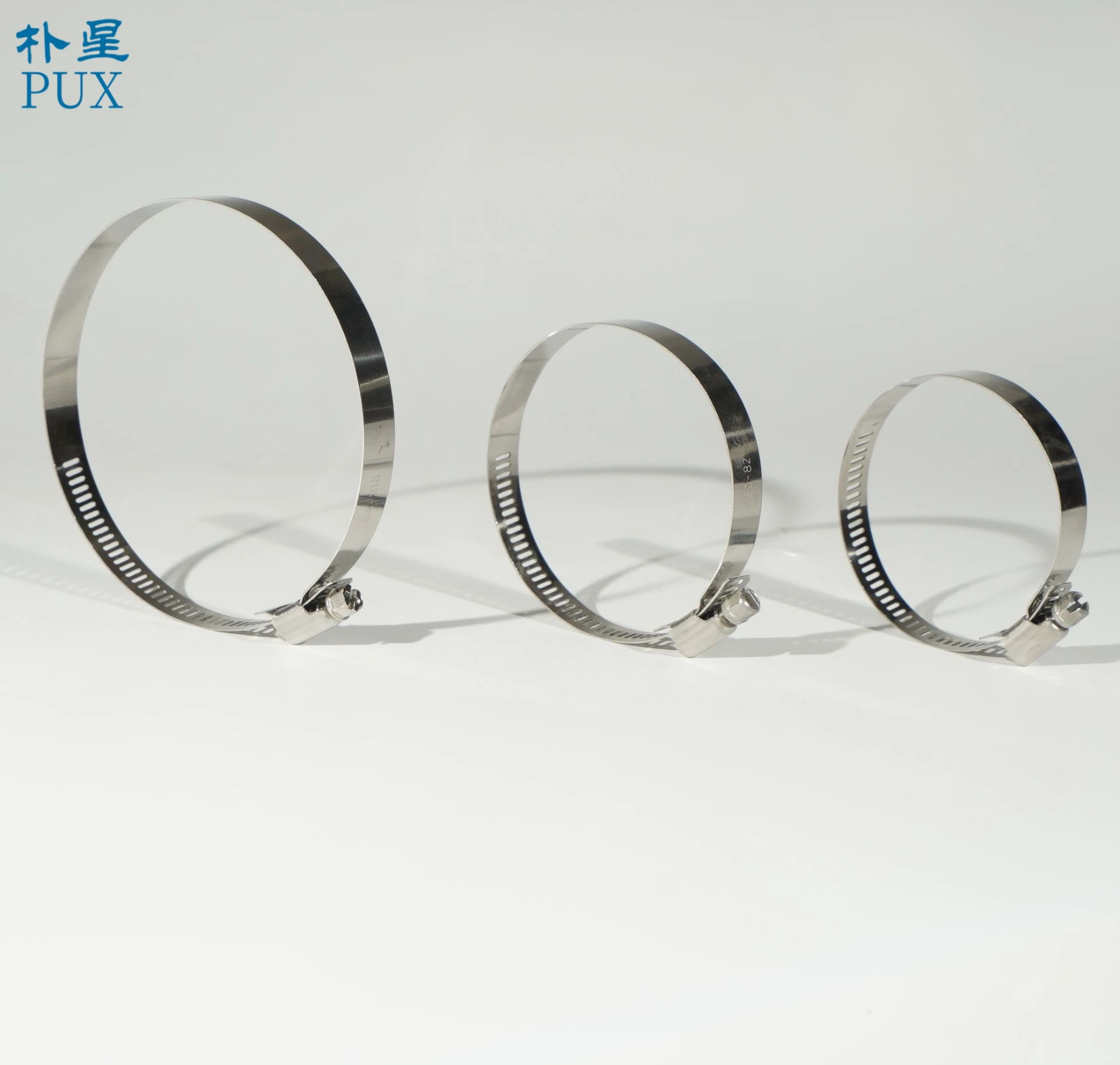

Hose clamps are essential components in various industries, from automotive to industrial applications. They play a crucial role in securing hoses tightly to fittings, preventing leaks, and ensuring the efficient functioning of systems. Among the myriad of manufacturers producing hose clamps, HPS (High-Performance Silicone) stands out for its commitment to quality and performance. This article delves into the significance of HPS hose clamps factories, their manufacturing processes, and the impact of their products on various sectors.

The Importance of Hose Clamps

Hose clamps are designed to provide tight connections for hoses, ensuring they remain securely attached to their fittings under pressure. Their applications are vast, including in automotive systems where they secure coolant, vacuum, and fuel hoses; in HVAC systems where they hold ducting together; and in industrial settings where fluid transfer is critical. The reliability and durability of hose clamps are crucial for system performance, making the choice of a quality manufacturer vital.

HPS A Leader in Hose Clamp Manufacturing

HPS has carved a niche in the hose clamp market with a focus on high-performance products. The company’s commitment to excellence is evident in its manufacturing processes, which utilize advanced technology and high-grade materials. HPS factories are equipped with state-of-the-art machinery that allows for precision manufacturing, ensuring that every hose clamp produced meets industry standards.

The design and materials used in HPS hose clamps play a significant role in their performance. The company uses stainless steel and other corrosion-resistant materials that ensure longevity and reliability, even in the most demanding environments. This focus on material quality translates to clamps that can withstand high pressure, extreme temperatures, and chemical exposure, making them suitable for a wide range of applications.

Manufacturing Processes in HPS Factories

The manufacturing process at HPS facilities is streamlined to maintain efficiency while ensuring top-notch quality. It begins with the selection of raw materials, followed by a series of fabrication steps, including cutting, shaping, and assembling the clamps. Each step is meticulously monitored to prevent defects and guarantee consistency in the final products.

hps hose clamps factories

Automation plays a significant role in the manufacturing process, with modern machinery allowing for high-volume production without sacrificing quality. HPS factories employ skilled technicians who oversee the machinery, ensuring that production runs smoothly and adhering to strict quality control measures.

Once the clamps are manufactured, they undergo rigorous testing to verify their performance under various conditions. Tests may include pressure tests, corrosion resistance tests, and tensile strength assessments, ensuring that each clamp performs as intended before it reaches the market.

Environmental Responsibility and Sustainability

In today's manufacturing landscape, environmental responsibility is a key consideration. HPS is committed to minimizing its environmental footprint through sustainable practices in its factories. This includes recycling waste materials, using energy-efficient machinery, and minimizing water usage. By adopting these practices, HPS not only reduces its impact on the environment but also appeals to eco-conscious consumers and businesses.

The Impact of HPS Hose Clamps

The impact of HPS hose clamps on various industries cannot be overstated. Their reliable performance enhances the functionality of automotive systems, contributes to the efficiency of industrial operations, and ensures the safety of HVAC systems. By investing in high-quality clamps, businesses can reduce the risk of leaks and failures, subsequently lowering maintenance costs and increasing overall operational efficiency.

Additionally, HPS hose clamps are recognized for their versatility. They come in various sizes and designs, catering to different applications across sectors. This adaptability makes them a preferred choice for engineers and manufacturers alike.

Conclusion

HPS hose clamps factories exemplify the fusion of advanced manufacturing techniques and a commitment to quality. The role of hose clamps in ensuring the reliability of various systems cannot be underestimated, and HPS has established itself as a leader in this essential market segment. Through continued innovation and a focus on sustainable practices, HPS is poised to meet the evolving demands of industries ranging from automotive to aerospace. As businesses increasingly prioritize quality and reliability, HPS hose clamps will undoubtedly continue to play a vital role in supporting systems worldwide.

-

Large Stainless Steel Adjustable American Type Hose Clamp | Hebei Pux Alloy Technology Co., Ltd

NewsAug.05,2025

-

Quality 201 Stainless Steel Strip | Durable & Cost-Effective

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025