- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

ធ្នូ . 17, 2024 15:44 Back to list

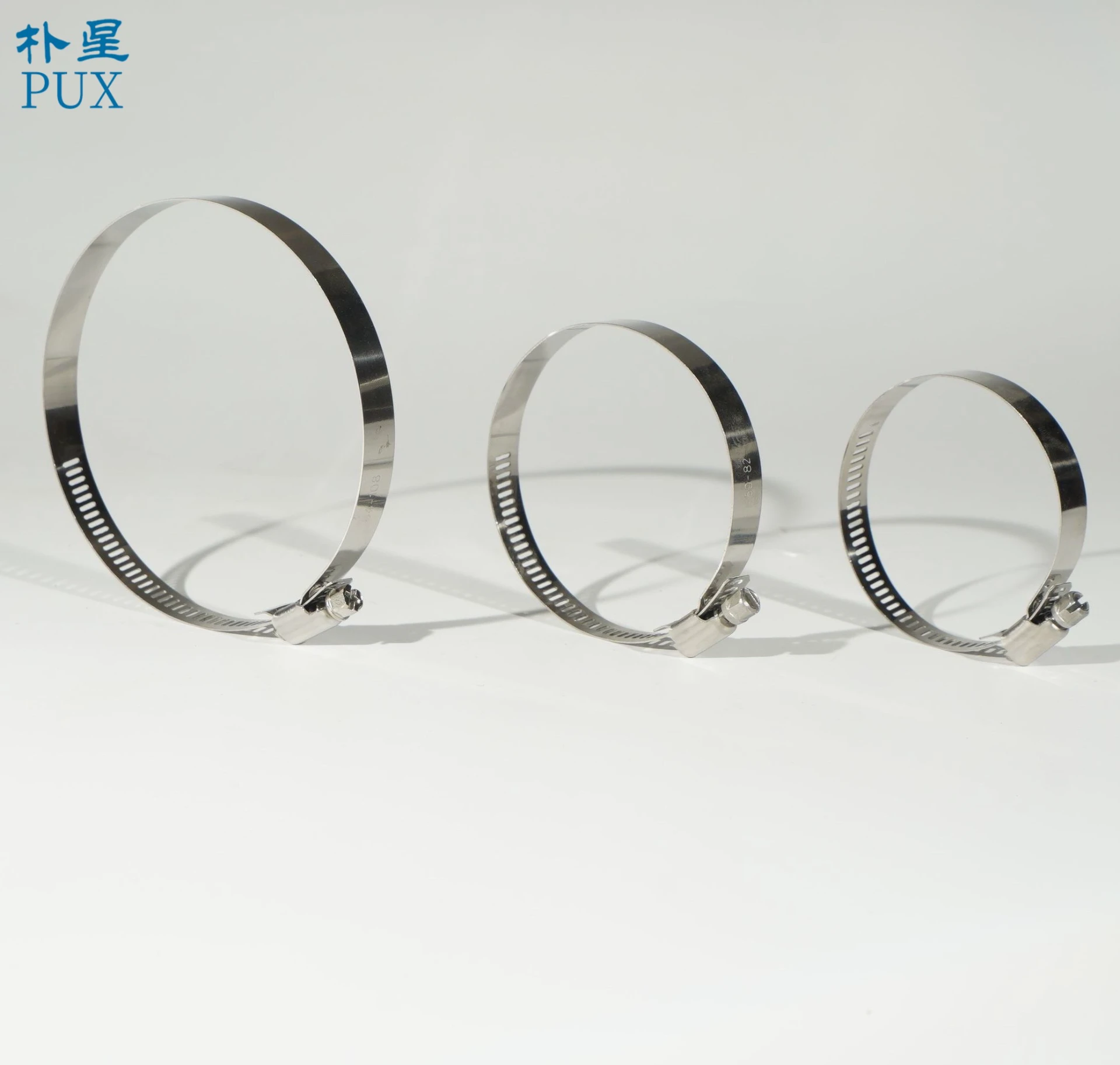

hose clamp for radiator factories

Exploring the World of Hose Clamps for Radiator Factories

Hose clamps are essential components in various industries, especially in automotive manufacturing where they play a critical role in connecting hoses to fittings and ensuring leak-proof seals. Among the numerous applications of hose clamps, their use in radiator assembly is particularly significant. Radiators are vital for vehicle cooling systems, and the reliability of the connections made with hose clamps directly affects the engine's performance and longevity. This article delves into the world of hose clamps specifically designed for radiator factories, exploring their types, manufacturing processes, and the importance of quality assurance.

Types of Hose Clamps

Hose clamps come in various types, each suited for specific applications and requirements. The most common types used in radiator factories include

1. Stainless Steel Hose Clamps Known for their strength and corrosion resistance, stainless steel clamps are ideal for high-temperature environments found in radiators. They offer durability and longevity, making them a favorite among manufacturers.

2. Worm Gear Clamps These clamps are adjustable and consist of a metal band with a screw mechanism that tightens the band around the hose. They provide excellent sealing capabilities and are widely used in automotive applications.

3. Spring Clamps Spring clamps are designed to provide constant pressure on the hose, accommodating changes in temperature and pressure. Their simple design and reliable performance make them popular for radiator applications.

4. Pinch Clamps Often made from steel or aluminum, pinch clamps are efficient for situations where space is limited. They're typically crimped around the hose and can create a strong seal without the need for screws.

Manufacturing Processes

The production of hose clamps involves several stages, each crucial for ensuring that the final product meets the necessary standards for durability and performance. The typical manufacturing process includes

hose clamp for radiator factories

1. Material Selection The choice of materials, such as stainless steel or galvanized steel, is vital for creating hose clamps that can withstand the harsh conditions typical of automotive applications.

2. Forming and Cutting Raw materials are then cut into specified lengths and shaped into bands. This initial shaping is critical for ensuring that the clamps can easily fit around hoses of varying diameters.

3. Welding and Assembly For some types of clamps, components are welded together to form a secure unit. For adjustable clamps, mechanisms such as screws and gears are assembled to allow for expansion and contraction.

4. Finishing The clamps undergo surface treatment processes, such as galvanization or polishing, to enhance their resistance to corrosion and improve their aesthetic appeal.

5. Quality Control Quality assurance is a critical step that involves rigorous testing of the clamps under various conditions. Manufacturers must ensure that the clamps meet industry standards to prevent failures that could lead to significant damage or safety hazards.

Importance of Quality Assurance

In radiator factories, where the efficiency and reliability of components directly impact vehicle performance, the importance of high-quality hose clamps cannot be overstated. Poor-quality hose clamps can lead to coolant leaks, overheating engines, and ultimately expensive repairs. Therefore, manufacturers must invest in stringent quality control measures, including comprehensive testing and certification processes.

Conclusion

The hose clamp market for radiator factories plays a vital role in the automotive industry, ensuring reliable and safe connections in crucial cooling systems. With diverse types of clamps available and detailed manufacturing processes in place, the focus remains on quality assurance to deliver products that meet the stringent demands of modern vehicles. As technology advances and industry standards evolve, the hose clamp sector will continue to innovate, ensuring that automotive performance and safety remain at the forefront of manufacturing practices. Through these efforts, hose clamps will continue to be a cornerstone of reliable radiator assemblies, contributing significantly to the efficiency and safety of our vehicles on the road.

-

Heavy Duty Hose Clamp – Durable Stainless Steel Automotive Tube Clip

NewsJul.26,2025

-

High Quality Precision Stainless Steel Strip for Industrial Use

NewsJul.25,2025

-

Black Rubber Hose Clamp with Rubber Lined & Insulated Design for Secure Fitting

NewsJul.24,2025

-

High Quality Steel Stainless Midsole for Safety Shoes Supplier

NewsJul.23,2025

-

High Quality Hose Clamps Mini Clips - German Style & Stainless Steel

NewsJul.22,2025

-

High Quality Steel Midsoles in EN Standard | Safety Footwear

NewsJul.22,2025